Introduction to BOM Components Purchase

A Bill of Materials (BOM) is a comprehensive list of raw materials, components, and instructions required to construct, manufacture, or repair a product or service. For electronics, the BOM includes all the parts needed to build a printed circuit board (PCB) or electronic assembly.

Purchasing components for a BOM involves carefully planning to ensure the right parts are procured in the proper quantities at the best prices and lead times. Key considerations include:

- Selecting reliable suppliers

- Verifying alternates and substitutions

- Order consolidation and bundling

- Lead time management

- Price negotiation

- Quality assurance

This guide provides an in-depth overview of the BOM component purchasing process to help optimize your procurement.

Table of Contents

- Understanding the BOM Structure

- Component Sourcing Strategies

- Evaluating Suppliers

- Optimizing Costs

- Ensuring Quality

- Managing Lead Times

- Handling Shortages and Obsolescence

- Leveraging Technology

- BOM Purchase FAQs

- Conclusion

Understanding the BOM Structure

The BOM serves as the foundation for the purchasing process. It’s a hierarchical document that defines the product structure, listing required components, and quantities. BOMs are typically divided into levels:

| BOM Level | Description |

|---|---|

| Top-level assembly | Final product |

| Sub-assemblies | Smaller assemblies that make up the final product |

| Components | Individual parts |

Each BOM level provides essential information for purchasing:

- Part numbers

- Descriptions

- Quantities

- Manufacturers

- Reference designators

Here’s an example of a simplified BOM structure:

| Level | Part Number | Description | Qty |

|---|---|---|---|

| 0 | 1000 | Final Product | 1 |

| 1 | 1100 | Main PCB Assembly | 1 |

| 2 | 1110 | PCB | 1 |

| 3 | 1111 | Resistor 10K | 10 |

| 3 | 1112 | Capacitor 100nF | 5 |

| 1 | 1200 | Power Supply | 1 |

| 2 | 1210 | AC/DC Converter | 1 |

Understanding the BOM hierarchy helps determine purchasing requirements, ensuring all necessary components are accounted for.

Component Sourcing Strategies

With the BOM in hand, the next step is developing a sourcing strategy. There are several approaches to consider:

Single vs. Multi-Sourcing

-

Single-sourcing involves purchasing a component from a single supplier. This can lead to volume discounts and stronger supplier relationships but also risks supply chain disruptions.

-

Multi-sourcing involves qualifying multiple suppliers for a component. This provides flexibility and reduces risk but may result in higher prices and increased management complexity.

The choice between single and multi-sourcing depends on factors such as:

- Component criticality

- Supplier reliability

- Budget constraints

- Risk tolerance

Approved Vendor List (AVL)

An AVL is a list of pre-qualified suppliers that meet specific criteria for quality, delivery, and price. Using an AVL streamlines the sourcing process and ensures consistency. However, it’s essential to regularly review and update the AVL to take advantage of new suppliers and pricing opportunities.

Alternate and Substitute Parts

Identifying alternate and substitute parts can help mitigate supply chain risks and optimize costs. Engineering should approve any alternates or substitutes to ensure compatibility and performance.

-

Alternate parts are components from different manufacturers that are functionally and mechanically equivalent to the original part.

-

Substitute parts are components that may have different specifications but can still be used in place of the original part with some modifications.

Evaluating Suppliers

Selecting the right suppliers is crucial for ensuring a reliable and cost-effective supply chain. Key factors to consider when evaluating suppliers include:

Quality

- ISO certifications

- Testing and inspection procedures

- Defect rates

- Warranty and return policies

Delivery

- On-time delivery performance

- Lead times

- Minimum order quantities (MOQs)

- Shipment tracking capabilities

Cost

- Competitive pricing

- Volume discounts

- Payment terms

- Shipping costs

Support

- Technical expertise

- Responsive communication

- Online ordering capabilities

- Inventory management services

Optimizing Costs

Effective BOM component purchasing involves balancing cost and quality. Some strategies for optimizing costs include:

Volume Discounts

Negotiating volume discounts can significantly reduce component costs. By committing to larger order quantities or long-term agreements, you may be able to secure better pricing.

Blanket Orders

Placing blanket orders involves committing to a total purchase quantity over a set period, with scheduled releases. This approach can lead to volume discounts and reduced administrative costs.

Economic Order Quantity (EOQ)

EOQ is a formula used to determine the optimal order quantity that minimizes total holding and ordering costs. The formula takes into account factors such as:

- Annual demand

- Order cost

- Holding cost

By calculating the EOQ, you can optimize order quantities and reduce overall costs.

Ensuring Quality

Maintaining component quality is essential for avoiding costly defects and rework. Some strategies for ensuring quality include:

Incoming Inspection

Performing incoming inspection on received components can help identify quality issues early in the process. This may involve visual inspection, functional testing, or laboratory analysis.

