Introduction to PCB Gerber Export

Printed Circuit Boards (PCBs) are essential components in modern electronics. They provide a platform for mounting and interconnecting electronic components to create functional circuits. Designing a PCB involves using specialized software, such as Diptrace, which allows engineers and hobbyists to create custom PCB layouts.

Once the PCB design is complete, the next step is to generate files that can be sent to a PCB manufacturer for fabrication. The most common file format used for this purpose is Gerber. Gerber files contain all the necessary information required by the manufacturer to produce the PCB, including the copper layers, solder mask, silkscreen, and drill holes.

In this article, we will guide you through the process of exporting your Diptrace PCB design to Gerber files, ensuring that your PCB can be manufactured accurately and efficiently.

Understanding Gerber Files

What are Gerber Files?

Gerber files, named after the Gerber Systems Corp., are a standard file format used in the PCB industry for describing the printed circuit board images. They are ASCII text files that contain commands and coordinates defining the copper traces, pads, and other features of the PCB.

Each Gerber file represents a single layer of the PCB, such as the top copper layer, bottom copper layer, solder mask, or silkscreen. These files are used by PCB manufacturers to create the photoplots or stencils needed for the fabrication process.

Gerber File Extensions and Their Meanings

Gerber files use specific file extensions to identify the different layers of the PCB. Here are some common file extensions and their meanings:

| Extension | Layer |

|---|---|

| .GTL | Top Copper Layer |

| .GBL | Bottom Copper Layer |

| .GTS | Top Solder Mask |

| .GBS | Bottom Solder Mask |

| .GTO | Top Silkscreen |

| .GBO | Bottom Silkscreen |

| .GKO | Board Outline |

| .DRL | Drill File |

Understanding these file extensions is crucial when organizing and sending your Gerber files to the PCB manufacturer.

Preparing Your Diptrace PCB Design for Gerber Export

Before exporting your PCB design to Gerber files, it’s essential to ensure that your design is complete and error-free. Follow these steps to prepare your Diptrace PCB design for Gerber export:

-

Design Rule Check (DRC): Run a Design Rule Check in Diptrace to identify any design issues, such as overlapping traces, insufficient clearances, or missing connections. Resolve any errors or warnings before proceeding.

-

Board Outline: Make sure that your PCB has a clearly defined board outline. This outline will be used by the manufacturer to cut the PCB to its final shape.

-

Copper Layers: Verify that all your copper layers are correctly designed and named. Ensure that the traces and pads are within the board outline and adhere to the manufacturer’s specifications.

-

Solder Mask and Silkscreen: If your PCB requires solder mask and silkscreen layers, double-check that they are properly designed and aligned with the copper layers. Ensure that the text on the silkscreen is legible and correctly oriented.

-

Drill Holes: Check that all the necessary drill holes for through-hole components and vias are present in your design. Verify that the hole sizes are correct and meet the manufacturer’s requirements.

By carefully reviewing and preparing your Diptrace PCB design, you can minimize the chances of encountering issues during the manufacturing process.

Exporting Gerber Files from Diptrace

Once your PCB design is ready, follow these step-by-step instructions to export Gerber files from Diptrace:

-

Open your PCB design project in Diptrace.

-

Click on “File” in the main menu and select “Export”.

-

In the Export dialog box, choose “Gerber…” from the list of export options.

-

In the Gerber Export dialog box, you will see various settings and options for exporting your Gerber files.

-

Under “Output directory”, select the folder where you want to save your Gerber files.

-

In the “Layers” section, ensure that all the necessary layers for your PCB are selected. This typically includes the top and bottom copper layers, solder mask layers, silkscreen layers, and the board outline.

-

Set the “Resolution” to the desired value. A higher resolution will result in more precise Gerber files but larger file sizes. Consult with your PCB manufacturer for their recommended resolution.

-

Choose the appropriate “Units” for your Gerber files, either inches or millimeters.

-

In the “Drill holes” section, select the option to generate a separate drill file. This file will contain information about the locations and sizes of the drill holes on your PCB.

-

Click on the “Export” button to generate the Gerber files.

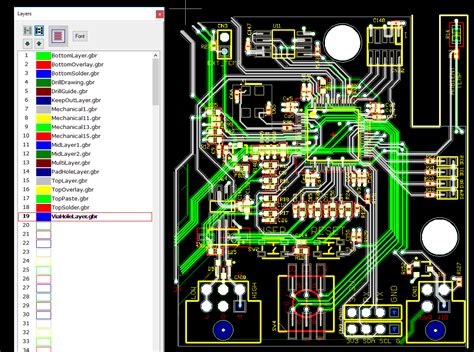

Diptrace will now create the Gerber files for your PCB design and save them in the specified output directory. The exported files will have the appropriate file extensions based on the layers you selected.

