What Is a Semiconductor?

Definition and Properties

A semiconductor is a material that has electrical conductivity between that of an insulator and a conductor. Unlike conductors, which allow electrons to flow freely, and insulators, which greatly restrict electron movement, semiconductors can be manipulated to control their conductivity. This unique property makes semiconductors the foundation of modern electronics.

The most common semiconductors are silicon (Si) and germanium (Ge), although other materials like gallium arsenide (GaAs) and silicon carbide (SiC) are also used in specific applications. Semiconductors have the following properties:

- Controllable conductivity

- Sensitivity to temperature, light, and magnetic fields

- Ability to form p-n junctions, which are essential for electronic devices

Intrinsic and Extrinsic Semiconductors

Semiconductors can be classified into two types: intrinsic and extrinsic.

-

Intrinsic Semiconductors: These are pure semiconductor materials without any added impurities. In intrinsic semiconductors, the number of electrons in the conduction band is equal to the number of holes in the valence band. Examples include pure silicon and germanium.

-

Extrinsic Semiconductors: These are semiconductors with added impurities, known as dopants, which alter their electrical properties. Dopants can be either n-type (adding extra electrons) or p-type (creating holes). Extrinsic semiconductors are further classified into:

- n-type semiconductors: Doped with electron-donating impurities like phosphorus or arsenic.

- p-type semiconductors: Doped with electron-accepting impurities like boron or gallium.

| Semiconductor Type | Dopant Type | Majority Charge Carriers |

|---|---|---|

| n-type | Electron-donating (e.g., phosphorus, arsenic) | Electrons |

| p-type | Electron-accepting (e.g., boron, gallium) | Holes |

Applications of Semiconductors

Semiconductors find applications in a wide range of electronic devices, including:

- Diodes

- Transistors

- Integrated circuits (ICs)

- Solar cells

- Light-emitting diodes (LEDs)

- Sensors

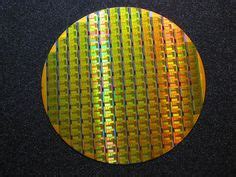

What Is a Wafer?

Definition and Manufacturing Process

A wafer is a thin slice of semiconductor material, typically silicon, used as a substrate for fabricating integrated circuits and other microelectronic devices. Wafers are produced through a process called the Czochralski method, which involves the following steps:

- Melting high-purity silicon in a crucible

- Dipping a seed crystal into the molten silicon

- Slowly pulling the seed crystal out while rotating it, causing the molten silicon to crystallize and form a cylindrical ingot

- Slicing the ingot into thin wafers using a precision saw

- Polishing the wafers to achieve a smooth, mirror-like surface

Wafer Sizes and Thicknesses

Wafers come in various sizes, with the most common being:

| Wafer Size (diameter) | Typical Thickness |

|---|---|

| 100 mm (4 inches) | 525 μm |

| 150 mm (6 inches) | 675 μm |

| 200 mm (8 inches) | 725 μm |

| 300 mm (12 inches) | 775 μm |

| 450 mm (18 inches) | 925 μm |

Larger wafer sizes allow for more chips to be fabricated on a single wafer, reducing production costs. However, transitioning to larger wafer sizes requires significant investments in new manufacturing equipment and facilities.

From Wafer to Chip

After the wafer is produced, it undergoes a series of processing steps to fabricate integrated circuits (ICs) or chips. These steps include:

- Photolithography: Transferring the IC design onto the wafer using light-sensitive materials and masks.

- Etching: Selectively removing material from the wafer to create the desired patterns.

- Doping: Introducing impurities into specific regions of the wafer to modify its electrical properties.

- Insulation and metallization: Adding insulating layers and metal interconnects to create a functional circuit.

- Packaging: Cutting the wafer into individual chips and encasing them in protective packages.

What Is an Integrated Circuit (IC)?

Definition and Structure

An integrated circuit, or IC, is a miniaturized electronic circuit consisting of interconnected electronic components such as transistors, resistors, capacitors, and diodes fabricated onto a single semiconductor substrate, typically silicon. ICs are also known as microchips or simply chips.

The structure of an IC consists of several layers:

- Substrate: The semiconductor wafer on which the circuit is fabricated.

- Active components: Transistors, diodes, and other electronic components that form the circuit’s basic building blocks.

- Interconnects: Metal layers that connect the active components to form a functional circuit.

- Insulating layers: Materials like silicon dioxide (SiO2) or silicon nitride (Si3N4) that electrically isolate the interconnects and components.

- Packaging: The protective enclosure that houses the IC and provides electrical connections to the outside world.

Types of Integrated Circuits

Integrated circuits can be classified into several categories based on their complexity and function:

-

Analog ICs: These ICs process continuous signals and are used in applications such as amplifiers, sensors, and power management.

-

Digital ICs: These ICs work with discrete binary signals (0s and 1s) and are found in logic gates, microprocessors, and memory devices.

