Introduction to QFN Packages and Soldering Challenges

Quad Flat No-lead (QFN) packages have gained popularity in recent years due to their small size, excellent thermal and electrical performance, and low cost. However, soldering QFN packages can be challenging, especially for novice engineers or those unfamiliar with the unique characteristics of these packages. This article will discuss the board layout considerations for QFN packages to ensure more reliable soldering results.

What is a QFN Package?

A QFN package is a surface-mount technology (SMT) package with a leadless design. The package has a square or rectangular body with exposed pads on the bottom surface for soldering directly to the printed circuit board (PCB). The absence of leads reduces the package size and improves electrical and thermal performance compared to traditional leaded packages.

Challenges in Soldering QFN Packages

Despite their advantages, QFN packages present several challenges during the soldering process:

-

Limited access to solder joints: The lack of leads and the small gap between the package and the PCB make it difficult to inspect and rework solder joints.

-

Thermal dissipation: The exposed pad on the bottom of the package is designed to provide a thermal path for heat dissipation. Proper soldering of this pad is critical for optimal thermal performance.

-

Void formation: Voids can form in the solder joints, particularly under the exposed pad, which can compromise the mechanical and thermal integrity of the connection.

-

Tombstoning: Tombstoning occurs when one end of the package lifts off the PCB during soldering, resulting in a poor or open connection.

Board Layout Considerations for QFN Soldering

To minimize the challenges associated with soldering QFN packages, consider the following board layout guidelines:

Pad Design and Spacing

Proper pad design and spacing are essential for reliable QFN soldering. The pads should be designed according to the package manufacturer’s recommendations, taking into account the package size, pitch, and thermal requirements.

Pad Size

The pad size should be slightly larger than the package dimensions to allow for some placement tolerance and to ensure adequate solderable area. A typical recommendation is to extend the pads by 0.2-0.5 mm beyond the package outline.

| Package Size (mm) | Recommended Pad Extension (mm) |

|---|---|

| < 3×3 | 0.2 |

| 3×3 to 6×6 | 0.3 |

| > 6×6 | 0.5 |

Pad Spacing

The spacing between pads should be sufficient to prevent solder bridging while maintaining a compact layout. The minimum spacing depends on the package pitch and the PCB manufacturing capabilities.

| Package Pitch (mm) | Minimum Pad Spacing (mm) |

|---|---|

| 0.4 | 0.2 |

| 0.5 | 0.25 |

| 0.65 | 0.3 |

| 0.8 | 0.4 |

Exposed Pad Design

The exposed pad on the bottom of the QFN package serves as a thermal and electrical connection to the PCB. Proper design of the exposed pad is critical for optimal performance and reliable soldering.

Exposed Pad Size

The size of the exposed pad on the PCB should match the size of the exposed pad on the package. However, it is common practice to divide the exposed pad into smaller segments to improve solderability and reduce the risk of void formation.

Segmentation

Dividing the exposed pad into smaller segments helps to:

-

Prevent solder wicking: Smaller segments reduce the capillary action that can cause solder to wick away from the edges of the package.

-

Improve outgassing: The gaps between segments provide an escape path for gases that can form during soldering, reducing the risk of void formation.

-

Enhance solder joint reliability: Segmentation allows for some degree of thermal expansion mismatch between the package and the PCB, reducing stress on the solder joints.

A common segmentation pattern is a 3×3 or 4×4 grid, with a segment size of 1-2 mm and a gap of 0.2-0.3 mm between segments.

Solder Mask Design

Solder mask is a polymer coating applied to the PCB that protects the copper traces and prevents solder bridging. Proper solder mask design is essential for reliable QFN soldering.

Solder Mask Clearance

The solder mask should be pulled back from the edges of the pads to ensure adequate solderable area. The recommended solder mask clearance is 0.05-0.1 mm, depending on the package size and PCB manufacturing capabilities.

| Package Size (mm) | Recommended Solder Mask Clearance (mm) |

|---|---|

| < 3×3 | 0.05 |

| 3×3 to 6×6 | 0.075 |

| > 6×6 | 0.1 |

Solder Mask Between Pads

For fine-pitch QFN packages (0.5 mm or smaller), it is recommended to have solder mask between the pads to prevent solder bridging. However, for larger pitch packages, the solder mask can be omitted between pads to improve the solder joint strength.