Verifying and Reviewing Gerber Files

After exporting your Gerber files, it’s crucial to verify and review them to ensure that they accurately represent your PCB design. Here are some steps to help you verify your Gerber files:

-

Visual Inspection: Use a Gerber viewer software, such as GC-Prevue or ViewMate, to open and visually inspect your Gerber files. Check that all the layers are present and correctly aligned.

-

Manufacturer’s Specifications: Compare your Gerber files against the PCB manufacturer’s specifications and requirements. Ensure that your files meet their guidelines for layer naming, file extensions, and resolution.

-

Design vs. Gerber Comparison: Overlay your original PCB design with the Gerber files to verify that they match. Look for any discrepancies, such as missing traces, incorrect pad sizes, or misaligned layers.

-

Automated Verification: Some PCB manufacturers provide online tools for verifying Gerber files. These tools can check your files for common errors and provide feedback on any issues that need to be addressed.

By thoroughly verifying and reviewing your Gerber files, you can catch any errors or inconsistencies before submitting them for manufacturing, saving time and potential costs associated with incorrect PCBs.

Submitting Gerber Files to a PCB Manufacturer

Once you have verified your Gerber files, you’re ready to submit them to a PCB manufacturer for fabrication. Follow these guidelines when submitting your files:

-

Compress Your Files: Compress all your Gerber files into a single ZIP or RAR archive. This makes it easier to transfer and ensures that no files are missed.

-

Naming Convention: Use a clear and descriptive naming convention for your compressed file, such as “ProjectName_Revision_Date.zip”.

-

Manufacturing Specifications: Include a document or README file that outlines your PCB’s manufacturing specifications, such as the desired PCB thickness, copper weight, solder mask color, and any special requirements.

-

Communication: Communicate clearly with your PCB manufacturer. Provide them with your contact information and be available to answer any questions they may have about your design or Gerber files.

-

Order Review: Carefully review your order details, including the quantity, lead time, and shipping method, before confirming your order with the manufacturer.

By following these guidelines, you can ensure a smooth and efficient PCB manufacturing process.

Frequently Asked Questions (FAQ)

-

What is the difference between Gerber files and drill files?

Gerber files contain information about the copper layers, solder mask, and silkscreen of a PCB, while drill files specifically contain information about the locations and sizes of the drill holes on the PCB. -

Can I use Diptrace to export Gerber files for a multi-layer PCB?

Yes, Diptrace supports the export of Gerber files for multi-layer PCBs. When exporting, ensure that you select all the necessary layers for your multi-layer design. -

What should I do if my PCB manufacturer reports issues with my Gerber files?

If your PCB manufacturer reports issues with your Gerber files, first verify that you have followed their specifications and requirements. If the issues persist, consult with the manufacturer to identify the specific problems and work with them to resolve any discrepancies or errors in your files. -

Can I use Gerber files generated from Diptrace with any PCB manufacturer?

Gerber files are a standard format used by most PCB manufacturers. However, it’s always a good idea to check with your specific manufacturer to ensure that they accept Gerber files generated from Diptrace and to confirm any specific requirements they may have. -

How can I ensure the accuracy of my Gerber files?

To ensure the accuracy of your Gerber files, start by thoroughly reviewing your PCB design in Diptrace. Run Design Rule Checks (DRC) to identify and resolve any design issues. After exporting your Gerber files, use a Gerber viewer to visually inspect them and compare them against your original design. Additionally, consider using automated verification tools provided by your PCB manufacturer to check for common errors or inconsistencies.

Conclusion

Exporting Diptrace PCB designs to Gerber files is a critical step in the PCB manufacturing process. By understanding the Gerber file format, preparing your design, and following the proper export procedures, you can ensure that your PCB design is accurately translated into a format that PCB manufacturers can use.

Remember to always verify and review your Gerber files before submitting them for manufacturing. This extra step can save you time, money, and potential headaches associated with incorrect or incomplete PCB fabrication.

By mastering the process of exporting Diptrace PCB designs to Gerber files, you’ll be well-equipped to bring your electronic projects to life, from concept to a fully manufactured PCB.

No responses yet