Introduction to Desoldering PCBs

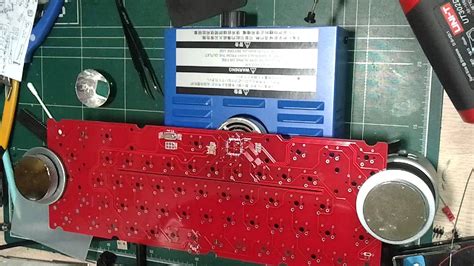

Printed Circuit Boards (PCBs) are an essential component in modern electronics. They are used to mechanically support and electrically connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. However, when a PCB reaches the end of its life or needs to be repaired, it is often necessary to remove the metal components from the board. This process is known as desoldering.

Desoldering is the process of removing solder and components from a PCB. It is a crucial skill for anyone who works with electronics, as it allows for the salvage of valuable components and the repair of damaged boards. In this article, we will explore the various methods and techniques used for desoldering PCBs, as well as the tools and safety precautions required.

Why Desolder PCBs?

There are several reasons why you might need to desolder a PCB:

-

Repair: If a component on a PCB is damaged or not functioning correctly, desoldering allows you to remove and replace it.

-

Salvage: PCBs often contain valuable components such as capacitors, resistors, and integrated circuits. Desoldering allows you to salvage these components for use in other projects.

-

Recycling: PCBs contain a variety of metals, including copper, gold, and silver. Desoldering allows you to separate these metals from the non-metallic substrate for recycling.

-

Prototyping: When creating a new PCB design, you may need to desolder components from an existing board to use in your prototype.

Tools Required for Desoldering PCBs

To effectively desolder a PCB, you will need the following tools:

-

Soldering Iron: A soldering iron is a hand tool used to melt solder and remove components from a PCB. When choosing a soldering iron for desoldering, look for one with adjustable temperature control and a high wattage (40-60 watts).

-

Desoldering Pump: Also known as a solder sucker, a desoldering pump is a manual vacuum pump used to remove molten solder from a PCB. It works by creating a vacuum that sucks up the solder when the trigger is released.

-

Desoldering Wick: Also known as desoldering braid, desoldering wick is a copper braid that is used to absorb molten solder from a PCB. It works by placing the wick over the solder joint and heating it with a soldering iron, which causes the solder to wick up into the braid.

-

Tweezers: Tweezers are used to grab and remove small components from a PCB after the solder has been removed.

-

Safety Equipment: When desoldering, it is important to wear safety glasses and a respirator mask to protect yourself from lead fumes. You should also work in a well-ventilated area and avoid touching the hot soldering iron tip.

Methods for Desoldering PCBs

There are several methods for desoldering PCBs, each with its own advantages and disadvantages.

Desoldering with a Soldering Iron and Pump

This is the most common method for desoldering PCBs. To use this method:

- Heat up the soldering iron to the appropriate temperature for the type of solder used on the PCB.

- Place the tip of the soldering iron on the solder joint you wish to remove, and wait for the solder to melt.

- Once the solder has melted, quickly place the nozzle of the desoldering pump over the joint and release the trigger. The vacuum will suck up the molten solder.

- Repeat steps 2 and 3 until all of the solder has been removed from the joint.

- Use tweezers to remove the component from the PCB.

Advantages:

– Inexpensive

– Readily available tools

– Suitable for small components and low-volume desoldering

Disadvantages:

– Can be time-consuming for large components or high-volume desoldering

– Requires manual dexterity and skill

– May damage PCB if not done carefully

Desoldering with a Desoldering Wick

This method uses a copper braid to absorb molten solder from the PCB. To use this method:

- Cut a length of desoldering wick and place it over the solder joint you wish to remove.

- Heat up the soldering iron to the appropriate temperature for the type of solder used on the PCB.

- Place the tip of the soldering iron on top of the desoldering wick, and wait for the solder to melt and wick up into the braid.

- Once the solder has been absorbed into the wick, remove the wick and soldering iron from the joint.

- Repeat steps 1-4 until all of the solder has been removed from the joint.

- Use tweezers to remove the component from the PCB.

Advantages:

– Suitable for larger components or high-volume desoldering

– Less likely to damage PCB than desoldering pump method

– Can remove solder from hard-to-reach areas

Disadvantages:

– More expensive than desoldering pump method

– Requires more skill and practice to use effectively

– May leave residue on PCB if not used correctly

Desoldering with a Desoldering Station

A desoldering station is a specialized tool that combines a soldering iron with a vacuum pump and heated nozzle. To use this method:

- Set the temperature and vacuum strength on the desoldering station to the appropriate levels for the type of solder and components used on the PCB.

- Place the heated nozzle over the solder joint you wish to remove, and wait for the solder to melt.

- Once the solder has melted, activate the vacuum pump to suck up the molten solder.

- Repeat steps 2 and 3 until all of the solder has been removed from the joint.

- Use tweezers to remove the component from the PCB.

Advantages:

– Fast and efficient for high-volume desoldering

– Adjustable temperature and vacuum strength for different types of solder and components

– Less likely to damage PCB than other methods

Disadvantages:

– Expensive compared to other methods

– Requires training and practice to use effectively

– May not be suitable for small or delicate components

Safety Precautions for Desoldering PCBs

Desoldering PCBs can be dangerous if proper safety precautions are not taken. Here are some important safety tips to keep in mind:

-

Wear Safety Equipment: Always wear safety glasses and a respirator mask when desoldering to protect yourself from lead fumes and other hazardous materials.

