What is FR4?

FR4 is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. The “FR” in FR4 stands for “Flame Retardant,” indicating its ability to resist the spread of flames and self-extinguish when the heat source is removed. The “4” represents the specific grade of flame retardancy, which is the highest among the FR grades.

Composition of FR4

The primary components of FR4 are:

- Fiberglass cloth: Woven glass fibers provide mechanical strength and dimensional stability to the material.

- Epoxy resin: A thermosetting polymer that acts as a binder and provides excellent electrical insulation properties.

- Flame retardant additives: Chemicals added to the epoxy resin to enhance its flame-retardant properties.

The Manufacturing Process of FR4

The manufacturing process of FR4 involves several stages, each contributing to the final properties of the material. Let’s explore these stages in detail.

Stage 1: Preparing the Fiberglass Cloth

The first stage in FR4 manufacturing is the preparation of the fiberglass cloth. The glass fibers are woven into a fabric using a specific pattern, typically a plain weave or a twill weave. The choice of weave pattern depends on the desired mechanical and electrical properties of the final product.

| Weave Pattern | Characteristics |

|---|---|

| Plain Weave | – Simple and cost-effective – Good dimensional stability |

| Twill Weave | – Higher mechanical strength – Better drape and conformability |

Stage 2: Impregnation with Epoxy Resin

Once the fiberglass cloth is prepared, it undergoes a process called impregnation. The cloth is dipped into a bath containing a mixture of epoxy resin and flame-retardant additives. The additives, such as bromine compounds or phosphorus-based compounds, enhance the flame-retardant properties of the material.

The impregnation process ensures that the epoxy resin thoroughly penetrates the fiberglass cloth, filling the gaps between the glass fibers. This step is crucial for achieving a strong bond between the fiberglass and the resin, resulting in a homogeneous material with excellent mechanical and electrical properties.

Stage 3: Drying and B-Staging

After impregnation, the fiberglass cloth is passed through a series of heated rollers to remove excess resin and ensure a uniform distribution of the resin throughout the fabric. This process is known as drying.

Following the drying process, the impregnated fiberglass cloth undergoes a step called B-staging. During B-staging, the material is heated to a specific temperature, typically between 120°C and 150°C, for a controlled period. This process partially cures the epoxy resin, bringing it to a semi-solid state. The B-staged material, also known as prepreg, is then cooled and stored for further processing.

Stage 4: Lamination

The lamination stage involves stacking multiple layers of B-staged prepreg and copper foil in a specific sequence. The number of layers and the arrangement of copper foil depend on the desired thickness and electrical properties of the final PCB.

The stack is then placed in a lamination press, where it is subjected to high pressure and temperature, typically around 180°C to 200°C. Under these conditions, the epoxy resin fully cures, bonding the layers together and creating a solid, compact laminate.

Stage 5: Finishing and Cutting

After lamination, the FR4 laminate undergoes a series of finishing processes to achieve the desired surface finish and dimensions. These processes may include:

- Surface grinding: To achieve a smooth and uniform surface finish.

- Drilling: To create holes for component mounting and interconnections.

- Cutting: To trim the laminate to the required dimensions.

The finished FR4 laminate is then ready for further processing in the PCB manufacturing process, such as copper patterning, solder mask application, and component assembly.

Properties and Advantages of FR4

FR4 exhibits several desirable properties that make it a popular choice for PCB manufacturing. Some of the key properties and advantages of FR4 include:

- Excellent electrical insulation: FR4 has a high dielectric strength, making it an ideal insulator for electrical circuits.

- Mechanical strength: The combination of fiberglass and epoxy resin provides FR4 with good mechanical strength and rigidity.

- Flame retardancy: The flame-retardant additives in FR4 prevent the spread of flames and ensure self-extinguishing properties.

- Thermal stability: FR4 maintains its mechanical and electrical properties over a wide temperature range, typically from -50°C to 130°C.

- Moisture resistance: FR4 has low moisture absorption, which helps maintain its dimensional stability and prevents warping.

- Cost-effectiveness: FR4 offers a balance of performance and cost, making it an economical choice for PCB manufacturing.

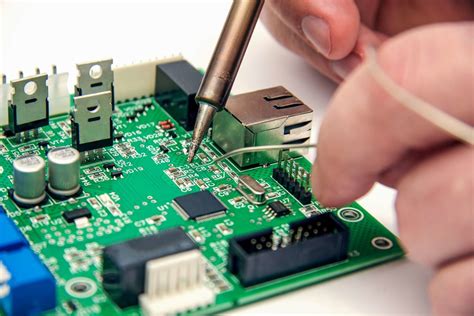

Applications of FR4 in PCB Manufacturing

FR4 finds widespread applications in various industries that rely on PCB technology. Some of the common applications include:

- Consumer electronics: FR4 is used in the PCBs of smartphones, laptops, televisions, and other consumer electronic devices.

- Automotive electronics: PCBs made with FR4 are used in automotive control systems, infotainment systems, and sensors.

- Industrial equipment: FR4-based PCBs are employed in industrial control systems, power supplies, and automation equipment.

- Medical devices: FR4 is used in the PCBs of medical instruments, monitoring systems, and diagnostic equipment.

- Telecommunications: FR4 is utilized in the PCBs of routers, switches, and other networking equipment.

Frequently Asked Questions (FAQ)

-

Q: What does FR stand for in FR4?

A: FR stands for “Flame Retardant,” indicating the material’s ability to resist the spread of flames and self-extinguish when the heat source is removed. -

Q: What is the difference between FR4 and other PCB materials?

A: FR4 differs from other PCB materials in its composition and properties. It is made of woven fiberglass impregnated with epoxy resin and flame-retardant additives, providing excellent electrical insulation, mechanical strength, and flame retardancy. -

Q: Can FR4 be used for high-frequency applications?

A: While FR4 is suitable for many general-purpose applications, it may not be the best choice for high-frequency applications due to its dielectric losses. For high-frequency PCBs, materials with lower dielectric loss, such as Rogers laminates, are often preferred. -

Q: Is FR4 environmentally friendly?

A: FR4 itself is not considered environmentally friendly due to the presence of flame-retardant additives, which can be harmful if not properly disposed of. However, efforts are being made to develop more eco-friendly alternatives, such as halogen-free flame retardants. -

Q: What is the typical thickness of FR4 used in PCBs?

A: FR4 laminates are available in various thicknesses, typically ranging from 0.2mm to 3.2mm. The choice of thickness depends on the specific requirements of the PCB, such as the number of layers, component size, and mechanical strength needed.

Conclusion

FR4 is a crucial material in the PCB manufacturing industry, offering a combination of excellent electrical insulation, mechanical strength, and flame retardancy. The manufacturing process of FR4 involves the preparation of fiberglass cloth, impregnation with epoxy resin, drying, B-staging, lamination, and finishing. The resulting FR4 laminate serves as the foundation for the fabrication of PCBs used in a wide range of electronic applications, from consumer devices to industrial equipment.

Understanding the manufacturing process and properties of FR4 is essential for PCB designers and manufacturers to make informed decisions and ensure the reliability and performance of their products. As technology advances and new challenges arise, the PCB industry continues to innovate and develop new materials and processes to meet the ever-evolving demands of the electronics industry.

No responses yet