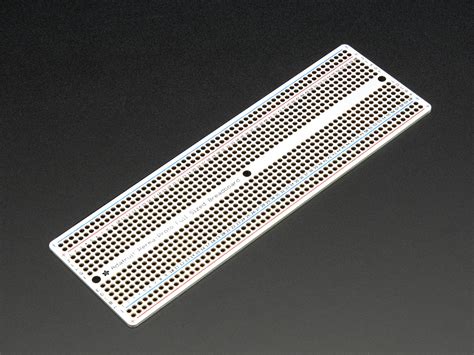

What is a Breadboard?

A breadboard is a reusable prototyping board used for building and testing electronic circuits without the need for soldering. It consists of a plastic board with a grid of holes, into which electronic components and jumper wires can be inserted. The holes are internally connected in a specific pattern, allowing for the creation of electrical connections between components.

Advantages of Breadboards

-

Reusability: Breadboards are designed for temporary prototyping, allowing you to easily insert and remove components without damaging them. This makes it convenient to experiment with different circuit designs and make modifications as needed.

-

Solderless: Breadboards do not require any soldering, making them accessible to beginners and those who are not proficient in soldering techniques. Components can be simply inserted into the holes, and connections are made through the internal connections of the breadboard.

-

Quick prototyping: With a breadboard, you can quickly assemble a circuit and test its functionality. It is an ideal tool for rapid prototyping and experimenting with different circuit configurations.

-

Educational value: Breadboards are widely used in educational settings to teach electronics and circuit design. They provide a hands-on learning experience and allow students to visualize the connections between components.

Disadvantages of Breadboards

-

Limited current capacity: Breadboards have a limited current carrying capacity due to the thin metal strips used for internal connections. They are not suitable for high-current applications or power-hungry circuits.

-

Prone to loose connections: The mechanical connections in a breadboard can become loose over time, especially with frequent use. This can lead to intermittent connections and unreliable circuit behavior.

-

Not suitable for permanent installations: Breadboards are designed for temporary prototyping and are not recommended for permanent installations or final products. They lack the robustness and reliability required for long-term use.

-

Limited size: Breadboards come in various sizes, but they have limitations on the number of components and the complexity of the circuit that can be accommodated. Complex circuits may require multiple breadboards or a different prototyping solution.

What is a PCB?

A printed circuit board (PCB) is a custom-designed board that provides a permanent and reliable platform for electronic components. It consists of a non-conductive substrate, typically made of fiberglass or other materials, with conductive copper traces etched onto its surface. Components are soldered onto the PCB, creating a robust and durable circuit.

Advantages of PCBs

-

Reliability: PCBs offer a high level of reliability compared to breadboards. The soldered connections provide a secure and stable electrical contact, reducing the chances of loose connections or intermittent behavior.

-

Compact and space-efficient: PCBs allow for the miniaturization of electronic circuits. Components can be placed close together, and the copper traces can be designed to optimize space utilization, resulting in compact and efficient layouts.

-

Customizable: PCBs can be custom-designed to meet specific requirements and specifications. The layout, size, shape, and number of layers can be tailored to suit the needs of the project, enabling the creation of application-specific circuits.

-

Mass production: Once a PCB design is finalized, it can be easily replicated and mass-produced. This is particularly advantageous for commercial products or large-scale projects where multiple identical boards are required.

-

Improved signal integrity: PCBs offer better signal integrity compared to breadboards. The copper traces are designed to minimize noise, crosstalk, and electromagnetic interference (EMI), ensuring cleaner and more reliable signal transmission.

Disadvantages of PCBs

-

Higher cost: Designing and manufacturing PCBs is generally more expensive than using breadboards. The cost includes the PCB fabrication, component sourcing, and assembly, which can be significant for low-volume production or one-off projects.

-

Longer development time: Creating a PCB involves a design phase, fabrication, and assembly process, which can take longer compared to prototyping on a breadboard. Any design changes or modifications require a new PCB iteration, adding to the development time.

-

Requires soldering skills: Assembling components onto a PCB requires soldering skills. While soldering is a valuable skill to have, it may be a barrier for beginners or those who are not comfortable with soldering techniques.

-

Limited flexibility for modifications: Once a PCB is fabricated and assembled, making modifications or changes to the circuit can be challenging. It often requires desoldering components, cutting traces, or using jumper wires, which can be time-consuming and potentially damage the board.

When to Use a Breadboard

Breadboards are ideal in the following scenarios:

-

Rapid prototyping: When you want to quickly test a circuit idea or experiment with different configurations, a breadboard allows for fast and easy prototyping without the need for soldering.

-

Educational purposes: Breadboards are widely used in educational settings to teach electronics and circuit design. They provide a hands-on learning experience and allow students to visualize the connections between components.