Thermal Relief Design

Thermal relief design is essential for preventing thermal stress on the solder joints during soldering and operation. Thermal relief is achieved by connecting the exposed pad to the thermal vias using thin traces, known as thermal spokes.

Thermal Vias

Thermal vias are plated through-holes that transfer heat from the exposed pad to the inner layers or the opposite side of the PCB. The number and size of thermal vias depend on the package size and thermal requirements.

| Package Size (mm) | Number of Thermal Vias | Via Diameter (mm) |

|---|---|---|

| < 3×3 | 4 | 0.3 |

| 3×3 to 6×6 | 9 | 0.4 |

| > 6×6 | 16 | 0.5 |

Thermal Spokes

Thermal spokes are thin traces that connect the exposed pad to the thermal vias. The width and number of thermal spokes should be designed to provide adequate Thermal conductivity while minimizing the risk of solder wicking.

| Package Size (mm) | Number of Thermal Spokes | Spoke Width (mm) |

|---|---|---|

| < 3×3 | 4 | 0.2 |

| 3×3 to 6×6 | 6 | 0.25 |

| > 6×6 | 8 | 0.3 |

Stencil Design for QFN Soldering

Stencil design is crucial for achieving reliable solder joints when using solder paste for QFN packages. The stencil thickness, aperture size, and shape should be optimized based on the package size and solder paste properties.

Stencil Thickness

The stencil thickness determines the amount of solder paste deposited on the pads. A thicker stencil deposits more solder paste, which can lead to solder bridging or excess solder. A thinner stencil deposits less solder paste, which can result in insufficient solder joint strength.

The recommended stencil thickness for QFN packages is 0.1-0.15 mm, depending on the package size and pitch.

| Package Pitch (mm) | Recommended Stencil Thickness (mm) |

|---|---|

| 0.4 | 0.1 |

| 0.5 | 0.12 |

| 0.65 | 0.12 |

| 0.8 | 0.15 |

Aperture Size and Shape

The aperture size and shape in the stencil should be designed to match the pad size and shape on the PCB. However, some adjustments may be necessary to ensure optimal solder paste release and to prevent solder bridging.

Aperture Size

The aperture size should be slightly smaller than the pad size to account for the solder paste shrinkage during reflow. A typical recommendation is to reduce the aperture size by 10-20% compared to the pad size.

| Pad Size (mm) | Recommended Aperture Size Reduction (%) |

|---|---|

| < 0.5 | 20 |

| 0.5 to 1.0 | 15 |

| > 1.0 | 10 |

Aperture Shape

The aperture shape can be either square or circular, depending on the pad shape and the desired solder paste volume. Square apertures are more common for QFN packages, as they provide a larger area for solder paste deposition.

For fine-pitch QFN packages (0.5 mm or smaller), it may be necessary to use circular apertures to prevent solder bridging. The diameter of the circular aperture should be approximately 80% of the pad width.

Reflow Soldering Profile for QFN Packages

The reflow soldering profile is the temperature profile used to melt the solder paste and form the solder joints. A proper reflow profile is essential for achieving reliable solder joints and preventing defects such as voiding, tombstoning, or solder balling.

Reflow Profile Zones

A typical reflow profile consists of four zones:

- Preheat: The PCB and components are gradually heated to activate the flux and evaporate the solvents in the solder paste.

- Soak: The temperature is maintained to allow the components to reach a uniform temperature and to further activate the flux.

- Reflow: The temperature is increased above the melting point of the solder to form the solder joints.

- Cooling: The PCB and components are cooled down to solidify the solder joints.

Reflow Profile Parameters

The reflow profile parameters should be optimized based on the solder paste specifications and the thermal requirements of the components. The following table provides general guidelines for a lead-free reflow profile suitable for QFN packages:

| Reflow Profile Parameter | Recommended Value |

|---|---|

| Preheat ramp rate | 1-3°C/s |

| Preheat temperature | 150-180°C |

| Soak time | 60-120 s |

| Peak temperature | 235-245°C |

| Time above liquidus | 60-90 s |

| Cooling ramp rate | 1-4°C/s |

It is important to note that the actual reflow profile may need to be adjusted based on the specific solder paste, PCB design, and reflow oven characteristics. It is recommended to perform reflow profiling and optimization to ensure the best soldering results.

