Introduction to Battery charging circuits

Battery charging circuits are essential components in various electronic devices and systems that rely on rechargeable batteries, such as sealed lead acid (SLA) batteries. These circuits ensure that the batteries are charged efficiently and safely, prolonging their lifespan and optimizing their performance. In this article, we will explore the fundamentals of sealed lead acid battery charging circuits, their components, and how they work together to maintain the health and functionality of SLA batteries.

Understanding Sealed Lead Acid Batteries

Sealed lead acid batteries, also known as valve-regulated lead acid (VRLA) batteries, are rechargeable batteries that offer several advantages over traditional flooded lead acid batteries. These advantages include:

- Maintenance-free operation

- Spill-proof design

- Higher energy density

- Longer lifespan

- Improved safety

SLA batteries find applications in various fields, such as:

- Uninterruptible power supplies (UPS)

- Emergency lighting systems

- Security systems

- Medical equipment

- Telecommunications

To ensure optimal performance and longevity of SLA batteries, it is crucial to use a well-designed battery charging circuit that adheres to the specific charging requirements of these batteries.

Battery Charging Circuit Components

A typical sealed lead acid battery charging circuit consists of several key components that work together to regulate the charging process. These components include:

- Power supply

- Voltage regulator

- Current limiter

- Temperature sensor

- Charge controller

Power Supply

The power supply is responsible for providing the necessary voltage and current to charge the SLA battery. The power supply can be an AC adapter, a DC power source, or a solar panel, depending on the application and the available power sources.

Voltage Regulator

The voltage regulator maintains a constant voltage output to the battery, ensuring that the battery is charged at the appropriate voltage level. SLA batteries typically require a charging voltage of 2.25 to 2.30 volts per cell, which translates to 13.5 to 13.8 volts for a 12V battery.

Current Limiter

The current limiter restricts the maximum current that can flow into the battery during the charging process. This is important to prevent overheating and damage to the battery. The current limit is usually set to a fraction of the battery’s capacity, typically around 0.1C to 0.3C (where C is the battery’s capacity in amp-hours).

Temperature Sensor

The temperature sensor monitors the battery’s temperature during the charging process. SLA batteries are sensitive to temperature, and overheating can lead to reduced lifespan and even permanent damage. The temperature sensor provides feedback to the charge controller, which can adjust the charging parameters accordingly.

Charge Controller

The charge controller is the brain of the battery charging circuit. It receives input from the voltage regulator, current limiter, and temperature sensor, and adjusts the charging process based on these inputs. The charge controller implements the appropriate charging algorithm for SLA batteries, which typically involves three stages:

- Bulk stage: The battery is charged at a constant current until it reaches the maximum charging voltage.

- Absorption stage: The battery is charged at a constant voltage, while the current gradually decreases until the battery is fully charged.

- Float stage: The battery is maintained at a lower voltage to compensate for self-discharge and keep the battery fully charged.

Sealed Lead Acid Battery Charging Circuit diagram

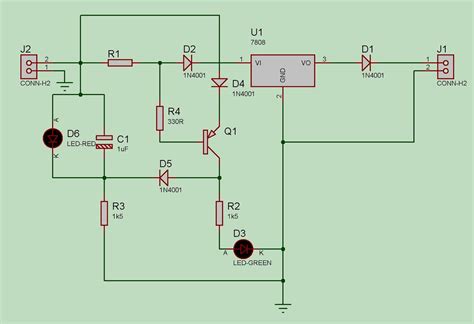

Now that we have covered the basic components of a sealed lead acid battery charging circuit, let’s dive into a sample circuit diagram.

Figure 1: Sealed Lead Acid Battery Charging Circuit Diagram

In this diagram, we have:

- A power supply providing the necessary voltage and current for charging the SLA battery.

- A voltage regulator (U1) that maintains a constant charging voltage.

- A current limiter (R1 and Q1) that restricts the maximum charging current.

- A temperature sensor (TH1) that monitors the battery’s temperature.

- A charge controller (U2) that implements the three-stage charging algorithm based on the inputs from the voltage regulator, current limiter, and temperature sensor.

