Introduction to Regal TP and MAP Control

Regal TP (Throttle Position) and MAP (Manifold Absolute Pressure) are two essential components in modern automotive engine control systems. Together, they provide crucial input data to the Engine Control Unit (ECU), which uses this information to optimize fuel injection, ignition timing, and other engine parameters for optimal performance and efficiency. In this article, we will explore the Circuit diagram for a Regal TP and MAP control system, discussing its components, functionality, and troubleshooting techniques.

Understanding the Role of TP and MAP Sensors

Throttle Position Sensor (TP)

The Throttle Position Sensor (TP) is a potentiometer that monitors the position of the throttle valve in the throttle body. As the throttle valve opens and closes, the TP sensor provides a variable voltage signal to the ECU, indicating the current throttle position. This information is used by the ECU to determine the driver’s desired engine power output and adjust fuel injection and ignition timing accordingly.

Manifold Absolute Pressure Sensor (MAP)

The Manifold Absolute Pressure (MAP) sensor measures the absolute pressure inside the intake manifold. This pressure varies depending on the engine load and throttle position. The MAP sensor converts this pressure into an electrical signal, which is sent to the ECU. The ECU uses this information to calculate the air density and determine the appropriate amount of fuel to inject into the engine.

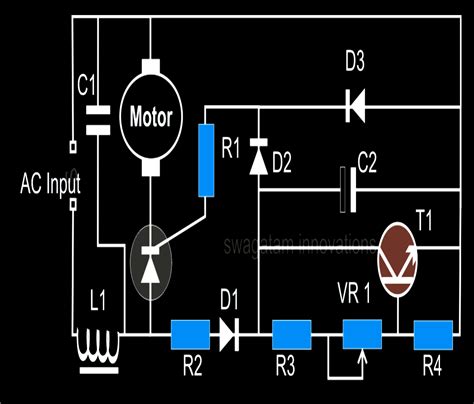

Regal TP and MAP Control Circuit Diagram

The Regal TP and MAP control circuit diagram illustrates the electrical connections and components involved in the TP and MAP sensor system. The diagram typically includes the following components:

- Throttle Position Sensor (TP)

- Manifold Absolute Pressure Sensor (MAP)

- Engine Control Unit (ECU)

- Wiring harness and connectors

- Power supply and ground connections

Circuit Diagram Components and Connections

| Component | Description | Connection |

|---|---|---|

| TP Sensor | Potentiometer that monitors throttle valve position | Signal wire to ECU, power supply, and ground |

| MAP Sensor | Measures absolute pressure in the intake manifold | Signal wire to ECU, power supply, and ground |

| ECU | Processes TP and MAP sensor signals to control engine functions | Receives signals from TP and MAP sensors |

| Wiring Harness | Connects sensors to the ECU and power supply | Provides electrical connections between components |

| Power Supply | Provides voltage to sensors and ECU | Connected to battery positive terminal |

| Ground | Provides a reference point for electrical signals | Connected to battery negative terminal or chassis |

The TP sensor is typically connected to the ECU via a 3-wire connection, with one wire for the signal, one for power supply, and one for ground. The MAP sensor also uses a 3-wire connection, with similar assignments for signal, power, and ground.

Interpreting the TP and MAP Sensor Signals

TP Sensor Signal

The TP sensor signal is a variable voltage that changes with the throttle valve position. When the throttle is fully closed (idle position), the TP sensor typically outputs a low voltage, around 0.5V. As the throttle opens, the voltage increases proportionally, reaching a maximum of about 4.5V when the throttle is fully open (wide open throttle, or WOT).

MAP Sensor Signal

The MAP sensor signal is also a variable voltage that changes with the manifold absolute pressure. When the engine is not running, the MAP sensor reads atmospheric pressure (around 101.3 kPa or 14.7 psi) and outputs a voltage of about 4.5V. As the engine runs and the manifold pressure decreases (higher vacuum), the MAP sensor voltage decreases proportionally. At high engine loads (low vacuum), the MAP sensor voltage will be closer to the atmospheric pressure reading.

Troubleshooting TP and MAP Sensor Issues

When diagnosing issues with the TP and MAP sensors, it’s essential to consult the circuit diagram and understand the proper voltage ranges for each sensor. Common problems include:

- Faulty sensors (internal damage or wear)

- Wiring issues (open, short, or high resistance connections)

- Contamination or damage to sensor connectors

- Incorrect sensor calibration

To troubleshoot these issues, technicians can use a digital multimeter to measure the sensor voltages and compare them to the expected values. They can also inspect the wiring and connectors for damage or contamination. In some cases, sensor calibration or replacement may be necessary.

Diagnostic Trouble Codes (DTCs)

When the ECU detects a problem with the TP or MAP sensor signals, it may store a Diagnostic Trouble Code (DTC) in its memory. These codes can be retrieved using an On-Board Diagnostics (OBD) scanner. Some common DTCs related to TP and MAP sensors include:

| DTC | Description |

|---|---|

| P0120 | Throttle Position Sensor Circuit Malfunction |

| P0121 | Throttle Position Sensor Circuit Range/Performance Problem |

| P0122 | Throttle Position Sensor Circuit Low Input |

| P0123 | Throttle Position Sensor Circuit High Input |

| P0105 | Manifold Absolute Pressure Circuit Malfunction |

| P0106 | Manifold Absolute Pressure Circuit Range/Performance Problem |

| P0107 | Manifold Absolute Pressure Circuit Low Input |

| P0108 | Manifold Absolute Pressure Circuit High Input |

When a DTC is present, technicians should consult the manufacturer’s service manual for specific diagnostic procedures and repair guidelines.

Conclusion

The Regal TP and MAP control circuit diagram is a crucial tool for understanding the interaction between these sensors and the ECU in modern automotive engine control systems. By providing accurate information about throttle position and manifold pressure, these sensors enable the ECU to optimize engine performance, efficiency, and emissions. Proper diagnosis and repair of TP and MAP sensor issues are essential for maintaining optimal engine function and preventing driveability problems.

Frequently Asked Questions (FAQ)

- What is the purpose of the Throttle Position Sensor (TP)?

-

The Throttle Position Sensor (TP) monitors the position of the throttle valve in the throttle body and sends a signal to the ECU, indicating the current throttle position. This information helps the ECU determine the driver’s desired engine power output.

-

How does the Manifold Absolute Pressure (MAP) sensor work?

-

The Manifold Absolute Pressure (MAP) sensor measures the absolute pressure inside the intake manifold and converts this pressure into an electrical signal. The ECU uses this signal to calculate air density and determine the appropriate amount of fuel to inject into the engine.

-

What are the typical voltage ranges for TP and MAP sensors?

-

The TP sensor typically outputs a voltage range from 0.5V (throttle closed) to 4.5V (throttle fully open). The MAP sensor outputs around 4.5V at atmospheric pressure and decreases proportionally as manifold pressure decreases.

-

How can I diagnose issues with the TP or MAP sensors?

-

To diagnose issues with the TP or MAP sensors, use a digital multimeter to measure sensor voltages and compare them to expected values. Inspect wiring and connectors for damage or contamination. Retrieve any stored Diagnostic Trouble Codes (DTCs) using an OBD scanner.

-

What should I do if I suspect a problem with the TP or MAP sensor?

- If you suspect a problem with the TP or MAP sensor, consult the manufacturer’s service manual for specific diagnostic procedures and repair guidelines. In some cases, sensor calibration or replacement may be necessary. It’s essential to address these issues promptly to maintain optimal engine performance and prevent further damage.

No responses yet