Introduction to Voltage Regulators

A voltage regulator is an essential component in electronic circuits that helps maintain a constant voltage level despite fluctuations in the input voltage or load current. It ensures that the connected devices receive a stable and reliable power supply, preventing damage from overvoltage or undervoltage conditions. In this article, we will explore the concept of automatic voltage regulators (AVRs) and focus on setting up the PCB circuit for a generating set.

Types of Voltage Regulators

There are two main types of voltage regulators:

- Linear Voltage Regulators

- Shunt regulators

-

Series regulators

-

Switching Voltage Regulators

- Buck converters (step-down)

- Boost converters (step-up)

- Buck-boost converters (step-up/step-down)

Automatic Voltage Regulators (AVRs)

An automatic voltage regulator (AVR) is a closed-loop control system that automatically maintains the output voltage of a generator at a desired level. It continuously monitors the generator’s output voltage and adjusts the excitation current to the generator’s field winding to compensate for any changes in the load or input voltage.

Components of an AVR

The key components of an automatic voltage regulator include:

- Voltage sensing circuit

- Error amplifier

- Excitation control system

- Power supply

- Protection circuits

How an AVR Works

The working principle of an AVR can be summarized as follows:

- The voltage sensing circuit measures the generator’s output voltage.

- The sensed voltage is compared with a reference voltage using an error amplifier.

- The error signal is amplified and used to control the excitation current to the generator’s field winding.

- If the output voltage is too low, the AVR increases the excitation current, and if the output voltage is too high, it decreases the excitation current.

- This closed-loop control system continuously adjusts the excitation current to maintain a stable output voltage.

Designing the AVR PCB Circuit

Schematic Design

The first step in designing the AVR PCB circuit is to create a schematic diagram that includes all the necessary components and their interconnections. The schematic should include:

- Voltage sensing circuit

- Error amplifier

- Excitation control system (power transistors or thyristors)

- Voltage reference

- Protection circuits (over-voltage, under-voltage, over-current)

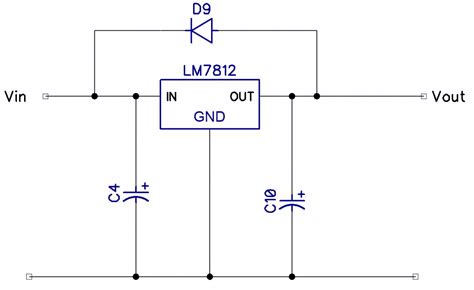

- Power supply

Component Selection

When selecting components for the AVR PCB circuit, consider the following factors:

- Voltage and current ratings

- Accuracy and stability

- Temperature coefficient

- Package size and type

- Cost and availability

Some common components used in AVR circuits include:

| Component | Purpose |

|---|---|

| Voltage transformer | Step down generator output for sensing |

| Rectifier diodes | Convert AC to DC for voltage sensing |

| Op-amps | Error amplification and signal conditioning |

| Power transistors | Control excitation current |

| Voltage reference | Provide stable reference voltage |

| Resistors, capacitors | Filtering, biasing, and protection |

PCB Layout Considerations

When designing the PCB layout for the AVR circuit, keep the following best practices in mind:

- Minimizing noise and interference

- Keep high-current traces separate from sensitive analog signals

- Use proper grounding techniques and ground planes

-

Decouple power supplies with bypass capacitors near ICs

-

Thermal management

- Provide adequate copper area for power dissipation

- Use thermal reliefs for components with high heat generation

-

Consider using heatsinks for power transistors or voltage regulators

-

Component placement

- Group related components together for shorter traces and better performance

- Place sensitive components away from noise sources

-

Ensure proper clearance between components and traces

-

Signal integrity

- Use appropriate trace widths for current carrying capacity

- Avoid sharp bends or corners in traces to minimize reflections

- Match trace lengths for critical signals to avoid timing issues

Manufacturing and Testing

PCB Fabrication

Once the PCB layout is complete, the design files (Gerber and drill files) can be sent to a PCB manufacturer for fabrication. Consider the following when choosing a PCB fabrication service:

- PCB material (FR-4, high-Tg, etc.)

