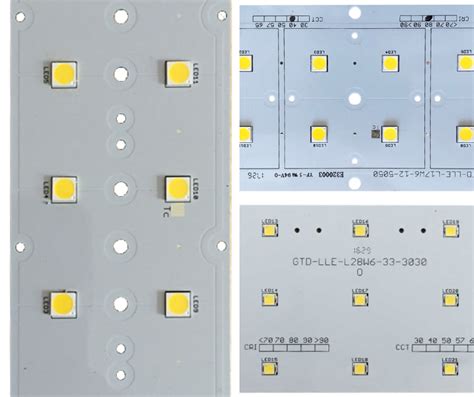

Introduction to PCB-LED Mounting

Surface-mount device (SMD) LEDs are widely used in modern electronics due to their small size, high efficiency, and ease of assembly. To ensure proper functioning and longevity of these PCB-LEDs, it is crucial to mount them correctly on printed circuit boards (PCBs). In this comprehensive guide, we will explore the various techniques, considerations, and best practices for mounting SMD LEDs on PCBs.

Understanding SMD LEDs and PCB-LED Compatibility

SMD LEDs come in various packages, each with its own set of dimensions and characteristics. Some common SMD LED packages include:

| Package | Dimensions (mm) | Typical Applications |

|---|---|---|

| 0402 | 1.0 x 0.5 | Compact devices |

| 0603 | 1.6 x 0.8 | General-purpose |

| 0805 | 2.0 x 1.25 | High-power lighting |

| 1206 | 3.2 x 1.6 | Automotive, outdoor |

When selecting SMD LEDs for your PCB-LED project, consider the following factors:

– LED package size and compatibility with your PCB design

– LED power requirements and heat dissipation needs

– LED color and brightness specifications

– LED viewing angle and light distribution pattern

Choosing the Right PCB Material for LED Mounting

The choice of PCB material plays a significant role in the successful mounting of SMD LEDs. The most common PCB Materials for LED applications include:

- FR-4: A cost-effective, flame-retardant material with good electrical insulation properties.

- Aluminum PCBs: Offer excellent Thermal conductivity for heat dissipation, ideal for high-power LEDs.

- Flexible PCBs: Suitable for applications requiring conformity to curved surfaces or tight spaces.

Consider the thermal, electrical, and mechanical requirements of your PCB-LED project when selecting the appropriate PCB material.

PCB-LED Layout and Design Considerations

Proper PCB-LED layout and design are essential for optimal LED performance and reliability. Follow these guidelines:

LED Placement and Orientation

- Place LEDs away from heat-sensitive components to minimize thermal interference.

- Orient LEDs consistently to ensure uniform light output and simplify assembly.

- Maintain adequate spacing between LEDs to prevent optical cross-talk and thermal coupling.

Trace Width and Thickness

- Use appropriate trace widths to handle the required LED current without excessive voltage drop.

- Increase trace thickness in high-current areas to improve current-carrying capacity and heat dissipation.

Thermal Management

- Incorporate thermal vias near LED pads to transfer heat from the LED to the PCB’s ground plane.

- Use copper pours or heat spreaders to distribute heat evenly across the PCB.

- Consider adding thermal interface materials (TIMs) between the LED and PCB for enhanced heat transfer.

SMD LED Soldering Techniques

Soldering SMD LEDs to PCBs requires precision and care to ensure proper electrical and mechanical connections. Two common soldering techniques are:

- Reflow Soldering:

- Apply solder paste to the PCB pads using a stencil or dispenser.

- Place the SMD LEDs onto the solder paste using pick-and-place equipment or tweezers.

-

Pass the PCB through a reflow oven, following a specific temperature profile to melt the solder and form a bond.

-

Hand Soldering:

- Use a fine-tipped soldering iron with temperature control.

- Apply a small amount of solder to one of the LED pads on the PCB.

- Position the LED using tweezers and hold it in place while applying heat to the solder joint.

- Quickly remove the soldering iron and allow the joint to cool before soldering the remaining pads.

Soldering Tips for PCB-LED Mounting

- Use solder wire with the appropriate diameter and alloy composition for your application.

- Maintain a consistent soldering temperature to prevent overheating or underheating the LED.

