Introduction

When designing and manufacturing printed circuit boards (PCBs), one of the critical factors to consider is the relationship between the through hole pin length and the PCB thickness. This article will delve into the importance of selecting the appropriate pin length for your PCB design, the various factors that influence this decision, and the potential consequences of choosing the wrong pin length.

Understanding Through Hole Technology

Through hole technology is a method of mounting electronic components on a PCB by inserting their leads through drilled holes in the board and soldering them to pads on the opposite side. This technology has been widely used in the electronics industry for decades due to its reliability and strength in creating secure connections between components and the PCB.

Advantages of Through Hole Technology

- Mechanical strength: Through hole components provide a stronger mechanical bond to the PCB compared to Surface Mount Technology (SMT), making them ideal for applications that require high durability or are subject to vibration and shock.

- Ease of manual assembly: Through hole components are easier to manually install and solder, which can be advantageous for low-volume production or prototyping.

- Compatibility with high-power components: Some high-power components, such as transformers and large capacitors, are only available in through hole packages.

Disadvantages of Through Hole Technology

- Larger footprint: Through hole components require more space on the PCB compared to SMT Components, which can limit the overall component density and board miniaturization.

- Increased manufacturing time: Drilling holes and manual assembly of through hole components can be more time-consuming than SMT assembly processes.

- Higher cost for high-volume production: For large-scale production, through hole technology can be more expensive due to the increased assembly time and the need for additional drilling and plating processes.

Factors Affecting Pin Length Selection

When selecting the appropriate pin length for your through hole components, several factors must be considered to ensure proper assembly and functionality of your PCB.

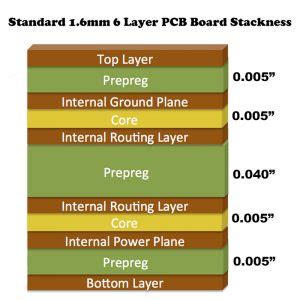

PCB Thickness

The thickness of your PCB is one of the primary factors that determine the required pin length for your through hole components. PCB thickness is typically measured in inches or millimeters and can vary depending on the number of layers, the material used, and the intended application of the board.

Common PCB thicknesses and their applications:

| PCB Thickness | Typical Applications |

|---|---|

| 0.8mm – 1.6mm | Consumer electronics, low-power devices |

| 1.6mm – 2.4mm | Industrial controls, automotive electronics |

| 2.4mm – 3.2mm | Military and aerospace electronics, high-power applications |

To ensure proper assembly and soldering, the pin length should be long enough to protrude through the PCB thickness and allow for adequate solder joint formation on the opposite side.

Component Lead Length

The lead length of your through hole components is another critical factor in determining the required pin length. Lead length refers to the portion of the component lead that extends from the component body to the PCB.

Manufacturers typically provide lead length specifications for their through hole components, which can help you determine the appropriate pin length for your design. It is essential to choose components with lead lengths that are compatible with your PCB thickness and assembly process.

Soldering Method

The soldering method used for your through hole components can also influence the required pin length. The two primary Soldering Methods for through hole components are wave soldering and hand soldering.

-

Wave soldering: In this automated process, the PCB is passed over a molten solder wave, which fills the through holes and creates solder joints. Wave soldering typically requires longer pin lengths to ensure adequate solder fill and joint formation.

-

Hand soldering: This manual process involves using a soldering iron to individually solder each component lead to the PCB. Hand soldering can accommodate shorter pin lengths compared to wave soldering, as the operator has more control over the solder joint formation.

Clearance Requirements

When selecting pin lengths, it is essential to consider clearance requirements between the bottom of the PCB and any other components, enclosures, or surfaces that may be present. Adequate clearance is necessary to prevent short circuits, mechanical interference, and potential damage to the components or PCB.

Factors that influence clearance requirements include:

- Enclosure design: If your PCB will be housed in an enclosure, ensure that the pin lengths do not interfere with the enclosure walls or other internal components.

- Component placement: Consider the placement and height of other components on the bottom side of the PCB, and ensure that the pin lengths do not create conflicts or short circuits.

- Mounting requirements: If your PCB will be mounted to a surface or chassis, account for the necessary clearance between the bottom of the PCB and the mounting surface.