-

Work in a Well-Ventilated Area: Desoldering produces fumes that can be harmful if inhaled. Make sure to work in a well-ventilated area, such as outdoors or near an open window.

-

Avoid Touching Hot Surfaces: The soldering iron and molten solder can cause severe burns if touched. Use caution when handling the soldering iron and always place it in a stand when not in use.

-

Dispose of Waste Properly: Desoldering produces waste, such as used solder and desoldering wick, that can be harmful to the environment if not disposed of properly. Follow local regulations for disposing of hazardous waste.

Techniques for Effective Desoldering

Here are some techniques that can help you effectively desolder PCBs:

-

Use Flux: Applying flux to the solder joint before desoldering can help the solder melt more easily and prevent oxidation. Use a flux pen or brush to apply a small amount of flux to the joint before heating it with the soldering iron.

-

Use the Right Temperature: Using the right temperature is crucial for effective desoldering. If the temperature is too low, the solder will not melt completely, making it difficult to remove. If the temperature is too high, it can damage the PCB or components. Use a soldering iron with adjustable temperature control and set it to the appropriate temperature for the type of solder used on the PCB.

-

Work Quickly: Once the solder has melted, work quickly to remove it with the desoldering pump or wick. If the solder cools and hardens again, it will be more difficult to remove.

-

Clean the PCB: After desoldering, clean the PCB with isopropyl alcohol to remove any flux residue or debris. This will help prevent corrosion and ensure good electrical contact when soldering new components.

Common Mistakes to Avoid When Desoldering PCBs

Here are some common mistakes to avoid when desoldering PCBs:

-

Using Too Much Heat: Using too much heat can damage the PCB or components. Use the lowest temperature that will effectively melt the solder, and avoid leaving the soldering iron on the joint for too long.

-

Using the Wrong Tools: Using the wrong tools can make desoldering more difficult and increase the risk of damaging the PCB. Make sure to use the appropriate tools for the job, such as a high-wattage soldering iron and desoldering pump or wick.

-

Not Cleaning the PCB: Failing to clean the PCB after desoldering can lead to corrosion and poor electrical contact when soldering new components. Always clean the PCB with isopropyl alcohol after desoldering.

-

Rushing the Process: Desoldering can be time-consuming, but rushing the process can lead to mistakes and damage to the PCB. Take your time and work carefully to ensure the best results.

FAQ

- What is the best method for desoldering PCBs?

The best method for desoldering PCBs depends on the specific situation. For small components or low-volume desoldering, using a soldering iron and desoldering pump or wick may be sufficient. For larger components or high-volume desoldering, a desoldering station may be more efficient.

- Can I reuse components after desoldering them from a PCB?

In most cases, components can be reused after desoldering them from a PCB. However, it is important to inspect each component carefully for damage before reusing it. Some components, such as electrolytic capacitors, may be damaged by the heat of desoldering and should not be reused.

- How do I dispose of waste from desoldering PCBs?

Waste from desoldering PCBs, such as used solder and desoldering wick, should be disposed of according to local regulations for hazardous waste. In some cases, this may involve taking the waste to a special collection facility. Do not dispose of desoldering waste in the regular trash or down the drain.

- Can I desolder PCBs without using lead-based solder?

Yes, it is possible to desolder PCBs without using lead-based solder. There are lead-free solders available that can be used for desoldering, although they may require higher temperatures and different techniques than lead-based solders. It is important to use the appropriate type of solder and flux for the specific application.

- What safety equipment should I use when desoldering PCBs?

When desoldering PCBs, it is important to wear safety glasses and a respirator mask to protect yourself from lead fumes and other hazardous materials. You should also work in a well-ventilated area and avoid touching the hot soldering iron tip or molten solder. Wear heat-resistant gloves to protect your hands from burns.

Conclusion

Desoldering PCBs is an essential skill for anyone who works with electronics. Whether you need to repair a damaged board, salvage valuable components, or recycle the metals, desoldering allows you to separate the components from the PCB substrate. By using the right tools and techniques, and following important safety precautions, you can effectively desolder PCBs and achieve the best possible results.

| Method | Advantages | Disadvantages |

|---|---|---|

| Soldering Iron and Pump | – Inexpensive – Readily available tools – Suitable for small components and low-volume desoldering |

– Can be time-consuming for large components or high-volume desoldering – Requires manual dexterity and skill – May damage PCB if not done carefully |

| Desoldering Wick | – Suitable for larger components or high-volume desoldering – Less likely to damage PCB than desoldering pump method – Can remove solder from hard-to-reach areas |

– More expensive than desoldering pump method – Requires more skill and practice to use effectively – May leave residue on PCB if not used correctly |

| Desoldering Station | – Fast and efficient for high-volume desoldering – Adjustable temperature and vacuum strength for different types of solder and components – Less likely to damage PCB than other methods |

– Expensive compared to other methods – Requires training and practice to use effectively – May not be suitable for small or delicate components |

Remember to always prioritize safety when desoldering PCBs, and take the time to work carefully and methodically to achieve the best possible results. With practice and attention to detail, you can become proficient at desoldering PCBs and salvaging valuable components for reuse or recycling.

No responses yet