Introduction to USB routing

USB (Universal Serial Bus) has become the standard interface for connecting various peripherals to computers and other electronic devices. Proper USB routing is crucial for ensuring reliable data transmission and minimizing signal integrity issues. When designing a 2-layer PCB, routing USB differential pairs can be challenging due to limited space and the need to maintain signal integrity. In this article, we will discuss the key considerations and best practices for USB differential pair routing on a 2-layer board.

Understanding USB differential pairs

USB uses differential signaling, which means that data is transmitted using two signal lines: D+ and D-. These lines carry equal and opposite signals, which helps to cancel out electromagnetic interference (EMI) and maintain signal integrity. The characteristic impedance of a USB differential pair is typically 90Ω ±10%.

USB data rates and signal integrity

USB has evolved over the years, with different versions supporting varying data rates:

| USB Version | Data Rate | Frequency |

|---|---|---|

| USB 1.1 | 1.5 Mbps (Low Speed) / 12 Mbps (Full Speed) | 1.5 MHz / 12 MHz |

| USB 2.0 | 480 Mbps (High Speed) | 480 MHz |

| USB 3.0 | 5 Gbps (SuperSpeed) | 2.5 GHz |

| USB 3.1 | 10 Gbps (SuperSpeed+) | 5 GHz |

As data rates increase, signal integrity becomes more critical. Higher frequencies are more susceptible to impedance mismatches, crosstalk, and other signal integrity issues. Proper USB routing techniques help to mitigate these problems.

PCB stack-up for 2-layer boards

When working with a 2-layer PCB, the typical stack-up consists of a signal layer (top) and a ground plane (bottom). The signal layer is used for routing traces, while the ground plane provides a low-impedance return path for the signals and helps to reduce EMI.

| Layer | Material | Thickness |

|---|---|---|

| Top (Signal) | Copper | 1 oz (35 μm) |

| Substrate | FR-4 | 1.6 mm |

| Bottom (Ground) | Copper | 1 oz (35 μm) |

The thickness of the substrate and the copper weight affect the characteristic impedance of the traces. Thicker substrates and thinner copper weights result in higher characteristic impedances.

Calculating USB differential pair trace width and spacing

To maintain the desired characteristic impedance of 90Ω, you need to calculate the appropriate trace width and spacing for your USB differential pairs. Several factors influence the characteristic impedance, including:

- PCB substrate material (typically FR-4)

- Substrate Thickness

- Copper weight

- Trace width

- Trace spacing

There are various online calculators and PCB design software tools that can help you determine the optimal trace width and spacing based on your PCB stack-up and desired characteristic impedance. For example, using a 1.6 mm FR-4 substrate with 1 oz copper weight, you might end up with the following trace geometry:

- Trace width: 0.2 mm

- Trace spacing: 0.2 mm

Routing guidelines for USB differential pairs

When routing USB differential pairs on a 2-layer board, follow these guidelines to ensure signal integrity:

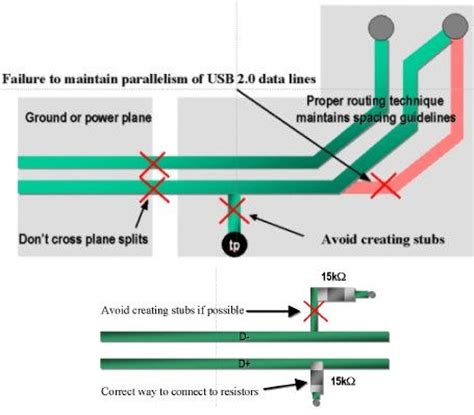

- Keep D+ and D- traces close together and parallel to each other to maintain differential signaling and minimize crosstalk.

- Maintain consistent trace width and spacing throughout the entire length of the differential pair.

- Avoid sharp bends or corners in the traces, as they can cause impedance discontinuities. Use smooth curves or 45-degree angles instead.

- Keep USB traces away from other high-speed signals or sources of EMI to prevent crosstalk and interference.

- Avoid crossing USB traces over split planes or gaps in the ground plane, as this can cause impedance mismatches and signal integrity issues.

- If you need to route USB traces on the bottom layer (ground plane), use a technique called “stitching vias” to maintain the ground reference and minimize impedance discontinuities.

