Introduction to PCB Layout

Printed Circuit Board (PCB) layout is a crucial step in the design and manufacturing of electronic devices. It involves the arrangement of components and the routing of traces on a PCB to ensure optimal performance, reliability, and manufacturability. In this comprehensive guide, we will explore the best practices and techniques for placing components on a PCB, with a focus on the services provided by RAYPCB, a leading PCB manufacturing company.

The Importance of Proper Component Placement

Proper component placement is essential for several reasons:

-

Signal Integrity: The placement of components can significantly impact the signal integrity of a PCB. By minimizing the distance between related components and reducing the length of traces, you can minimize signal reflections, crosstalk, and other issues that can degrade signal quality.

-

Thermal Management: The placement of components can also affect the thermal performance of a PCB. By strategically placing heat-generating components and providing adequate spacing between them, you can ensure effective heat dissipation and prevent thermal issues.

-

Manufacturing Feasibility: The placement of components must also consider the manufacturing process. Proper spacing between components, alignment with the PCB edges, and consideration of assembly techniques can help ensure a smooth and efficient manufacturing process.

RAYPCB’s Expertise in PCB Layout

RAYPCB is a leading provider of PCB manufacturing services, offering a wide range of solutions for various industries. With years of experience and a team of skilled engineers, RAYPCB has developed a deep understanding of the best practices for PCB layout. By partnering with RAYPCB, you can leverage their expertise to optimize your PCB design and ensure the best possible performance and manufacturability.

PCB Layout Guidelines

To achieve optimal results, follow these guidelines when placing components on your PCB:

Component Orientation

- Place components in a logical and organized manner, grouping related components together.

- Orient components in a way that minimizes the length of traces and reduces the number of vias required.

- Consider the direction of signal flow and place components accordingly.

Placement Techniques

- Use a grid-based placement approach to ensure consistent spacing and alignment of components.

- Place larger components first, followed by smaller components, to optimize space utilization.

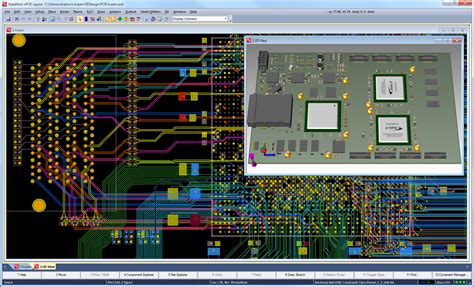

- Use CAD tools with automatic placement features to speed up the process and ensure compliance with design rules.

Thermal Considerations

- Identify heat-generating components and place them strategically to ensure effective heat dissipation.

- Provide adequate spacing between heat-generating components to prevent thermal interaction.

- Use thermal vias and heat sinks when necessary to enhance heat dissipation.

Signal Integrity Considerations

- Place sensitive components, such as high-speed devices, away from sources of electromagnetic interference (EMI).

- Use ground planes and power planes to provide a low-impedance return path for signals.

- Route high-speed signals on inner layers to minimize EMI and crosstalk.

Manufacturability Considerations

- Ensure adequate spacing between components to facilitate soldering and assembly.

- Align components with the edges of the PCB to simplify the panelization process.

- Consider the placement of test points and fiducial markers to aid in the manufacturing and testing process.

Component Placement Techniques

Grouping Related Components

One of the key techniques in PCB layout is grouping related components together. This approach offers several benefits:

-

Shorter Traces: By placing related components in close proximity, you can minimize the length of traces required to connect them. Shorter traces reduce signal reflections, improve signal integrity, and minimize EMI.

-

Easier Routing: Grouping related components together simplifies the routing process. It allows for more direct and efficient routing of traces, reducing the complexity of the PCB layout.

-

Improved Functionality: Placing related components together can also enhance the functionality of the circuit. For example, placing decoupling capacitors close to the power pins of ICs can effectively suppress power supply noise and improve overall performance.

Placement Examples

To illustrate the concept of grouping related components, let’s consider a few examples:

- Power Supply Section:

- Place the power input connector, voltage regulators, and associated capacitors in close proximity.

-

Minimize the distance between the voltage regulators and the power planes to reduce impedance and improve power distribution.

-

Analog and Digital Sections:

- Separate analog and digital components to minimize noise coupling between the two domains.

-

Place analog components away from high-speed digital components and power supply circuitry.

-

High-Speed Components:

- Place high-speed components, such as microprocessors, FPGAs, and memory devices, in close proximity to minimize trace lengths and improve signal integrity.