Supplier Audits

Conducting regular audits of supplier facilities and processes can help ensure consistent quality. Audits may include:

- Manufacturing process reviews

- Quality management system assessments

- Environmental and social responsibility checks

Traceability

Maintaining traceability throughout the supply chain can help identify the root cause of quality issues and facilitate recalls if necessary. This involves tracking components from the manufacturer to the end product using lot numbers, date codes, and serial numbers.

Managing Lead Times

Effective lead time management is crucial for avoiding production delays and stockouts. Some strategies for managing lead times include:

Supplier Communication

Regularly communicating with suppliers can help ensure on-time delivery. This may involve:

- Sharing forecast information

- Providing regular order updates

- Collaborating on inventory management

Safety Stock

Maintaining safety stock can help buffer against unexpected demand spikes or supply chain disruptions. Safety stock levels should be based on factors such as:

- Lead time variability

- Demand uncertainty

- Service level targets

Expediting

When necessary, expediting orders can help avoid production delays. This may involve:

- Paying for expedited shipping

- Negotiating with suppliers for faster production

- Sourcing from alternate suppliers

Handling Shortages and Obsolescence

Component shortages and obsolescence can significantly impact production schedules and costs. Some strategies for handling these issues include:

Proactive Monitoring

Regularly monitoring component availability and lifecycle status can help identify potential shortages or obsolescence risks early. This may involve:

- Subscribing to manufacturer product change notifications (PCNs)

- Monitoring industry news and trends

- Conducting regular BOM reviews

Last Time Buys

When a component is going end-of-life (EOL), placing a last time buy can help ensure a sufficient supply for future production. This involves purchasing enough components to cover expected demand until a replacement can be qualified.

Redesign and Substitution

In some cases, redesigning the product or substituting components may be necessary to address shortages or obsolescence. This requires close collaboration between engineering and purchasing to ensure any changes are compatible and cost-effective.

Leveraging Technology

Technology can help streamline and optimize the BOM component purchasing process. Some key technologies to consider include:

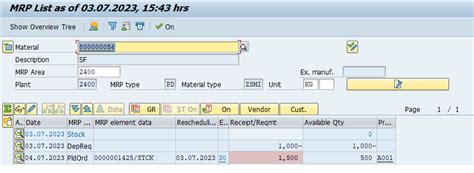

Enterprise Resource Planning (ERP)

ERP systems integrate various business functions, including purchasing, inventory management, and finance. This can help automate processes, improve visibility, and facilitate collaboration.

Supply Chain Management (SCM)

SCM software can help optimize supply chain operations, including demand planning, supplier management, and logistics. This can help reduce costs, improve efficiency, and mitigate risks.

E-Procurement

E-procurement platforms can help automate the purchasing process, from requisition to payment. This can help reduce administrative costs, improve compliance, and increase spend visibility.

BOM Purchase FAQs

1. What is the difference between a BOM and a parts list?

A BOM is a hierarchical document that defines the product structure, listing all required components, quantities, and assembly instructions. A parts list, on the other hand, is a simplified list of components without the hierarchical structure or assembly information.

2. How often should I review and update my BOM?

BOMs should be reviewed and updated regularly to ensure accuracy and take advantage of new components or pricing opportunities. The frequency of reviews depends on factors such as product lifecycle stage and market conditions but typically ranges from monthly to annually.

3. What should I do if a component becomes obsolete?

When a component becomes obsolete, there are several options:

- Place a last time buy to ensure a sufficient supply for future production

- Identify alternate or substitute components

- Redesign the product to use available components

The best approach depends on factors such as the component’s criticality, availability of alternates, and redesign costs.

4. How can I negotiate better prices with suppliers?

Some strategies for negotiating better prices with suppliers include:

- Leveraging volume discounts by committing to larger order quantities or long-term agreements

- Bundling multiple components or projects to increase purchasing power

- Conducting regular price benchmarking to ensure competitive pricing

- Exploring alternate suppliers or manufacturing locations

5. What are some common challenges in BOM component purchasing?

Some common challenges in BOM component purchasing include:

- Component shortages or obsolescence

- Long lead times

- Quality issues

- Price volatility

- Minimum order quantities (MOQs)

Effective strategies for addressing these challenges include proactive monitoring, strategic sourcing, supplier collaboration, and inventory management.

Conclusion

Effective BOM component purchasing is essential for ensuring a smooth and cost-effective manufacturing process. By understanding the BOM structure, developing a strategic sourcing approach, and leveraging technology, companies can optimize their purchasing operations and gain a competitive edge.

Key strategies for success include:

- Regularly reviewing and updating the BOM

- Evaluating and qualifying suppliers based on quality, delivery, cost, and support

- Optimizing costs through volume discounts, blanket orders, and economic order quantities

- Ensuring quality through incoming inspection, supplier audits, and traceability

- Managing lead times through supplier communication, safety stock, and expediting

- Handling shortages and obsolescence through proactive monitoring, last time buys, and redesign

By following the best practices outlined in this guide, companies can navigate the complexities of BOM component purchasing and build a resilient and efficient supply chain.

No responses yet