Factors Influencing PCB Cost

Several key factors come into play when determining the cost of a basic PCB. These include:

- PCB Size and Complexity

- Number of Layers

- Material Selection

- Manufacturing Quantity

- Surface Finish

- Additional Features and Requirements

Let’s dive deeper into each of these factors to understand how they impact the overall cost of your PCB.

PCB Size and Complexity

The size and complexity of your PCB design have a significant impact on its manufacturing cost. Generally, larger PCBs with more intricate designs and smaller trace widths will be more expensive to produce. This is because they require more material, precision, and advanced manufacturing techniques.

PCB sizes are typically categorized based on their dimensions:

| Size Category | Dimensions (mm) |

|---|---|

| Small | < 100 x 100 |

| Medium | 100 x 100 to 200 x 200 |

| Large | > 200 x 200 |

As a general rule of thumb, the larger the PCB, the higher the manufacturing cost. However, it’s important to note that the cost per unit area decreases as the PCB size increases, making larger PCBs more cost-effective in terms of price per square centimeter.

PCB complexity is determined by several design aspects, such as the number of components, trace width and spacing, and the presence of advanced features like blind and buried vias. More complex designs require advanced manufacturing processes, leading to higher costs.

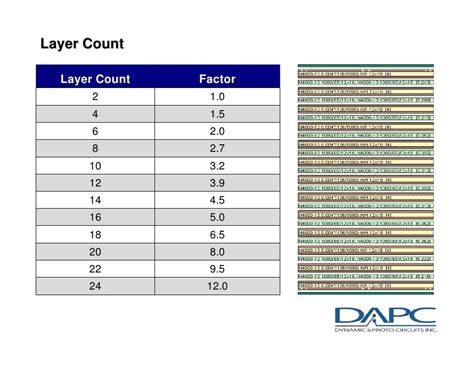

Number of Layers

The number of layers in your PCB is another crucial factor that affects its cost. PCBs can be categorized based on the number of conductive layers:

| Layer Count | Description |

|---|---|

| Single Layer | One conductive layer, typically used for simple designs |

| Double Layer | Two conductive layers, one on each side of the substrate |

| Multi-Layer | Three or more conductive layers, alternating with insulating layers |

As the number of layers increases, so does the manufacturing complexity and cost. Each additional layer requires more material, processing time, and precision to ensure proper alignment and connectivity between layers.

Here’s a rough estimate of how the number of layers affects the cost of a basic PCB:

| Layer Count | Cost Multiplier |

|---|---|

| Single Layer | 1x |

| Double Layer | 1.5x to 2x |

| 4-Layer | 2x to 3x |

| 6-Layer | 3x to 4x |

| 8-Layer and above | 4x and higher |

Keep in mind that these are approximate figures, and the actual cost multipliers may vary depending on the manufacturer and other design factors.

Material Selection

The choice of materials for your PCB substrate and copper layers also plays a role in determining the manufacturing cost. The most common PCB substrate materials are:

- FR-4: A composite material made of woven fiberglass and epoxy resin, known for its durability, electrical insulation, and reasonable cost.

- High-Tg FR-4: A variant of FR-4 with improved thermal properties, suitable for high-temperature applications.

- Polyimide: A high-performance material with excellent thermal stability and chemical resistance, often used in aerospace and military applications.

- Aluminum: Used for PCBs that require better heat dissipation, such as high-power LED boards.

Among these options, FR-4 is the most cost-effective and widely used material for basic PCBs. High-Tg FR-4, polyimide, and aluminum substrates are more expensive due to their superior properties and specialized manufacturing requirements.

The thickness of the copper layers also affects the PCB cost. Thicker copper layers (e.g., 2 oz or 3 oz) are more expensive than the standard 1 oz copper layer, as they require more material and processing time.

Manufacturing Quantity

The number of PCBs you order has a significant impact on the unit cost. PCB manufacturing involves several fixed costs, such as tooling, setup, and design verification. As the order quantity increases, these fixed costs are spread across more units, resulting in a lower cost per PCB.

Here’s an example of how the unit cost decreases with increasing order quantity:

| Quantity | Unit Cost |

|---|---|

| 1-10 | $100 |

| 11-50 | $50 |

| 51-100 | $30 |

| 101-500 | $20 |

| 501-1000 | $15 |

| 1000+ | $10 |

These prices are for illustrative purposes only and may vary significantly based on your specific PCB design and the manufacturer you choose. However, the general trend of decreasing unit cost with increasing quantity holds true.

It’s essential to have a clear idea of your expected production volume when requesting quotes from PCB manufacturers. This will help you obtain accurate pricing and make informed decisions about your PCB design and manufacturing strategy.

Surface Finish

The surface finish on your PCB’s exposed copper pads and traces serves two primary purposes: protecting the copper from oxidation and facilitating solderability during assembly. The choice of surface finish affects both the performance and the cost of your PCB.

Common surface finish options include:

- HASL (Hot Air Solder Leveling): A tin-lead alloy is applied to the exposed copper, providing good solderability at a low cost.

- Lead-Free HASL: Similar to HASL but uses a lead-free solder alloy to comply with RoHS regulations.