- Provide adequate spacing between high-speed components to minimize crosstalk and EMI.

Using CAD Tools for Component Placement

Modern CAD tools offer powerful features to assist in component placement. These tools can help you optimize your PCB layout by providing automated placement options, design rule checks (DRC), and real-time feedback on potential issues. Some of the key features to look for in a CAD tool for component placement include:

-

Automatic Placement: Automated placement algorithms can quickly arrange components based on predefined rules and constraints, saving time and effort in the layout process.

-

Design Rule Checks: DRC tools can analyze your PCB layout and identify potential issues, such as component spacing violations, trace width violations, and clearance issues.

-

Real-Time Feedback: Some CAD tools provide real-time feedback on the placement of components, highlighting potential problems and suggesting improvements.

RAYPCB’s team of experienced engineers can provide guidance and support in selecting the right CAD tools and utilizing their features effectively for optimized component placement.

Advanced PCB Layout Techniques

Multilayer PCB Design

For more complex designs, multilayer PCBs offer several advantages over single-layer boards. Multilayer PCBs allow for higher component density, improved signal integrity, and better power distribution. When designing a multilayer PCB, consider the following:

-

Layer Stack-up: Determine the number of layers required and the arrangement of signal, power, and ground layers. RAYPCB can provide guidance on optimal layer stack-ups for your specific design requirements.

-

Signal Routing: Route high-speed signals on inner layers to minimize EMI and crosstalk. Use via shielding and ground planes to provide a low-impedance return path for signals.

-

Power Distribution: Use dedicated power planes to provide a low-impedance power distribution network. Place decoupling capacitors close to the power pins of ICs to suppress power supply noise.

High-Speed PCB Design

Designing PCBs for high-speed applications requires special considerations to ensure signal integrity and minimize EMI. Some key techniques for high-speed PCB design include:

-

Impedance Control: Use controlled impedance traces to match the impedance of the source and load, minimizing signal reflections and ensuring proper signal termination.

-

Differential Signaling: Use differential signaling for high-speed data transmission to minimize EMI and improve signal integrity.

-

Length Matching: Match the lengths of related traces, such as clock and data lines, to ensure proper timing and minimize signal skew.

RAYPCB has extensive experience in high-speed PCB design and can provide guidance and support in implementing these techniques effectively.

Frequently Asked Questions (FAQ)

-

Q: What is the importance of component placement in PCB layout?

A: Component placement is crucial for ensuring optimal performance, reliability, and manufacturability of a PCB. Proper placement can minimize signal integrity issues, improve thermal management, and facilitate efficient manufacturing processes. -

Q: How can I ensure proper spacing between components?

A: Use a grid-based placement approach and follow the recommended spacing guidelines provided by component manufacturers and PCB design standards. RAYPCB can provide guidance on appropriate spacing for your specific components and manufacturing process. -

Q: What are the benefits of using multilayer PCBs?

A: Multilayer PCBs offer several advantages, including higher component density, improved signal integrity, and better power distribution. They allow for more complex designs and can help minimize EMI and crosstalk. -

Q: How can I optimize my PCB layout for high-speed applications?

A: To optimize your PCB layout for high-speed applications, use techniques such as controlled impedance traces, differential signaling, and length matching. Place high-speed components strategically and provide adequate spacing to minimize EMI and crosstalk. -

Q: How can RAYPCB assist in the PCB layout process?

A: RAYPCB offers a wide range of PCB manufacturing services and has a team of experienced engineers who can provide guidance and support in PCB layout. They can assist in selecting the right CAD tools, optimizing component placement, and ensuring compliance with design rules and manufacturing requirements.

Conclusion

Proper component placement is essential for achieving optimal performance, reliability, and manufacturability in PCB design. By following the guidelines and techniques outlined in this article, you can create PCB layouts that meet your specific design requirements and ensure the best possible results.

RAYPCB, with its extensive experience and expertise in PCB manufacturing, can be a valuable partner in your PCB layout journey. By leveraging their knowledge and support, you can streamline your design process, minimize potential issues, and achieve a successful PCB layout that meets your goals.

Remember to consider factors such as component orientation, grouping related components, thermal management, signal integrity, and manufacturability when placing components on your PCB. Use CAD tools effectively to automate and optimize the placement process, and consider advanced techniques such as multilayer PCB design and high-speed PCB design when necessary.

By following these best practices and partnering with a reliable PCB manufacturer like RAYPCB, you can create PCB layouts that excel in performance, reliability, and manufacturability, ultimately contributing to the success of your electronic devices.

No responses yet