-

Temporary setups: If you need a temporary setup for a demonstration, testing, or short-term use, a breadboard is a convenient option. It allows for quick assembly and disassembly of the circuit.

-

Low-complexity circuits: For simple circuits with a limited number of components and connections, a breadboard can be sufficient. It is suitable for basic projects and proof-of-concept demonstrations.

When to Use a PCB

PCBs are preferred in the following situations:

-

Final product development: When you are ready to move from the prototyping stage to the final product, a PCB provides a reliable and robust platform for your circuit. It ensures the circuit’s integrity and long-term performance.

-

Mass production: If you plan to manufacture multiple identical boards or produce a commercial product, PCBs are the way to go. They can be easily replicated and mass-produced, ensuring consistency and reducing per-unit costs.

-

High-reliability applications: For projects that require high reliability, such as industrial or aerospace applications, PCBs offer a more secure and stable solution. The soldered connections and customized layout provide better signal integrity and minimize the risk of failures.

-

Space-constrained designs: When space is limited, PCBs allow for compact and efficient layouts. Components can be placed close together, and the traces can be optimized to minimize the board size, making PCBs suitable for small form factor devices.

-

High-frequency or sensitive circuits: For circuits operating at high frequencies or dealing with sensitive signals, PCBs provide better signal integrity and noise reduction compared to breadboards. The controlled impedance and shielding offered by PCBs are essential for such applications.

Breadboard vs PCB Comparison Table

| Aspect | Breadboard | PCB |

|---|---|---|

| Reusability | Reusable for prototyping | Permanent, not reusable |

| Soldering | Solderless, components are inserted | Requires soldering of components |

| Prototyping Speed | Fast and easy for quick prototyping | Slower, involves design and fabrication process |

| Reliability | Prone to loose connections and intermittent issues | High reliability with soldered connections |

| Current Capacity | Limited current carrying capacity | Higher current capacity, customizable |

| Customization | Limited customization options | Highly customizable layout and design |

| Size and Compactness | Limited by breadboard size and component spacing | Compact and space-efficient layouts possible |

| Mass Production | Not suitable for mass production | Ideal for mass production and replication |

| Signal Integrity | Susceptible to noise and interference | Better signal integrity and noise reduction |

| Cost | Low cost for prototyping | Higher cost for design, fabrication, and assembly |

FAQ

-

Q: Can I use a breadboard for a permanent installation?

A: No, breadboards are designed for temporary prototyping and are not recommended for permanent installations. They lack the robustness and reliability required for long-term use. For permanent installations, it is advisable to use a PCB. -

Q: Is it possible to convert a breadboard circuit to a PCB?

A: Yes, it is possible to convert a breadboard circuit to a PCB. Once you have tested and finalized your circuit on a breadboard, you can design a PCB layout based on the breadboard connections. The PCB design can then be sent for fabrication and assembled with the components. -

Q: Can I use a PCB for prototyping?

A: While PCBs are primarily used for final product development and mass production, it is possible to use them for prototyping as well. However, the process of designing, fabricating, and assembling a PCB is more time-consuming and costly compared to using a breadboard. PCB Prototyping is more suitable when you have a finalized circuit design and want to test it in a more permanent and reliable form. -

Q: Are there any alternatives to breadboards for prototyping?

A: Yes, there are several alternatives to breadboards for prototyping. Some options include: - Prototype PCBs: These are simplified PCBs designed for quick prototyping. They often have pre-defined layouts and can be easily customized.

- Stripboards: Also known as veroboards, these are boards with pre-drilled holes and copper strips for soldering components.

-

Perfboards: These are blank boards with pre-drilled holes, allowing for custom layouts and connections using jumper wires.

-

Q: Can I mix and match components between breadboards and PCBs?

A: Yes, you can use the same components on both breadboards and PCBs. However, keep in mind that some components may have different package types or sizes suitable for each platform. When transitioning from a breadboard to a PCB, ensure that the components are compatible with the PCB design and can be properly soldered.

Conclusion

Breadboards and PCBs are both essential tools in electronic circuit development, each serving a distinct purpose. Breadboards offer a quick and easy way to prototype and experiment with circuit ideas, while PCBs provide a reliable and permanent solution for final product development and mass production.

When deciding between a breadboard and a PCB, consider factors such as the stage of your project, the complexity of the circuit, the desired reliability, and the production scale. Breadboards are ideal for rapid prototyping, educational purposes, and temporary setups, while PCBs are preferred for final product development, mass production, and high-reliability applications.

By understanding the differences between breadboards and PCBs, you can make informed decisions and choose the appropriate tool for your electronic projects. Whether you are a beginner learning the basics of electronics or an experienced engineer working on complex designs, having a clear understanding of when to use a breadboard or a PCB will help you efficiently develop and bring your electronic ideas to life.

No responses yet