What is PCB tracing?

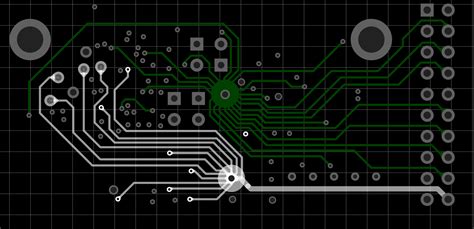

PCB tracing is the process of following the electrical pathways on a printed circuit board to understand its functionality, identify potential issues, or make necessary repairs. It involves examining the board’s layout, components, and connections to create a clear picture of how the circuit operates.

Why is PCB tracing important?

PCB tracing is essential for several reasons:

-

Troubleshooting: When an electronic device malfunctions, tracing the PCB can help identify the root cause of the problem, such as a faulty component or a broken connection.

-

Reverse engineering: If you need to understand how a particular PCB works without access to its schematic or design files, tracing the board can help you recreate the circuit diagram.

-

Modification and repairs: If you want to modify or repair a PCB, tracing allows you to identify the correct points for intervention without damaging the board or its components.

Tools for PCB tracing

To effectively trace a PCB, you’ll need the following tools:

-

Multimeter: A multimeter is an essential tool for measuring voltage, current, and resistance at various points on the PCB. It helps you verify the proper functioning of components and connections.

-

Oscilloscope: An oscilloscope allows you to visualize and analyze electrical signals on the PCB, which is particularly useful for debugging complex circuits or identifying timing issues.

-

Magnifying glass or microscope: A magnifying glass or microscope helps you inspect the PCB closely, making it easier to identify small components, trace thin traces, or spot potential defects.

-

Schematic or board view software: Software tools like KiCad, Eagle, or Altium Designer can be used to create or view PCB schematics and board layouts, which can aid in the tracing process.

-

Soldering iron and desoldering tools: If you need to remove or replace components during the tracing process, a soldering iron and desoldering tools (such as a solder sucker or desoldering braid) are necessary.

Preparing for PCB tracing

Before you start tracing a PCB, it’s important to take the following preparatory steps:

-

Clean the board: Remove any dirt, dust, or residue from the PCB using isopropyl alcohol and a soft brush. This will make it easier to identify components and trace connections.

-

Gather documentation: If available, collect any relevant documentation, such as schematics, board layouts, or component datasheets. These resources can greatly simplify the tracing process.

-

Identify components: Familiarize yourself with the various components on the board, such as resistors, capacitors, diodes, and integrated circuits. Understanding their functions and pinouts will help you navigate the circuit more efficiently.

PCB tracing techniques

There are several techniques you can use to trace a PCB, depending on the complexity of the board and the available resources. Some common techniques include:

-

Visual inspection: Begin by visually inspecting the board, identifying components, and following the traces between them. Use a magnifying glass or microscope to examine small details or densely packed areas.

-

Continuity testing: Use a multimeter to test for continuity between points on the PCB. This helps verify connections and identify potential breaks or short circuits.

-

Signal tracing: Use an oscilloscope to trace signals through the circuit, starting from a known point (such as an input or power supply) and following the path through various components. This technique is particularly useful for analyzing complex circuits or identifying signal integrity issues.

-

Schematic comparison: If you have access to the PCB’s schematic, compare the physical board to the schematic diagram. This helps you understand the intended circuit design and identify any discrepancies or modifications.

-

Reverse engineering: If no schematic is available, you may need to reverse engineer the PCB by carefully tracing the connections and creating a schematic diagram as you go. This process can be time-consuming but is often necessary for understanding or repairing undocumented boards.

Best practices for PCB tracing

To ensure accurate and efficient PCB tracing, follow these best practices:

-

Work methodically: Start from a known reference point (such as a power supply or ground) and work your way through the circuit systematically. This helps prevent confusion and ensures you don’t miss any important connections.

-

Label components and connections: As you trace the PCB, label components and connections using a permanent marker or adhesive labels. This makes it easier to reference specific parts of the circuit later on.

-

Take notes and create diagrams: Document your findings as you trace the PCB, making notes about component functions, pin assignments, and signal paths. Create diagrams or schematics to visualize the circuit more clearly.

-

Double-check your work: Verify your findings by cross-referencing with documentation (if available) or by testing the circuit’s functionality. This helps catch any errors or misinterpretations early on.