The values of the components in the circuit may vary depending on the specific SLA battery being charged and the desired charging parameters. It is essential to refer to the battery manufacturer’s specifications and datasheets when designing a custom charging circuit.

Charging Algorithms for Sealed Lead Acid Batteries

As mentioned earlier, sealed lead acid batteries typically require a three-stage charging algorithm to ensure optimal charging and long-term health. Let’s take a closer look at each stage:

Bulk Stage

In the bulk stage, the battery is charged at a constant current, usually around 0.1C to 0.3C, until it reaches the maximum charging voltage (2.25 to 2.30 volts per cell). During this stage, the battery can accept a high charging current, and the voltage gradually increases.

The bulk stage is the fastest part of the charging process, and it typically charges the battery to around 70-80% of its capacity.

Absorption Stage

Once the battery reaches the maximum charging voltage, the charging process enters the absorption stage. In this stage, the voltage is held constant at the maximum charging voltage, while the current gradually decreases as the battery approaches full charge.

The absorption stage is crucial for ensuring that the battery is fully charged and that all the cells in the battery are balanced. This stage can take several hours, depending on the battery’s capacity and the charging current.

Float Stage

After the absorption stage, the battery is considered fully charged, and the charging process enters the float stage. In this stage, the charging voltage is lowered to a safe level (typically around 2.25 volts per cell) to maintain the battery’s charge and compensate for self-discharge.

The float stage prevents the battery from overcharging and helps to prolong its lifespan. The charging current in this stage is minimal, just enough to keep the battery topped off.

Importance of Proper Charging for Sealed Lead Acid Batteries

Proper charging is essential for the performance, longevity, and safety of sealed lead acid batteries. Overcharging, undercharging, or charging at excessive currents can lead to various problems, such as:

- Reduced battery capacity

- Shortened battery lifespan

- Overheating and thermal runaway

- Gassing and pressure build-up

- Risk of explosion or fire

To avoid these issues, it is crucial to use a well-designed battery charging circuit that adheres to the manufacturer’s specifications and incorporates the appropriate safety features, such as:

- Overvoltage protection

- Overcurrent protection

- Temperature monitoring and compensation

- Reverse polarity protection

By following best practices for charging sealed lead acid batteries and using a reliable charging circuit, you can ensure that your batteries perform optimally and last for many years.

Frequently Asked Questions (FAQ)

- What is the optimal charging voltage for a 12V sealed lead acid battery?

-

The optimal charging voltage for a 12V SLA battery is 2.25 to 2.30 volts per cell, which translates to 13.5 to 13.8 volts for the entire battery.

-

How long does it take to charge a sealed lead acid battery?

-

The charging time depends on the battery’s capacity and the charging current. A general rule of thumb is that it takes about 10 to 15 hours to fully charge an SLA battery at a charging current of 0.1C.

-

Can I use a higher charging current to charge my SLA battery faster?

-

While a higher charging current can indeed charge the battery faster, it is not recommended to exceed the manufacturer’s specified maximum charging current. Charging at excessive currents can lead to overheating, gassing, and reduced battery lifespan.

-

How often should I charge my sealed lead acid battery?

-

It is best to keep SLA batteries fully charged when not in use. If the battery is stored for an extended period, it should be charged every 3 to 6 months to prevent deep discharge and permanent capacity loss.

-

What should I do if my SLA battery overheats during charging?

- If you notice that your SLA battery is overheating during charging, immediately disconnect the charger and allow the battery to cool down. Overheating can be a sign of a faulty battery, a malfunctioning charger, or excessive charging current. If the problem persists, consult a professional or replace the battery.

Conclusion

Sealed lead acid battery charging circuits play a vital role in maintaining the health and performance of SLA batteries. By understanding the components and working principles of these circuits, you can design and implement efficient and safe charging systems for your applications.

Remember to always follow the manufacturer’s specifications, use appropriate safety features, and adhere to best practices when charging SLA batteries. With proper care and maintenance, your sealed lead acid batteries can provide reliable power for years to come.

No responses yet