Introduction to PCB Assembly

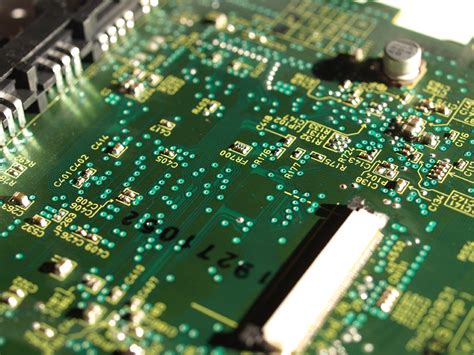

Printed Circuit Board (PCB) assembly is a crucial process in the manufacturing of electronic devices. It involves the placement and soldering of electronic components onto a printed circuit board, which serves as the backbone of the device. The PCB provides the electrical connections between components and enables the device to function as intended.

PCB assembly is a complex process that requires precision, accuracy, and attention to detail. It involves several steps, including component placement, soldering, inspection, and testing. The quality of the PCB assembly directly affects the performance, reliability, and durability of the electronic device.

In this article, we will provide a comprehensive overview of the PCB assembly process, including the different types of PCB assembly, the steps involved, and the equipment and techniques used. We will also discuss the advantages and disadvantages of each type of PCB assembly and provide tips for ensuring high-quality PCB assembly.

Types of PCB Assembly

There are two main types of PCB assembly: through-hole assembly and surface mount assembly.

Through-Hole Assembly

Through-hole assembly is the traditional method of PCB assembly. It involves inserting the leads of electronic components through holes drilled in the PCB and soldering them to the underside of the board. The components are typically larger and have longer leads than those used in surface mount assembly.

Advantages of through-hole assembly:

– Stronger mechanical bonds between components and the PCB

– Easier to replace or repair components

– Better for high-power applications

Disadvantages of through-hole assembly:

– Larger component size and lead length

– Higher cost and slower assembly process

– Limited component density on the PCB

Surface Mount Assembly

Surface mount assembly is a more modern method of PCB assembly. It involves placing electronic components directly onto the surface of the PCB and soldering them in place. The components are typically smaller and have shorter leads than those used in through-hole assembly.

Advantages of surface mount assembly:

– Smaller component size and lead length

– Higher component density on the PCB

– Faster assembly process and lower cost

– Better for high-frequency applications

Disadvantages of surface mount assembly:

– Weaker mechanical bonds between components and the PCB

– More difficult to replace or repair components

– Requires specialized equipment and skills

PCB Assembly Process

The PCB assembly process typically involves the following steps:

-

Solder Paste Application: Solder paste is applied to the PCB using a stencil or screen printing process. The solder paste contains tiny balls of solder that will melt and form the electrical connections between components and the PCB.

-

Component Placement: Electronic components are placed onto the PCB using a pick-and-place machine or by hand. The components are positioned according to the PCB design and held in place by the solder paste.

-

Reflow Soldering: The PCB is heated in a reflow oven, causing the solder paste to melt and form the electrical connections between components and the PCB. The temperature and duration of the reflow process are carefully controlled to ensure proper soldering.

-

Inspection: The PCB is inspected for any defects or errors in the assembly process. This may involve visual inspection, automated optical inspection (AOI), or X-ray inspection.

-

Testing: The PCB is tested to ensure that it functions as intended. This may involve functional testing, in-circuit testing, or boundary scan testing.

-

Cleaning: The PCB is cleaned to remove any residual flux or contaminants from the assembly process. This may involve using solvents or other cleaning agents.

-

Conformal Coating: A protective coating may be applied to the PCB to protect it from moisture, dust, and other environmental factors.

PCB Assembly Equipment and Techniques

PCB assembly requires specialized equipment and techniques to ensure high-quality results. Some of the key equipment and techniques used in PCB assembly include:

Stencil Printing

Stencil printing is a technique used to apply solder paste to the PCB. A stencil is a thin sheet of metal or plastic with openings that correspond to the pads on the PCB. The stencil is placed over the PCB, and solder paste is applied using a squeegee or automated printer.

Pick-and-Place Machines

Pick-and-place machines are automated systems that place electronic components onto the PCB. They use vacuum nozzles or grippers to pick up components from a feeder and place them onto the PCB with high precision and speed.

Reflow Ovens

Reflow ovens are used to melt the solder paste and form the electrical connections between components and the PCB. They use a controlled heating profile to ensure that the solder melts and flows properly without damaging the components or the PCB.

Automated Optical Inspection (AOI)

AOI systems use cameras and image processing software to inspect the PCB for defects or errors in the assembly process. They can detect issues such as missing or misaligned components, solder bridges, or insufficient solder joints.

