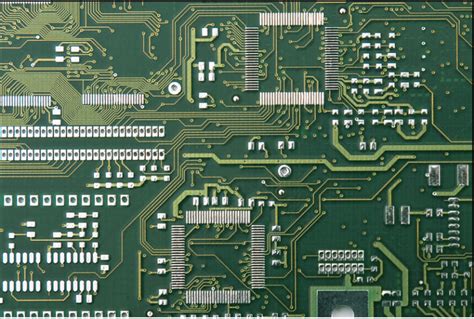

What are Multilayer PCBs?

Multilayer PCBs are circuit boards that consist of three or more conductive copper layers separated by insulating layers. These layers are stacked and laminated together to form a single board, allowing for more complex circuits and higher component density compared to single or double-layer PCBs.

Structure of Multilayer PCBs

A typical multilayer PCB consists of the following layers:

-

Copper layers: These are the conductive layers that carry electrical signals between components. The number of copper layers can vary depending on the complexity of the circuit, with some multilayer PCBs having up to 50 layers or more.

-

Insulating layers: These layers, often made of FR-4 (a glass-reinforced epoxy laminate), separate the copper layers and provide electrical insulation. They also help to maintain the structural integrity of the board.

-

Prepreg layers: Prepreg (pre-impregnated) layers are thin sheets of glass fabric that have been impregnated with a partially cured resin. These layers are placed between the copper and insulating layers to bond them together during the lamination process.

-

Solder mask: A solder mask is a thin layer of polymer applied to the outer surfaces of the PCB. It protects the copper traces from oxidation and prevents solder bridges from forming between adjacent pads during the soldering process.

-

Silkscreen: The silkscreen layer is used to print text, logos, and component identifiers on the surface of the PCB, making it easier to assemble and troubleshoot the board.

Advantages of Multilayer PCBs

Multilayer PCBs offer several advantages over single or double-layer boards:

-

Increased circuit density: By utilizing multiple layers, designers can create more complex circuits in a smaller footprint, enabling the development of compact and high-performance devices.

-

Improved signal integrity: Multilayer PCBs allow for the use of dedicated power and ground planes, which help to reduce electromagnetic interference (EMI) and improve signal quality.

-

Enhanced thermal management: The increased number of layers in a multilayer PCB helps to dissipate heat more effectively, preventing components from overheating and improving overall system reliability.

-

Reduced crosstalk: By carefully arranging signal traces and using proper shielding techniques, designers can minimize crosstalk between adjacent signals, ensuring reliable communication within the circuit.

-

Cost-effective for high-volume production: Although the initial design and setup costs for multilayer PCBs may be higher than single or double-layer boards, they become more cost-effective when produced in large quantities due to their increased functionality and smaller size.

Manufacturing Process

The manufacturing process for multilayer PCBs is more complex than that of single or double-layer boards, involving several key steps:

-

Design and layout: The circuit is designed using electronic design automation (EDA) software, which generates the necessary files for manufacturing, including Gerber files and drill files.

-

Inner layer fabrication: The inner copper layers are etched using a photolithographic process, which involves applying a light-sensitive resist to the copper, exposing it to UV light through a photomask, and then developing and etching the unwanted copper away.

-

Lamination: The etched inner layers are stacked with prepreg and insulating layers, then subjected to high pressure and heat in a lamination press. This process bonds the layers together to form a solid board.

-

Drilling: Holes are drilled through the laminated board to accommodate Through-hole components and create vias that connect the different layers.

-

Plating: The drilled holes are plated with copper to create electrical connections between layers.

-

Outer layer fabrication: The outer layers are etched using the same photolithographic process used for the inner layers.

-

Solder mask and silkscreen application: The solder mask and silkscreen layers are applied to the outer surfaces of the board.

-

Surface finish: A surface finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the exposed copper pads to prevent oxidation and improve solderability.

-

Electrical testing: The completed board undergoes electrical testing to ensure that all connections are functioning correctly and that there are no short circuits or open connections.

Applications of Multilayer PCBs

Multilayer PCBs are used in a wide range of industries and applications, including:

- Consumer electronics: Smartphones, tablets, laptops, and wearables.

- Automotive: Engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

- Medical devices: Implantable devices, diagnostic equipment, and patient monitoring systems.

- Aerospace and defense: Avionics, radar systems, and satellite communication equipment.

- Industrial automation: Programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial robots.

Design Considerations for Multilayer PCBs

Designing multilayer PCBs requires careful consideration of several factors to ensure optimal performance and manufacturability:

-

Layer stackup: Determining the appropriate number of layers and their arrangement is crucial for achieving the desired electrical performance and manufacturing feasibility.

-

Signal integrity: Proper trace routing, impedance control, and shielding techniques must be employed to maintain signal integrity and minimize crosstalk and EMI.

-

Thermal management: Adequate thermal relief and the use of thermal vias can help to dissipate heat and prevent components from overheating.

-

Manufacturability: Designers must adhere to manufacturing constraints, such as minimum trace widths, spacing, and drill sizes, to ensure that the board can be reliably produced.

-

Cost: Balancing the number of layers, materials, and features with the target cost is essential for creating a cost-effective solution.

Future Trends in Multilayer PCBs

As technology continues to advance, multilayer PCBs are evolving to meet the growing demands of modern electronics:

-

High-speed designs: With the increasing prevalence of high-speed interfaces like PCIe, USB, and HDMI, multilayer PCBs are being optimized for high-speed signal transmission through the use of advanced materials and design techniques.

-

Embedded components: To further increase density and functionality, some multilayer PCBs are incorporating embedded components, such as capacitors and resistors, within the layers of the board.

-

Flexible and Rigid-Flex PCBs: The use of flexible and rigid-flex multilayer PCBs is growing, particularly in wearable devices and aerospace applications where flexibility and reliability are critical.

-

Advanced materials: New materials, such as low-loss dielectrics and high-temperature laminates, are being developed to improve the performance and reliability of multilayer PCBs in demanding environments.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a multilayer PCB and a single or double-layer PCB?

A: Multilayer PCBs have three or more conductive layers, while Single-Layer PCBs have one conductive layer and double-layer PCBs have two. Multilayer PCBs offer higher density, improved signal integrity, and better thermal management compared to single or double-layer boards. -

Q: How many layers can a multilayer PCB have?

A: The number of layers in a multilayer PCB can vary depending on the complexity of the circuit and the application. Some boards may have as few as four layers, while others can have 50 or more layers. -

Q: Are multilayer PCBs more expensive than single or double-layer PCBs?

A: Yes, multilayer PCBs are generally more expensive than single or double-layer boards due to the increased complexity of the manufacturing process and the cost of additional materials. However, they become more cost-effective when produced in large quantities and offer more functionality in a smaller footprint. -

Q: What industries commonly use multilayer PCBs?

A: Multilayer PCBs are used in a wide range of industries, including consumer electronics, automotive, medical devices, aerospace and defense, and industrial automation. -

Q: What are some key design considerations for multilayer PCBs?

A: When designing multilayer PCBs, engineers must consider factors such as layer stackup, signal integrity, thermal management, manufacturability, and cost to ensure optimal performance and reliability.

Conclusion

Multilayer PCBs have revolutionized the electronics industry by enabling the development of compact, high-performance devices with complex circuitry. By understanding the structure, manufacturing process, advantages, and applications of multilayer PCBs, engineers can design and produce boards that meet the growing demands of modern technology. As new materials and techniques continue to emerge, the future of multilayer PCBs looks bright, with exciting possibilities for even more advanced and innovative electronic devices.

No responses yet