- Avoid applying excessive pressure on the LED during soldering to prevent damage.

- Inspect the solder joints for proper wetting, filleting, and absence of bridges or shorts.

PCB-LED Testing and Quality Control

After mounting the SMD LEDs on the PCB, it is essential to perform thorough testing and quality control to ensure proper functionality and reliability. Some key steps include:

- Visual Inspection:

- Check for proper LED alignment and orientation.

- Inspect solder joints for irregularities, such as bridging, insufficient wetting, or excessive solder.

-

Verify the absence of physical damage to the LEDs or PCB.

-

Electrical Testing:

- Measure the forward voltage and current of each LED to ensure compliance with specifications.

- Test the LED brightness and color consistency using a photometer or colorimeter.

-

Perform continuity tests to detect open circuits or short circuits.

-

Thermal Imaging:

- Use a thermal camera to identify hot spots or uneven heat distribution on the PCB.

-

Verify that the LED junction temperature remains within the specified limits during operation.

-

Burn-In Testing:

- Subject the PCB-LED assembly to an extended period of operation at elevated temperatures.

- Monitor the LED performance and look for any signs of degradation or failure.

Implementing a robust quality control process helps identify and address any issues early in the production cycle, improving the overall reliability and performance of your PCB-LED product.

Troubleshooting Common PCB-LED Mounting Issues

Despite careful design and assembly, problems may arise during PCB-LED mounting. Here are some common issues and their potential solutions:

- LED Not Illuminating:

- Check for proper polarity and orientation of the LED.

- Verify the continuity of the LED and its connections using a multimeter.

-

Ensure the LED is receiving the correct forward voltage and current.

-

Uneven or Inconsistent Brightness:

- Verify that all LEDs are from the same bin and have consistent specifications.

- Check for variations in solder joint quality or trace resistance.

-

Ensure proper thermal management to prevent localized overheating.

-

LED Color Shift:

- Ensure the LED is operating within its specified temperature range.

- Verify that the LED is not being subjected to excessive current or voltage.

-

Consider using LEDs with better color stability and consistency.

-

Solder Joint Failure:

- Inspect the solder joints for insufficient wetting, bridging, or poor adhesion.

- Verify that the solder paste and reflow profile are suitable for the LED and PCB.

- Ensure proper cleaning of the PCB and LED pads before soldering.

By understanding the root causes of these issues and implementing appropriate corrective actions, you can improve the reliability and performance of your PCB-LED assembly.

FAQ

- What is the difference between SMD LEDs and through-hole LEDs?

-

SMD LEDs are surface-mounted devices that are soldered directly onto the PCB, while through-hole LEDs have leads that are inserted into holes drilled in the PCB and soldered on the opposite side.

-

Can I mix different SMD LED packages on the same PCB?

-

While it is possible to mix different SMD LED packages, it is generally recommended to use LEDs with the same package size and specifications to ensure consistent brightness, color, and thermal characteristics.

-

How do I determine the appropriate trace width for my PCB-LED design?

-

The trace width depends on the maximum current required by the LED and the desired voltage drop. You can use online trace width calculators or consult the IPC-2221 standard for guidance.

-

What is the purpose of thermal vias in PCB-LED mounting?

-

Thermal vias help transfer heat generated by the LED from the top layer of the PCB to the ground plane or other heat-dissipating layers, improving thermal management and preventing overheating.

-

How can I ensure consistent LED color and brightness across multiple PCBs?

- To ensure consistency, use LEDs from the same bin and manufacturer, maintain tight control over the PCB fabrication and assembly processes, and implement strict quality control measures, including visual inspection and optical testing.

Conclusion

Mounting SMD LEDs on PCBs requires careful consideration of various factors, including LED selection, PCB material, layout, soldering techniques, and quality control. By following best practices and guidelines, you can achieve reliable and high-performance PCB-LED assemblies for a wide range of applications.

Remember to prioritize thermal management, maintain consistent manufacturing processes, and perform thorough testing and inspection to ensure the long-term reliability and functionality of your PCB-LED products. With the knowledge gained from this comprehensive guide, you are well-equipped to tackle your next PCB-LED mounting project with confidence and success.

No responses yet