Introduction to Flexible PCBs and Their Growing Demand

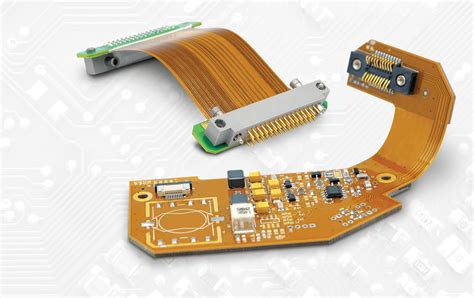

Flexible printed circuit boards (PCBs) have become increasingly popular in recent years due to their versatility, lightweight design, and ability to fit into compact spaces. These circuits are used in a wide range of applications, from consumer electronics to medical devices and aerospace systems. As the demand for flexible PCBs continues to grow, it’s essential for businesses to choose the right manufacturer to ensure high-quality products and reliable service.

In this article, we will conduct a comparative study of several leading flexible PCB manufacturers to help you make an informed decision when selecting a supplier for your project.

Key Factors to Consider When Choosing a Flexible PCB Manufacturer

Before diving into our comparison of flexible PCB manufacturers, let’s discuss the key factors you should consider when making your choice:

Quality and Reliability

The quality and reliability of your flexible PCBs are crucial to the success of your project. Look for manufacturers that adhere to strict quality control standards, such as ISO 9001 and IPC-6013, to ensure consistent and reliable products.

Manufacturing Capabilities

Different projects may require various manufacturing capabilities, such as multilayer boards, fine-pitch components, or high-density interconnects (HDI). Ensure that the manufacturer you choose has the necessary equipment and expertise to meet your specific requirements.

Lead Times and Delivery

In today’s fast-paced business environment, timely delivery is essential. Consider manufacturers with short lead times and a proven track record of meeting delivery deadlines.

Customer Support and Communication

Effective communication and responsive customer support can make a significant difference in the success of your project. Look for manufacturers that provide dedicated support teams, regular updates, and clear communication channels.

Cost and Value

While cost is an important consideration, it should not be the sole deciding factor. Focus on finding a manufacturer that offers the best value for your money, balancing quality, service, and price.

Comparative Analysis of Leading Flexible PCB Manufacturers

Now that we’ve established the key factors to consider, let’s compare some of the leading flexible PCB manufacturers in the industry.

Manufacturer A

Overview

Manufacturer A is a well-established company with over 20 years of experience in the PCB industry. They specialize in manufacturing flexible PCBs for a wide range of applications, including consumer electronics, medical devices, and automotive systems.

Manufacturing Capabilities

- Multilayer flexible PCBs (up to 12 layers)

- HDI technology

- Fine-pitch component assembly

- Rigid-flex PCBs

Quality and Certifications

- ISO 9001:2015 certified

- IPC-6013 Class 3 certified

- UL-certified materials

Lead Times and Delivery

Manufacturer A offers lead times as short as 5-7 days for prototypes and 2-3 weeks for production orders. They have a 98% on-time delivery rate.

Customer Support

Manufacturer A provides a dedicated account manager for each client, ensuring personalized support and regular communication throughout the project.

Manufacturer B

Overview

Manufacturer B is a newer player in the flexible PCB market, but they have quickly gained a reputation for their innovative solutions and competitive pricing. They focus on serving the consumer electronics and wearable technology sectors.

Manufacturing Capabilities

- Single and double-sided flexible PCBs

- Multilayer boards (up to 8 layers)

- Flexible printed circuits with SMT assembly

- Flexible-rigid PCBs

Quality and Certifications

- ISO 9001:2015 certified

- IPC-6013 Class 2 certified

Lead Times and Delivery

Manufacturer B offers lead times of 7-10 days for prototypes and 3-4 weeks for production orders. They have a 95% on-time delivery rate.

Customer Support

Manufacturer B provides a responsive customer support team, but they do not assign dedicated account managers to each client.