PCB Thickness and Pin Length Compatibility

To ensure proper assembly and functionality of your through hole components, it is crucial to select pin lengths that are compatible with your PCB thickness. The following table provides general guidelines for matching pin lengths to common PCB thicknesses:

| PCB Thickness | Recommended Pin Length |

|---|---|

| 0.8mm – 1.6mm | 2.5mm – 3.5mm |

| 1.6mm – 2.4mm | 3.5mm – 4.5mm |

| 2.4mm – 3.2mm | 4.5mm – 6.0mm |

It is important to note that these are general guidelines, and the specific pin lengths required for your design may vary based on the factors discussed earlier, such as component lead length, soldering method, and clearance requirements.

Consequences of Incorrect Pin Length Selection

Choosing the wrong pin length for your through hole components can lead to various problems during assembly and operation of your PCB.

Insufficient Pin Length

If the selected pin length is too short for your PCB thickness, several issues may arise:

- Difficult or incomplete solder joint formation: Short pins may not protrude far enough through the PCB to allow for adequate solder fillets, resulting in weak or incomplete solder joints.

- Mechanical instability: Components with short pins may not have sufficient mechanical support, leading to instability and potential damage during handling or operation.

- Increased assembly time and cost: Attempting to solder components with insufficient pin lengths can be time-consuming and may require manual intervention, increasing assembly costs.

Excessive Pin Length

On the other hand, selecting pin lengths that are too long for your PCB thickness can also create problems:

- Interference with other components or enclosures: Long pins may interfere with other components on the bottom side of the PCB or with the enclosure, leading to short circuits or mechanical damage.

- Increased risk of bent pins: Longer pins are more susceptible to bending or deformation during handling and assembly, which can make insertion and soldering more difficult.

- Wasted material and increased cost: Using unnecessarily long pins can result in wasted material and increased component costs.

Best Practices for Pin Length Selection

To ensure optimal performance and reliability of your through hole components, consider the following best practices when selecting pin lengths:

- Consult manufacturer datasheets: Always refer to the manufacturer’s datasheets for your specific through hole components to determine the recommended lead lengths and compatibility with your PCB thickness.

- Allow for adequate clearance: Ensure that your selected pin lengths provide sufficient clearance between the bottom of the PCB and any other components, enclosures, or surfaces to prevent short circuits and mechanical interference.

- Consider the soldering method: If you plan to use wave soldering, opt for slightly longer pin lengths to ensure adequate solder fill and joint formation. For hand soldering, shorter pin lengths may be acceptable.

- Prototype and test: Before committing to a final pin length selection, prototype your design and test the assembly process to verify that the chosen pin lengths are compatible with your PCB thickness and assembly methods.

- Collaborate with your manufacturer: Work closely with your PCB manufacturer and assembly provider to ensure that your selected pin lengths are suitable for their processes and equipment, and make adjustments as necessary.

Conclusion

Selecting the appropriate pin length for your through hole components is a critical aspect of PCB design and assembly. By understanding the factors that influence pin length selection, such as PCB thickness, component lead length, soldering method, and clearance requirements, you can make informed decisions that ensure the reliability and functionality of your PCB.

By following best practices and collaborating with your manufacturing partners, you can optimize your pin length selection and avoid the potential consequences of choosing the wrong pin length, such as incomplete solder joints, mechanical instability, and interference with other components.

Ultimately, careful consideration of through hole pin length and PCB thickness compatibility will contribute to the success of your electronic design and help you create high-quality, reliable PCBs.

Frequently Asked Questions

-

What is the relationship between PCB thickness and through hole pin length?

The PCB thickness directly influences the required pin length for through hole components. Thicker PCBs generally require longer pin lengths to ensure adequate protrusion through the board and allow for proper solder joint formation on the opposite side. -

Can I use the same pin length for all my through hole components?

Not necessarily. Different through hole components may have varying lead lengths, and the required pin length may also depend on factors such as the soldering method and clearance requirements. It is essential to consider each component individually and consult manufacturer datasheets for recommended pin lengths. -

What happens if I choose a pin length that is too short for my PCB thickness?

If the pin length is insufficient for your PCB thickness, you may encounter issues such as difficult or incomplete solder joint formation, mechanical instability, and increased assembly time and cost. -

How do I determine the appropriate clearance requirements for my through hole components?

To determine clearance requirements, consider factors such as enclosure design, component placement on the bottom side of the PCB, and mounting requirements. Ensure that the selected pin lengths do not interfere with other components, enclosures, or surfaces to prevent short circuits and mechanical damage. -

What should I do if I am unsure about the appropriate pin length for my PCB design?

If you are unsure about the appropriate pin length for your PCB design, consult manufacturer datasheets for your specific through hole components, prototype and test your design, and collaborate with your PCB manufacturer and assembly provider to ensure compatibility with their processes and equipment.

No responses yet