Introduction

Printed Circuit Boards (PCBs) are essential components in modern electronics, forming the backbone of countless devices we use daily. When designing and manufacturing electronic products, one of the most important considerations is the cost of PCB production. In this article, we will explore the factors that influence PCB cost and provide insights into whether PCBs are expensive to make.

What is a PCB?

A Printed Circuit Board (PCB) is a flat board made of insulating material, such as fiberglass or epoxy resin, with conductive copper traces etched onto its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to create a functional electronic circuit. PCBs are used in a wide range of applications, from simple consumer electronics to complex industrial equipment and aerospace systems.

Factors Affecting PCB Cost

The cost of manufacturing a PCB depends on several factors, including:

-

Board Size: Larger PCBs require more materials and take longer to manufacture, resulting in higher costs.

-

Number of Layers: PCBs can have single or multiple layers. As the number of layers increases, so does the manufacturing complexity and cost.

-

Material Type: The choice of PCB material, such as FR-4, high-frequency laminates, or flexible substrates, affects the overall cost.

-

Quantity: Higher production volumes generally lead to lower per-unit costs due to economies of scale.

-

Component Density: Boards with a higher density of components require more precise manufacturing processes, which can increase costs.

-

Surface Finish: Different surface finishes, such as Hot Air Solder Leveling (HASL), Immersion Silver, or Gold Plating, have varying costs.

-

Turnaround Time: Faster turnaround times often come with a premium price tag.

PCB Manufacturing Process and Associated Costs

The PCB manufacturing process involves several steps, each contributing to the overall cost:

-

Design and Engineering: Creating the PCB layout and schematic, which may involve using specialized software and engineering expertise.

-

Prototyping: Producing a small number of boards for testing and validation before mass production.

-

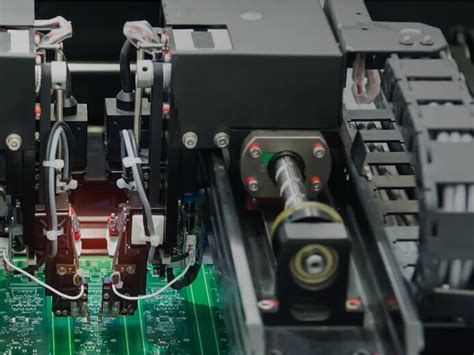

Fabrication: The actual manufacturing of the PCB, including etching, drilling, and lamination.

-

Assembly: Placing and soldering components onto the PCB.

-

Testing and Quality Control: Ensuring the PCB functions as intended and meets quality standards.

PCB Fabrication Costs

The fabrication cost is a significant portion of the total PCB cost. It depends on factors such as the board size, number of layers, and the type of materials used. The table below provides a rough estimate of PCB fabrication costs based on the number of layers and board size:

| Number of Layers | Board Size (sq. in.) | Cost per sq. in. |

|---|---|---|

| 1 – 2 | < 10 | $0.50 – $1.50 |

| 1 – 2 | 10 – 50 | $0.25 – $0.75 |

| 4 – 6 | < 10 | $1.00 – $2.50 |

| 4 – 6 | 10 – 50 | $0.50 – $1.50 |

| 8+ | < 10 | $2.00 – $4.00 |

| 8+ | 10 – 50 | $1.00 – $2.50 |

Note: These prices are rough estimates and may vary depending on the manufacturer and specific requirements.

PCB Assembly Costs

Assembly costs depend on factors such as the number and type of components, the complexity of the assembly process, and the level of automation used. Some key considerations include:

-

Component Costs: The cost of individual components can vary widely, from a few cents for passive components to several dollars for complex ICs.

-

Assembly Method: Manual assembly is more labor-intensive and expensive, while automated assembly using pick-and-place machines is faster and more cost-effective for high volumes.

-

Soldering Technique: Wave soldering, reflow soldering, and selective soldering have different costs and are suited for different types of components and board designs.

Strategies for Reducing PCB Costs

There are several strategies that can help reduce PCB costs without compromising quality:

-

Design Optimization: Simplifying the PCB design, minimizing the number of layers, and using standard components can help reduce manufacturing costs.

-

Cost-Effective Material Selection: Choosing appropriate materials based on the application requirements and cost constraints.

-

Volume Pricing: Ordering larger quantities of PCBs can lead to significant cost savings due to economies of scale.

-

Offshore Manufacturing: Outsourcing PCB manufacturing to countries with lower labor costs, such as China or India, can reduce expenses. However, it’s essential to consider factors like quality control, intellectual property protection, and logistics.

-

Panelization: Combining multiple PCB designs into a single panel can reduce fabrication costs by optimizing material usage and minimizing setup times.

Are PCBs Expensive to Make?

The answer to whether PCBs are expensive to make depends on various factors and the specific requirements of the project. While PCB manufacturing involves significant costs, there are ways to optimize designs and manufacturing processes to reduce expenses. In general, higher-complexity boards, smaller quantities, and faster turnaround times will result in higher costs.

However, it’s essential to consider the total cost of ownership (TCO) when evaluating PCB costs. The initial manufacturing cost is just one aspect; factors like reliability, performance, and long-term maintenance should also be taken into account. Investing in high-quality PCBs can lead to better product performance, reduced failure rates, and lower overall system costs in the long run.

Frequently Asked Questions (FAQ)

-

What is the average cost of a simple, single-layer PCB?

A simple, single-layer PCB can cost anywhere from $0.50 to $1.50 per square inch, depending on the board size and quantity ordered. -

How much do components add to the total cost of a PCB?

Component costs can vary widely depending on the type and quantity required. Passive components like resistors and capacitors are relatively inexpensive, while complex ICs can cost several dollars each. The total component cost can easily exceed the PCB fabrication cost for boards with a high component count. -

Is it cheaper to manufacture PCBs in China?

Manufacturing PCBs in China or other countries with lower labor costs can often result in lower overall costs. However, it’s essential to consider factors like shipping, tariffs, quality control, and intellectual property protection when deciding to outsource manufacturing. -

What is the most expensive part of PCB manufacturing?

The most expensive part of PCB manufacturing can vary depending on the specific project requirements. For complex, high-layer count boards, the fabrication cost may dominate, while for boards with numerous expensive components, the assembly cost may be the most significant factor. -

How can I reduce the cost of my PCB project?

To reduce PCB costs, consider optimizing your design for manufacturability, selecting cost-effective materials, leveraging volume pricing, and exploring offshore manufacturing options. Collaborating closely with your PCB manufacturer and assembly partner can also help identify cost-saving opportunities.

Conclusion

In conclusion, the cost of manufacturing PCBs depends on a wide range of factors, from board size and complexity to material choice and production volume. While PCBs can be expensive to make, careful design optimization, strategic material selection, and leveraging economies of scale can help reduce costs. It’s essential to consider the total cost of ownership and balance initial manufacturing costs with long-term performance, reliability, and maintenance requirements.

As technology continues to advance and demand for electronic devices grows, efficient and cost-effective PCB manufacturing will remain a critical priority for businesses and engineers alike. By understanding the factors that influence PCB cost and implementing smart design and manufacturing strategies, it’s possible to create high-quality, reliable PCBs that meet both performance and budget requirements.

No responses yet