- Copper weight and thickness

- Solder mask and silkscreen options

- Lead time and cost

Assembly and Soldering

After receiving the fabricated PCBs, the components can be soldered onto the board. There are two main methods of soldering:

- Through-hole soldering

- Components have leads that are inserted through holes in the PCB

- Soldering is done on the opposite side of the component placement

-

Suitable for larger components and manual soldering

-

Surface-mount soldering

- Components have flat leads or pads that are soldered directly onto the PCB surface

- Requires precise placement and reflow soldering techniques

- Allows for smaller components and higher density layouts

Testing and Calibration

Before integrating the AVR PCB circuit into the generating set, it is essential to perform thorough testing and calibration. This includes:

- Visual inspection for any soldering defects or component issues

- Power-on testing to verify proper voltage levels and regulation

- Load testing to ensure stable output voltage under various load conditions

- Calibration of the voltage sensing circuit and error amplifier

- Verification of protection circuits (over-voltage, under-voltage, over-current)

Integration and Maintenance

Mounting and Wiring

When integrating the AVR PCB circuit into the generating set, consider the following:

- Mounting location and orientation

- Ensure proper clearance and access for maintenance

-

Protect the PCB from vibration, moisture, and extreme temperatures

-

Wiring and connections

- Use appropriate wire gauges for current carrying capacity

- Secure wires with strain reliefs or cable ties

- Label wires for easy identification and troubleshooting

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential for the reliable operation of the AVR and generating set. Some key aspects include:

- Periodic visual inspection for any signs of damage, corrosion, or loose connections

- Cleaning of the PCB and components to remove dust and debris

- Retightening of terminal connections and mounting hardware

- Monitoring of voltage levels and regulation performance

- Replacement of any faulty components or PCBs

Conclusion

Designing and setting up the automatic voltage regulator PCB circuit for a generating set requires careful consideration of various factors, including component selection, PCB layout, manufacturing, testing, and integration. By following best practices and guidelines, a reliable and efficient AVR system can be implemented to ensure stable and regulated output voltage for the connected loads.

Frequently Asked Questions (FAQ)

- What is the purpose of an automatic voltage regulator in a generating set?

-

An automatic voltage regulator (AVR) maintains a stable output voltage from the generator by continuously monitoring and adjusting the excitation current to the generator’s field winding. It compensates for changes in the load or input voltage to ensure a constant voltage supply to the connected equipment.

-

What are the main components of an AVR PCB circuit?

-

The main components of an AVR PCB circuit include a voltage sensing circuit, error amplifier, excitation control system (power transistors or thyristors), voltage reference, protection circuits (over-voltage, under-voltage, over-current), and power supply.

-

What factors should be considered when selecting components for the AVR PCB circuit?

-

When selecting components for the AVR PCB circuit, consider factors such as voltage and current ratings, accuracy and stability, temperature coefficient, package size and type, and cost and availability. It is essential to choose components that meet the specific requirements of the generating set and ensure reliable operation.

-

What are some best practices for designing the PCB layout of an AVR circuit?

-

Some best practices for designing the PCB layout of an AVR circuit include minimizing noise and interference by keeping high-current traces separate from sensitive analog signals, using proper grounding techniques and ground planes, and decoupling power supplies with bypass capacitors near ICs. Thermal management, component placement, and signal integrity should also be considered to ensure optimal performance and reliability.

-

What are the steps involved in testing and calibrating the AVR PCB circuit before integration into the generating set?

- The steps involved in testing and calibrating the AVR PCB circuit include visual inspection for any soldering defects or component issues, power-on testing to verify proper voltage levels and regulation, load testing to ensure stable output voltage under various load conditions, calibration of the voltage sensing circuit and error amplifier, and verification of protection circuits (over-voltage, under-voltage, over-current). These steps ensure that the AVR PCB circuit functions as intended and provides reliable voltage regulation for the generating set.

No responses yet