- ENIG (Electroless Nickel Immersion Gold): A thin layer of nickel is deposited on the copper, followed by a layer of gold. ENIG offers excellent solderability, corrosion resistance, and durability, but at a higher cost compared to HASL.

- OSP (Organic Solderability Preservative): A thin, organic coating is applied to the copper, providing temporary protection against oxidation. OSP is cost-effective but has a limited shelf life.

- Immersion Silver: A thin layer of silver is deposited on the copper, offering good solderability and durability at a lower cost than ENIG.

The choice of surface finish depends on your specific requirements, such as the desired shelf life, solderability, and compatibility with the assembly process. HASL and OSP are the most cost-effective options, while ENIG and Immersion Silver offer superior performance at a higher cost.

Additional Features and Requirements

Apart from the basic PCB design and manufacturing aspects, several additional features and requirements can impact the overall cost:

- Solder Mask: A polymer layer applied over the PCB to protect the copper traces from accidental solder bridging. Solder mask is available in various colors, with green being the most common and cost-effective option.

- Silkscreen: A layer of text and symbols printed on the PCB for component identification and assembly guidance. White is the standard color for silkscreen, but other colors are available at a slightly higher cost.

- Controlled Impedance: For high-speed or RF applications, the PCB may require controlled impedance traces to maintain signal integrity. This involves precise control of trace width, spacing, and substrate properties, which adds to the manufacturing cost.

- Via-in-Pad: Placing vias directly under component pads to save space and improve routing density. Via-in-pad requires additional processing and increases the manufacturing cost.

- Blind and Buried Vias: Vias that connect inner layers without being visible on the outer layers of the PCB. These require specialized drilling and plating processes, resulting in higher costs compared to through-hole vias.

- UL Certification: If your PCB needs to meet UL safety standards, additional testing and certification processes are required, which can add to the overall cost.

These additional features and requirements can significantly impact the cost of your PCB, so it’s essential to carefully consider which ones are necessary for your specific application.

Estimating the Cost of a Basic PCB

Now that we’ve covered the main factors influencing PCB cost, let’s estimate the cost of a basic PCB using a hypothetical example.

Assume we need to manufacture a medium-sized, double-layer PCB with the following specifications:

- Size: 150 mm x 100 mm

- Layers: 2

- Material: FR-4

- Copper Thickness: 1 oz

- Surface Finish: Lead-Free HASL

- Solder Mask: Green

- Silkscreen: White

- Quantity: 100 pieces

Using rough industry estimates, the cost breakdown for this PCB might look like this:

| Cost Component | Estimated Cost |

|---|---|

| PCB Fabrication | $500 |

| Solder Mask and Silkscreen | $150 |

| Surface Finish | $100 |

| Tooling and Setup | $200 |

| Shipping and Handling | $50 |

| Total Cost | $1000 |

| Cost per PCB | $10 |

Keep in mind that this is a simplified example, and actual costs may vary significantly based on your specific requirements and the manufacturer you choose. It’s always a good idea to request quotes from multiple PCB manufacturers to get a more accurate picture of the costs involved.

FAQ

- What is the minimum order quantity for PCBs?

-

The minimum order quantity varies between manufacturers but typically ranges from 5 to 100 pieces. Some manufacturers may offer lower minimum quantities but at a higher cost per unit.

-

How long does it take to manufacture a basic PCB?

-

The lead time for PCB manufacturing depends on the complexity of your design and the manufacturer’s workload. For a basic PCB, the lead time can range from 1 to 3 weeks, but it’s best to consult with your chosen manufacturer for a more accurate estimate.

-

Can I get a discount for larger order quantities?

-

Yes, most PCB manufacturers offer volume discounts for larger order quantities. The discount structure varies between manufacturers, so it’s essential to request quotes for your specific quantity requirements.

-

What file formats are required for PCB manufacturing?

-

The most common file formats for PCB manufacturing are Gerber files (RS-274X) and drill files (Excellon). These files contain all the necessary information for fabricating your PCB, including copper layers, solder mask, silkscreen, and drill data.

-

How can I reduce the cost of my PCB?

- To reduce the cost of your PCB, consider the following tips:

- Minimize the PCB size and complexity

- Use a standard material like FR-4

- Stick to a double-layer design if possible

- Choose a cost-effective surface finish like HASL or OSP

- Opt for standard solder mask and silkscreen colors

- Order larger quantities to take advantage of volume discounts

- Avoid unnecessary features like blind and buried vias

Conclusion

Determining the cost of a basic PCB involves considering various factors, such as size, complexity, number of layers, material selection, manufacturing quantity, surface finish, and additional features. By understanding how these factors influence the cost, you can make informed decisions about your PCB design and manufacturing strategy.

When estimating the cost of your PCB, it’s crucial to obtain quotes from multiple manufacturers and provide them with detailed specifications of your requirements. This will help you get a more accurate picture of the costs involved and enable you to select the most suitable manufacturer for your project.

By following the tips mentioned in this article and working closely with your chosen PCB manufacturer, you can optimize your design for cost-effectiveness without compromising on quality and functionality.

No responses yet