-

Practice proper safety precautions: Always ensure the PCB is powered off and discharged before handling it. Use appropriate safety equipment, such as ESD (electrostatic discharge) protection, when working with sensitive components.

Common challenges in PCB tracing

PCB tracing can present several challenges, particularly for complex or densely packed boards. Some common challenges include:

-

Multilayer boards: Modern PCBs often have multiple layers, with traces running between layers through vias. Tracing these boards can be difficult without access to the complete layer stack-up or specialized equipment.

-

Small components and traces: As electronics continue to miniaturize, components and traces become smaller and more densely packed. This can make visual inspection and manual tracing more challenging.

-

Undocumented modifications: If a PCB has been modified or repaired without proper documentation, it can be difficult to understand the changes and their impact on the circuit’s functionality.

-

Damaged or obstructed traces: Physical damage to the PCB, such as scratches or corrosion, can obscure traces and make tracing more difficult. Similarly, components or solder joints can obstruct access to traces.

Advanced PCB tracing techniques

For complex or challenging PCBs, more advanced tracing techniques may be necessary. These include:

-

X-ray imaging: X-ray machines can create detailed images of the PCB, revealing the internal structure and connections between layers. This is particularly useful for multilayer boards or boards with BGA (ball grid array) components.

-

Thermal imaging: Thermal cameras can help identify hot spots or thermal anomalies on the PCB, which can indicate current flow or potential issues.

-

Time-domain reflectometry (TDR): TDR is a technique that uses high-frequency electrical pulses to analyze the impedance and integrity of PCB traces. This can help identify issues such as impedance mismatches or signal reflections.

-

Automated optical inspection (AOI): AOI systems use high-resolution cameras and image processing algorithms to automatically inspect PCBs for defects or deviations from the intended design.

FAQ

-

What is the best way to learn PCB tracing?

The best way to learn PCB tracing is through a combination of studying the fundamentals of electronics, practicing on simple boards, and gradually working up to more complex circuits. Hands-on experience, coupled with a solid understanding of components and circuit design, is key to developing strong PCB tracing skills. -

Can I trace a PCB without a schematic?

Yes, it is possible to trace a PCB without a schematic, but it can be more challenging and time-consuming. In this case, you’ll need to rely on visual inspection, continuity testing, and reverse engineering techniques to understand the circuit’s functionality. -

How do I trace a multilayer PCB?

Tracing a multilayer PCB can be difficult without specialized equipment, such as X-ray machines or layer-by-layer scanners. If you don’t have access to these tools, you may need to rely on visual inspection of the exposed layers, continuity testing, and careful analysis of the board’s construction to understand the connections between layers. -

What should I do if I damage a trace while probing the PCB?

If you accidentally damage a trace while probing the PCB, you can often repair it using a small piece of wire or conductive paint. Carefully solder or apply the conductive material to bridge the damaged section of the trace, ensuring a secure and reliable connection. -

How can I improve my PCB tracing skills?

To improve your PCB tracing skills, practice regularly on a variety of boards, study circuit design principles, and stay up-to-date with the latest tools and techniques. Collaborate with other electronics enthusiasts or professionals to learn from their experiences and insights, and don’t be afraid to take on challenging projects that push your skills to the next level.

| Tool | Purpose |

|---|---|

| Multimeter | Measure voltage, current, and resistance; test continuity |

| Oscilloscope | Visualize and analyze electrical signals |

| Magnifying glass or microscope | Inspect small components and traces |

| Schematic or board view software | Create or view PCB schematics and board layouts |

| Soldering iron and desoldering tools | Remove or replace components during tracing |

| Technique | Description |

|---|---|

| Visual inspection | Identify components and follow traces visually |

| Continuity testing | Test for continuity between points using a multimeter |

| Signal tracing | Trace signals through the circuit using an oscilloscope |

| Schematic comparison | Compare the physical board to the schematic diagram |

| Reverse engineering | Trace connections and create a schematic diagram from the PCB |

In conclusion, PCB tracing is a valuable skill for anyone working with electronics. By understanding the techniques, tools, and best practices involved, you can effectively troubleshoot, repair, and modify PCBs, saving time and resources in the process. With practice and persistence, anyone can develop strong PCB tracing skills and become a more capable electronics professional or enthusiast.

No responses yet