Manufacturer C

Overview

Manufacturer C is a global company with facilities in multiple countries, allowing them to serve a diverse range of customers. They have extensive experience in manufacturing flexible PCBs for the medical, aerospace, and defense industries.

Manufacturing Capabilities

- Single and double-sided flexible PCBs

- Multilayer boards (up to 16 layers)

- HDI technology

- Flex-rigid PCBs

- Flexible circuits with embedded components

Quality and Certifications

- ISO 9001:2015 certified

- ISO 13485:2016 certified (medical devices)

- AS9100D certified (aerospace)

- IPC-6013 Class 3 certified

- ITAR compliant

Lead Times and Delivery

Manufacturer C offers lead times of 10-14 days for prototypes and 4-6 weeks for production orders. They have a 99% on-time delivery rate.

Customer Support

Manufacturer C provides a global network of support teams, with dedicated account managers for large projects. They also offer design support and engineering services.

Comparison Table

| Manufacturer | Manufacturing Capabilities | Quality Certifications | Lead Times (Prototype / Production) | On-Time Delivery Rate | Customer Support |

|---|---|---|---|---|---|

| A | Multilayer (up to 12), HDI, Fine-pitch, Rigid-flex | ISO 9001, IPC-6013 Class 3, UL | 5-7 days / 2-3 weeks | 98% | Dedicated account manager |

| B | Single & double-sided, Multilayer (up to 8), SMT assembly, Flex-rigid | ISO 9001, IPC-6013 Class 2 | 7-10 days / 3-4 weeks | 95% | Responsive team, no dedicated manager |

| C | Single & double-sided, Multilayer (up to 16), HDI, Flex-rigid, Embedded components | ISO 9001, ISO 13485, AS9100D, IPC-6013 Class 3, ITAR | 10-14 days / 4-6 weeks | 99% | Global support, dedicated managers for large projects |

Frequently Asked Questions (FAQ)

-

Q: How do I choose the right flexible PCB manufacturer for my project?

A: Consider factors such as manufacturing capabilities, quality certifications, lead times, delivery reliability, customer support, and cost. Evaluate your project requirements and prioritize the factors that are most important to you. -

Q: What are the advantages of using flexible PCBs over rigid PCBs?

A: Flexible PCBs offer several advantages, including lighter weight, increased durability, better resistance to vibration and shock, and the ability to fit into compact or irregular spaces. They also allow for greater design flexibility and can reduce the overall size of electronic devices. -

Q: Can flexible PCB manufacturers help with the design process?

A: Many flexible PCB manufacturers offer design support and engineering services to help optimize your PCB layout and ensure manufacturability. Some manufacturers, like Manufacturer C, have dedicated teams to assist with design challenges. -

Q: What is the typical lead time for flexible PCB production?

A: Lead times can vary depending on the manufacturer and the complexity of your project. Generally, prototype lead times range from 5 to 14 days, while production lead times can be anywhere from 2 to 6 weeks. -

Q: How can I ensure the quality and reliability of my flexible PCBs?

A: Choose a manufacturer with strict quality control standards and relevant certifications, such as ISO 9001, IPC-6013, and industry-specific certifications like ISO 13485 for medical devices or AS9100D for aerospace. Additionally, maintain open communication with your manufacturer and establish clear quality expectations from the outset of your project.

Conclusion

Selecting the right flexible PCB manufacturer is crucial to the success of your project. By considering factors such as manufacturing capabilities, quality, lead times, customer support, and cost, you can make an informed decision that best suits your needs.

In our comparative study, we evaluated three leading flexible PCB manufacturers. Manufacturer A excels in multilayer and HDI capabilities, while Manufacturer B offers competitive pricing and a focus on consumer electronics. Manufacturer C stands out for its global presence, extensive certifications, and experience in the medical and aerospace industries.

Ultimately, the best manufacturer for your project will depend on your specific requirements and priorities. Use the information provided in this article as a starting point for your research, and don’t hesitate to reach out to manufacturers directly to discuss your project in more detail.

By partnering with the right flexible PCB manufacturer, you can ensure high-quality, reliable products that meet your performance and timeline expectations.

No responses yet