- Ensure that the USB traces have a solid ground reference beneath them on the bottom layer. If necessary, create a ground pour on the top layer and connect it to the bottom ground plane using vias.

- Place decoupling capacitors close to the USB connector to minimize power supply noise and maintain signal integrity.

Length matching and phase skew

To ensure proper differential signaling and minimize phase skew, it’s essential to length-match the D+ and D- traces. Phase skew occurs when there is a time difference between the signals arriving at the receiver, which can cause signal integrity issues and degrade performance.

The maximum allowable length difference between D+ and D- traces depends on the USB version and data rate:

| USB Version | Maximum Length Difference |

|---|---|

| USB 1.1 | 1.5 mm |

| USB 2.0 | 0.15 mm |

| USB 3.0/3.1 | 0.025 mm |

To length-match the USB traces, you can use serpentine routing or add “wiggle room” to the shorter trace to match the length of the longer one. However, be cautious not to introduce too many bends or corners, as they can affect signal integrity.

USB connector placement and routing

When placing USB connectors on your 2-layer board, consider the following:

- Position the USB connector close to the edge of the board to minimize trace lengths and reduce signal integrity issues.

- Ensure that there is enough clearance around the USB connector for the PCB assembly process and to accommodate the USB cable plug.

- Route the USB differential pairs directly from the connector to the USB controller or hub IC, minimizing the trace lengths and avoiding unnecessary turns or vias.

- If you need to route the USB traces through a connector or a series resistor, ensure that both D+ and D- traces pass through the same connector or resistor to maintain differential signaling.

Simulation and testing

Before finalizing your USB routing design, it’s a good idea to perform simulations and test the signal integrity of your differential pairs. Many PCB design software packages include tools for simulating and analyzing USB signals, such as:

- Time-domain reflectometry (TDR) analysis to check for impedance discontinuities

- Frequency-domain analysis to evaluate the frequency response and bandwidth of the USB channel

- Eye diagram analysis to assess the quality of the USB signal and ensure that it meets the required specifications

After fabricating your PCB, perform actual measurements using a high-bandwidth oscilloscope and USB test equipment to validate the signal integrity and performance of your USB implementation.

Frequently Asked Questions (FAQ)

- Can I route USB traces on both layers of a 2-layer board?

-

It’s best to route USB differential pairs entirely on the top layer (signal layer) to maintain a consistent reference plane and avoid impedance discontinuities. If you must route USB traces on the bottom layer, use stitching vias and ensure a solid ground reference.

-

What is the maximum length for USB traces on a 2-layer board?

-

The maximum length for USB traces depends on the USB version and data rate. As a general rule, keep USB traces as short as possible to minimize signal integrity issues. For USB 2.0 (480 Mbps), the maximum recommended trace length is around 5 inches (127 mm).

-

How do I choose the right USB connector for my 2-layer board?

-

Select a USB connector that is compatible with your USB version and PCB thickness. Surface-mount connectors are preferred for 2-layer boards, as they minimize the need for vias and reduce signal integrity issues. Ensure that the connector has a good shielding mechanism to minimize EMI.

-

What are the consequences of not length-matching USB differential pairs?

-

If the USB D+ and D- traces are not length-matched, it can result in phase skew, which can degrade signal integrity and cause data transmission errors. This is particularly critical for high-speed USB versions like USB 3.0 and above.

-

Can I use autorouting for USB differential pairs on a 2-layer board?

- While autorouting can be a useful tool for general PCB routing, it’s not recommended for critical signals like USB differential pairs. Manual routing allows you to have more control over the trace geometry, length matching, and signal integrity. If you must use autorouting, be sure to review and optimize the USB routes manually afterwards.

Conclusion

Routing USB differential pairs on a 2-layer board requires careful consideration of signal integrity, impedance matching, and trace geometry. By following the guidelines and best practices outlined in this article, you can successfully design and implement USB on your 2-layer PCB. Remember to calculate the appropriate trace width and spacing, keep differential pairs close together and parallel, avoid sharp bends and crossing split planes, and length-match the D+ and D- traces. Simulating and testing your USB design is crucial for validating signal integrity and ensuring reliable data transmission. With proper USB routing techniques, you can create robust and high-performance USB interfaces on your 2-layer boards.

No responses yet