What is FR4 composite material?

Composition of FR4 composite FR4 composite consists of two main components: Glass fabric reinforcement Epoxy resin matrix The glass fabric is typically made from electrical-grade[…]

What type of material is FR4?

Composition of FR4 PCB substrate The FR in FR4 stands for “Flame Retardant”, while the 4 refers to woven glass reinforced epoxy resin. The primary[…]

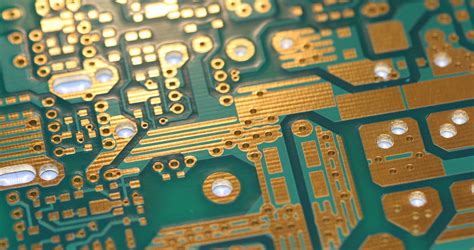

What material is most commonly used to form the traces on PCBs?

What are PCB traces? PCB traces are the thin lines of copper that form the conductive pathways on a printed circuit board. Traces carry electrical[…]

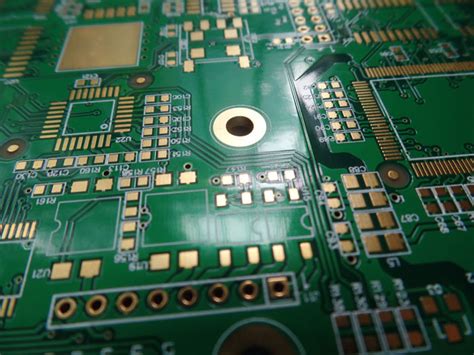

What is FR4 commonly used in?

Introduction to FR4 FR4 (Flame Retardant 4) is a versatile and widely used material in the electronics industry, particularly in the production of printed circuit[…]

What is the most commonly used PCB material?

Types of PCB materials PCB Materials can be broadly categorized into two main types: Rigid PCB materials Flexible PCB materials Rigid PCB Materials Rigid PCB[…]

Is FR4 a good insulator?

What is FR4? FR4 is a type of laminate material that consists of multiple layers of woven fiberglass cloth impregnated with an epoxy resin. The[…]

What is the quality of FR4?

What is FR4? FR4 is a composite material made from woven fiberglass cloth impregnated with an epoxy resin binder. The “FR” in FR4 stands for[…]

Is FR4 durability?

What is FR4? FR4 is a composite material made from woven fiberglass cloth and an epoxy resin binder. The “FR” stands for “Flame Retardant,” and[…]

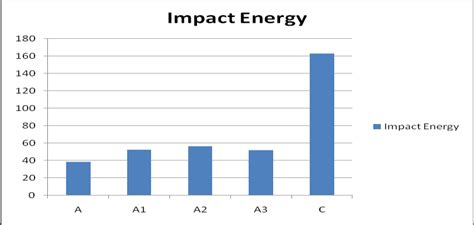

What is the impact strength of FR4?

Understanding Impact Strength Impact strength is a measure of a material’s ability to absorb energy during a sudden, high-speed impact without fracturing. It is an[…]

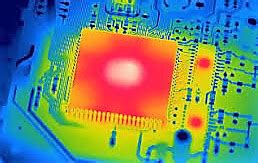

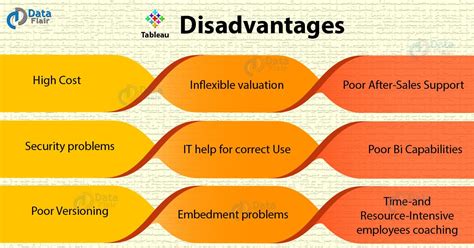

What are the disadvantages of FR4?

Keyword: FR4 Disadvantages High Dielectric Constant and Dissipation Factor One of the main disadvantages of FR4 is its relatively high dielectric constant (Dk) and dissipation[…]