Inspection and Rework of QFN Solder Joints

Inspecting and reworking QFN solder joints can be challenging due to the limited access to the solder joints and the small size of the packages. However, proper inspection and rework techniques can help to identify and correct soldering defects.

Inspection Methods

There are several methods for inspecting QFN solder joints:

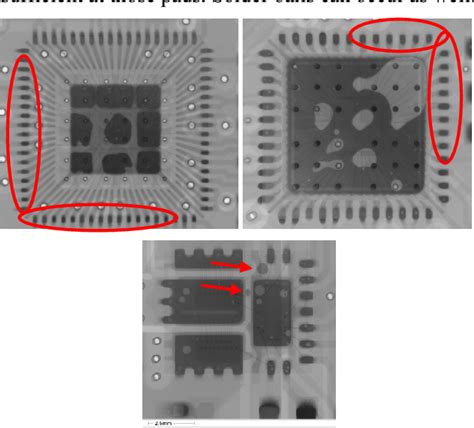

- Visual inspection: Visual inspection using a microscope or high-resolution camera can detect surface defects such as solder bridging, tombstoning, or insufficient solder.

- X-ray inspection: X-ray inspection can reveal internal defects such as voids, cracks, or poor solder coverage on the exposed pad.

- Thermal imaging: Thermal imaging can detect thermal anomalies that may indicate poor solder joint quality or thermal dissipation issues.

- Electrical testing: Electrical testing, such as continuity or functional testing, can identify open or short circuits caused by soldering defects.

Rework Techniques

If a soldering defect is detected, the QFN package may need to be reworked. The following techniques can be used for QFN rework:

- Hot air rework: A focused hot air nozzle is used to heat the QFN package and melt the solder joints. The package can then be removed and replaced with a new one.

- Soldering iron rework: A fine-tip soldering iron can be used to touch up individual solder joints or to remove solder bridges.

- Solder paste dispensing: If insufficient solder is detected, additional solder paste can be dispensed onto the pads using a syringe or automated dispensing system.

It is important to follow the manufacturer’s guidelines and use appropriate tools and techniques when reworking QFN packages to prevent damage to the package or the PCB.

Frequently Asked Questions (FAQ)

- What is the minimum pad size for a QFN package?

The minimum pad size for a QFN package depends on the package size and pitch. As a general guideline, the pad size should be at least 0.2 mm larger than the package dimensions to allow for placement tolerance and adequate solderable area.

- Can solder paste be applied directly to the exposed pad?

Yes, solder paste can be applied directly to the exposed pad using a stencil or solder paste dispensing system. However, it is important to control the solder paste volume to prevent excessive solder or voiding.

- What is the recommended reflow temperature for lead-free solder paste?

The recommended peak reflow temperature for lead-free solder paste is typically between 235°C and 245°C. However, the actual temperature may vary depending on the specific solder paste composition and the thermal requirements of the components.

- How can voids in QFN solder joints be prevented?

Voids in QFN solder joints can be prevented by optimizing the board layout, stencil design, and reflow profile. Some strategies include:

– Segmenting the exposed pad to improve outgassing

– Using a thinner stencil to reduce solder paste volume

– Optimizing the reflow profile to allow sufficient time for solder wetting and void escape

- What is the best way to remove a soldered QFN package?

The best way to remove a soldered QFN package is by using a hot air rework station. A focused hot air nozzle can be used to heat the package and melt the solder joints, allowing the package to be lifted off the PCB. It is important to use appropriate temperature settings and techniques to prevent damage to the package or the PCB.

Conclusion

Reliable soldering of QFN packages requires careful consideration of board layout, stencil design, reflow profile, and inspection and rework techniques. By following the guidelines presented in this article, engineers can design PCBs that are optimized for QFN soldering and minimize the risk of soldering defects.

Key takeaways from this article include:

- Proper pad design and spacing are essential for reliable QFN soldering

- The exposed pad should be segmented to improve solderability and reduce void formation

- Stencil thickness, aperture size, and shape should be optimized based on the package size and solder paste properties

- The reflow profile should be tailored to the specific solder paste and thermal requirements of the components

- Inspection and rework techniques can help to identify and correct soldering defects

By understanding and applying these principles, engineers can achieve high-quality and reliable solder joints for QFN packages, ensuring the performance and longevity of their electronic devices.

No responses yet