X-Ray Inspection

X-ray inspection systems use X-rays to inspect the internal structure of the PCB and components. They can detect issues such as voids or cracks in solder joints, which may not be visible from the surface.

Advantages of PCB Assembly

PCB assembly offers several advantages over other methods of electronic device manufacturing, including:

-

Reduced Size and Weight: PCB assembly allows for smaller and lighter electronic devices by reducing the size and number of components and interconnections.

-

Increased Reliability: PCB assembly provides a more reliable and durable electronic device by reducing the number of interconnections and improving the mechanical and electrical properties of the device.

-

Improved Performance: PCB assembly can improve the performance of electronic devices by reducing signal distortion, crosstalk, and electromagnetic interference.

-

Lower Cost: PCB assembly can reduce the cost of electronic devices by automating the assembly process and reducing the number of components and interconnections required.

Challenges in PCB Assembly

Despite its many advantages, PCB assembly also presents several challenges, including:

-

Complexity: PCB assembly can be a complex process, especially for high-density or multi-layer boards. It requires specialized equipment, skills, and knowledge to ensure high-quality results.

-

Miniaturization: The trend towards miniaturization in electronic devices presents challenges for PCB assembly, as smaller components and tighter tolerances require more precise and accurate assembly processes.

-

Material Selection: The selection of materials for PCB assembly can be challenging, as different materials have different properties and requirements. The wrong material selection can lead to defects or failures in the electronic device.

-

Environmental Concerns: PCB assembly can have environmental impacts, such as the use of hazardous materials or the generation of waste. Manufacturers must comply with environmental regulations and standards to minimize these impacts.

Tips for High-Quality PCB Assembly

To ensure high-quality PCB assembly, manufacturers should follow these tips:

-

Design for Manufacturability: The PCB design should be optimized for manufacturability, with consideration for component placement, routing, and testability.

-

Use Appropriate Equipment and Techniques: Manufacturers should use appropriate equipment and techniques for PCB assembly, such as stencil printing, pick-and-place machines, and reflow ovens.

-

Implement Quality Control Measures: Manufacturers should implement quality control measures, such as inspection and testing, to detect and correct defects or errors in the assembly process.

-

Train and Certify Personnel: Manufacturers should train and certify their personnel in PCB assembly processes and techniques to ensure consistent and high-quality results.

-

Follow Industry Standards and Regulations: Manufacturers should follow industry standards and regulations for PCB assembly, such as IPC standards, to ensure compliance and quality.

Frequently Asked Questions (FAQ)

-

What is the difference between through-hole and surface mount assembly?

Through-hole assembly involves inserting component leads through holes in the PCB and soldering them to the underside of the board, while surface mount assembly involves placing components directly onto the surface of the PCB and soldering them in place. -

What are the advantages of surface mount assembly over through-hole assembly?

Surface mount assembly offers several advantages over through-hole assembly, including smaller component size, higher component density, faster assembly process, lower cost, and better performance for high-frequency applications. -

What are the key steps in the PCB assembly process?

The key steps in the PCB assembly process include solder paste application, component placement, reflow soldering, inspection, testing, cleaning, and conformal coating. -

What equipment is used in PCB assembly?

PCB assembly requires specialized equipment such as stencil printers, pick-and-place machines, reflow ovens, automated optical inspection systems, and X-ray inspection systems. -

What are some tips for ensuring high-quality PCB assembly?

Tips for ensuring high-quality PCB assembly include designing for manufacturability, using appropriate equipment and techniques, implementing quality control measures, training and certifying personnel, and following industry standards and regulations.

Conclusion

PCB assembly is a critical process in the manufacturing of electronic devices. It involves the placement and soldering of electronic components onto a printed circuit board, which serves as the backbone of the device. PCB assembly offers several advantages over other methods of electronic device manufacturing, including reduced size and weight, increased reliability, improved performance, and lower cost.

However, PCB assembly also presents several challenges, such as complexity, miniaturization, material selection, and environmental concerns. To ensure high-quality PCB assembly, manufacturers must follow best practices such as designing for manufacturability, using appropriate equipment and techniques, implementing quality control measures, training and certifying personnel, and following industry standards and regulations.

By understanding the different types of PCB assembly, the steps involved, and the equipment and techniques used, manufacturers can optimize their PCB assembly processes and produce high-quality electronic devices that meet the needs of their customers.

| PCB Assembly Type | Advantages | Disadvantages |

|---|---|---|

| Through-Hole Assembly | – Stronger mechanical bonds – Easier to replace or repair components – Better for high-power applications |

– Larger component size and lead length – Higher cost and slower assembly process – Limited component density |

| Surface Mount Assembly | – Smaller component size and lead length – Higher component density – Faster assembly process and lower cost – Better for high-frequency applications |

– Weaker mechanical bonds – More difficult to replace or repair components – Requires specialized equipment and skills |

No responses yet