-

Mixed-signal ICs: These ICs combine both analog and digital functions on a single chip, such as analog-to-digital converters (ADCs) and digital-to-analog converters (DACs).

-

System-on-a-chip (SoC): These are highly integrated ICs that contain an entire electronic system, including a processor, memory, and peripheral interfaces, on a single chip.

| IC Type | Function | Examples |

|---|---|---|

| Analog | Processing continuous signals | Amplifiers, sensors, power management |

| Digital | Working with discrete binary signals | Logic gates, microprocessors, memory |

| Mixed-signal | Combining analog and digital functions | ADCs, DACs |

| System-on-a-chip | Integrating an entire electronic system | Smartphone SoCs, microcontrollers |

Advantages of Integrated Circuits

Integrated circuits offer several advantages over discrete component circuits:

- Miniaturization: ICs allow for the integration of thousands to billions of components onto a single chip, enabling compact and portable electronic devices.

- Cost-effectiveness: Mass production of ICs leads to lower per-unit costs compared to discrete component circuits.

- Reliability: The miniaturization and integration of components in ICs reduce the number of interconnections, leading to higher reliability.

- Power efficiency: ICs consume less power than equivalent discrete component circuits due to their smaller size and optimized design.

- Speed: The close proximity of components in ICs allows for faster signal propagation and higher operating speeds.

IC Packaging

Once the integrated circuit is fabricated on the wafer, it needs to be packaged to protect it from the environment and provide electrical connections to the outside world. Some common IC package types include:

-

Dual In-line Package (DIP): A rectangular package with two rows of pins on either side. DIP packages are common for through-hole mounting on printed circuit boards (PCBs).

-

Quad Flat Package (QFP): A surface-mount package with pins on all four sides. QFPs are commonly used for microcontrollers and other medium-complexity ICs.

-

Ball Grid Array (BGA): A surface-mount package with an array of solder balls on the bottom for electrical connections. BGAs are used for high-density ICs like microprocessors and FPGAs.

-

Wafer-level Chip-scale Package (WLCSP): A package-less IC where the protective coating and electrical connections are applied directly to the wafer before singulation. WLCSPs are the smallest IC packages available.

| Package Type | Mounting | Pin Count Range | Applications |

|---|---|---|---|

| DIP | Through-hole | 8 to 64 | Low-complexity ICs, hobbyist electronics |

| QFP | Surface-mount | 32 to 256 | Microcontrollers, medium-complexity ICs |

| BGA | Surface-mount | 100 to 1000+ | High-density ICs, microprocessors, FPGAs |

| WLCSP | Direct chip attach | Varies | Ultra-small, low-power ICs |

Relationships Between ICs, Chips, Semiconductors, and Wafers

Now that we’ve explored each term individually, let’s summarize the relationships between ICs, chips, semiconductors, and wafers:

-

Semiconductors are the materials used to fabricate ICs and chips. They have unique electrical properties that make them suitable for controlling the flow of electrons.

-

Wafers are thin slices of semiconductor material, typically silicon, that serve as the substrate for fabricating ICs and chips.

-

Integrated circuits (ICs) are miniaturized electronic circuits consisting of interconnected electronic components fabricated onto a single semiconductor substrate.

-

Chips are another term for integrated circuits, often used interchangeably with ICs.

In essence, semiconductors are the raw materials, wafers are the substrates, and ICs or chips are the end products of the semiconductor manufacturing process.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between an IC and a chip?

A: Integrated circuits (ICs) and chips are essentially the same things. The terms are often used interchangeably to refer to a miniaturized electronic circuit fabricated on a semiconductor substrate. -

Q: Can ICs be made from materials other than silicon?

A: While silicon is the most common semiconductor material used for fabricating ICs, other materials like germanium, gallium arsenide, and silicon carbide are also used in specific applications. -

Q: What is the purpose of doping in semiconductors?

A: Doping is the process of introducing impurities into a semiconductor to modify its electrical properties. Doping creates n-type (electron-rich) and p-type (hole-rich) regions, which are essential for forming p-n junctions and controlling the flow of electrons in electronic devices. -

Q: How are ICs designed and manufactured?

A: ICs are designed using electronic design automation (EDA) tools, which help engineers create and simulate the circuit layout. The manufacturing process involves a series of steps, including photolithography, etching, doping, insulation, and metallization, to fabricate the IC on a semiconductor wafer. -

Q: What are the advantages of using larger wafer sizes in IC manufacturing?

A: Larger wafer sizes allow for more chips to be fabricated on a single wafer, reducing production costs and increasing throughput. However, transitioning to larger wafer sizes requires significant investments in new manufacturing equipment and facilities.

In conclusion, ICs, chips, semiconductors, and wafers are fundamental concepts in the world of electronics. Understanding their meanings, functions, and relationships is essential for anyone involved in electronic device design, manufacturing, or applications. As technology continues to advance, these components will play an increasingly crucial role in shaping the future of our digital world.

No responses yet