Introduction to PCBA Programming

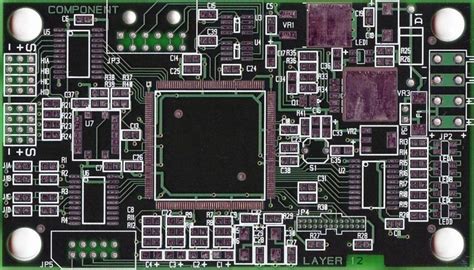

PCBA (Printed Circuit Board Assembly) programming is an essential step in the manufacturing process of electronic devices. It involves the programming of integrated circuits (ICs) on the PCB to ensure that they function as intended. PCBA programming can be a complex and time-consuming process, but it is crucial for the proper functioning of the end product.

In this article, we will explore the concept of free IC programming for PCBA and why it is an opportunity that you don’t want to miss. We will also discuss the benefits of PCBA programming, the different types of ICs that require programming, and the various programming methods available.

What is Free IC Programming for PCBA?

Free IC programming for PCBA refers to the practice of programming ICs on the PCB without any additional cost to the customer. This means that the cost of programming is included in the overall cost of the PCBA Manufacturing process.

Many PCBA manufacturers offer free IC programming as a value-added service to their customers. This is because they understand the importance of programming in the overall functionality of the end product and want to ensure that their customers receive the best possible service.

Benefits of Free IC Programming for PCBA

There are several benefits to free IC programming for PCBA, including:

-

Cost Savings: By including the cost of programming in the overall cost of PCBA manufacturing, customers can save money on their project.

-

Time Savings: Free IC programming can also save time, as the programming is done during the manufacturing process, eliminating the need for additional programming steps.

-

Quality Assurance: When the programming is done by the PCBA manufacturer, they can ensure that the ICs are programmed correctly and that the end product functions as intended.

-

Convenience: Free IC programming is a convenient option for customers who may not have the expertise or resources to program the ICs themselves.

Types of ICs that Require Programming

There are several types of ICs that require programming in the PCBA manufacturing process. These include:

Microcontrollers

Microcontrollers are small computers on a single integrated circuit that contain a processor, memory, and programmable input/output peripherals. They are used in a wide range of applications, from simple household appliances to complex industrial equipment.

Programming a microcontroller involves loading the firmware onto the chip, which contains the instructions that tell the microcontroller how to function. This firmware can be written in a variety of programming languages, including C, C++, and Assembly.

EEPROMs

EEPROMs (Electrically Erasable Programmable Read-Only Memory) are non-volatile memory chips that can be erased and reprogrammed using electrical signals. They are often used to store configuration data, calibration settings, and other information that needs to be retained even when power is removed.

Programming an EEPROM involves writing the desired data to the chip using a programmer or a specialized software tool.

Flash Memory

Flash memory is a type of non-volatile memory that can be erased and rewritten electronically. It is often used in applications where frequent updates or modifications are required, such as in firmware upgrades or data logging.

Programming flash memory involves erasing the existing data and writing new data to the chip using a programmer or software tool.

PCBA Programming Methods

There are several methods for programming ICs on a PCBA, each with its own advantages and disadvantages. The most common methods include:

In-System Programming (ISP)

In-system programming (ISP) is a method of programming ICs directly on the PCBA using a specialized programmer. This method is often used for microcontrollers and other ICs that support ISP.

ISP allows for quick and easy programming of ICs without the need to remove them from the PCBA. However, it requires a specialized programmer and may not be suitable for all types of ICs.

In-Circuit Serial Programming (ICSP)

In-circuit serial programming (ICSP) is a method of programming ICs using a serial interface, such as SPI or I2C. This method is often used for EEPROMs and other ICs that support serial programming.

ICSP allows for programming of ICs without the need for a specialized programmer, as the programming can be done using a microcontroller or other device on the PCBA. However, it may be slower than other programming methods and requires additional hardware and software.

JTAG Programming

JTAG (Joint Test Action Group) programming is a method of programming and debugging ICs using a standardized interface. This method is often used for complex ICs, such as FPGAs and microprocessors.

JTAG programming allows for advanced debugging and testing capabilities, as well as the ability to program ICs that do not support other programming methods. However, it requires a specialized JTAG programmer and may be more complex than other programming methods.

Choosing the Right PCBA Manufacturer for Free IC Programming

When choosing a PCBA manufacturer for your project, it is important to consider their capabilities and experience with IC programming. Here are some factors to consider:

Programming Equipment and Software

A good PCBA manufacturer should have the necessary programming equipment and software to handle a wide range of ICs and programming methods. This includes specialized programmers, such as ISP and JTAG programmers, as well as software tools for programming and debugging.

Experience and Expertise

Experience and expertise are critical when it comes to IC programming. A good PCBA manufacturer should have a team of experienced engineers and technicians who are knowledgeable about the latest programming methods and technologies.

Quality Control and Testing

Quality control and testing are essential to ensure that the programmed ICs function as intended. A good PCBA manufacturer should have rigorous quality control procedures in place, including automated testing and visual inspection.

Customer Support and Communication

Good customer support and communication are important throughout the PCBA manufacturing process, including during IC programming. A good PCBA manufacturer should be responsive to customer inquiries and provide regular updates on the status of the project.

FAQs

1. What is the difference between IC programming and firmware development?

IC programming refers to the process of loading firmware or other software onto an integrated circuit, while firmware development refers to the process of creating the software that will be loaded onto the IC. Firmware development is typically done by software engineers, while IC programming is done by hardware engineers or technicians.

2. Can all ICs be programmed using the same method?

No, different types of ICs require different programming methods. For example, microcontrollers are typically programmed using ISP or ICSP, while EEPROMs may be programmed using ICSP or other serial programming methods. It is important to choose the appropriate programming method for each type of IC.

3. How long does IC programming typically take?

The time required for IC programming can vary depending on the complexity of the IC, the programming method used, and the number of ICs being programmed. Simple ICs may only take a few seconds to program, while more complex ICs may take several minutes or even hours.

4. What are the risks of not properly programming ICs on a PCBA?

If ICs are not properly programmed, the end product may not function as intended or may even be damaged. This can lead to costly rework, delays, and even product recalls. It is important to ensure that ICs are programmed correctly and thoroughly tested before the PCBA is assembled into the final product.

5. Can I program my own ICs for my PCBA project?

While it is possible to program your own ICs, it is often more cost-effective and efficient to outsource this task to a PCBA manufacturer that offers free IC programming. This ensures that the programming is done correctly and efficiently, and frees up your time and resources to focus on other aspects of your project.

Conclusion

Free IC programming for PCBA is an opportunity that you don’t want to miss. By outsourcing the programming of ICs to a qualified PCBA manufacturer, you can save time and money while ensuring that your end product functions as intended.

When choosing a PCBA manufacturer for your project, it is important to consider their capabilities and experience with IC programming, as well as their quality control procedures and customer support.

By taking advantage of free IC programming and choosing the right PCBA manufacturer, you can streamline your manufacturing process and bring your product to market faster and more efficiently.

Table: Comparison of PCBA Programming Methods

| Programming Method | Advantages | Disadvantages |

|---|---|---|

| ISP | Quick and easy programming without removing ICs from PCBA | Requires specialized programmer, may not be suitable for all ICs |

| ICSP | Allows for programming without specialized programmer, uses serial interface | May be slower than other methods, requires additional hardware and software |

| JTAG | Advanced debugging and testing capabilities, can program ICs that don’t support other methods | Requires specialized JTAG programmer, may be more complex than other methods |

No responses yet