Introduction to PCB Prototyping

Printed Circuit Board (PCB) prototyping is an essential step in the development of electronic devices. It allows designers and engineers to test and validate their designs before committing to full-scale production. In this article, we will explore the various options available for getting the fastest PCB Assembly prototype and provide insights on how to choose the best service provider for your needs.

Understanding the PCB Prototype Process

Before diving into the options for getting a PCB prototype, it’s important to understand the process involved. The PCB prototype process typically involves the following steps:

-

Design: The first step is to design the PCB using specialized software such as Altium, Eagle, or KiCad. The design includes the schematic, component placement, and routing of the traces.

-

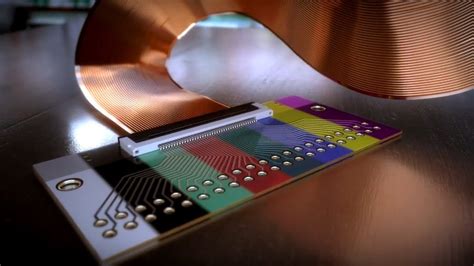

Fabrication: Once the design is finalized, the PCB is fabricated using a variety of methods such as etching, milling, or printing. The fabrication process involves creating the copper traces, drilling holes, and applying soldermask and silkscreen.

-

Assembly: After fabrication, the components are soldered onto the PCB. This can be done manually or using automated equipment such as pick-and-place machines and reflow ovens.

-

Testing: The assembLED PCB is then tested to ensure that it functions as intended. This may involve Functional Testing, boundary scan testing, or in-circuit testing.

Factors to Consider When Choosing a PCB Prototype Service

When choosing a PCB prototype service, there are several factors to consider:

Speed

One of the most important factors is speed. If you need your prototype quickly, you’ll want to choose a service that offers fast turnaround times. Some services can provide a prototype within 24 hours, while others may take several days or even weeks.

Quality

Another important factor is quality. You want to ensure that your prototype is fabricated and assembled to a high standard to avoid issues during testing and validation. Look for a service that uses high-quality materials and has a proven track record of delivering reliable prototypes.

Cost

Cost is also a consideration when choosing a PCB prototype service. While faster turnaround times and higher quality may come at a premium, it’s important to balance cost with your specific needs and budget.

Capabilities

Different PCB prototype services offer different capabilities. Some may specialize in certain types of PCBs such as high-density interconnect (HDI) or flexible PCBs, while others may offer a wider range of services. Consider your specific requirements when choosing a service.

Customer Support

Finally, customer support is an important factor to consider. Look for a service that offers responsive and knowledgeable support to help you through the prototyping process and address any issues that may arise.

Options for Getting a PCB Prototype

There are several options available for getting a PCB prototype, each with its own advantages and disadvantages.

In-House Prototyping

If you have the necessary equipment and expertise, you can prototype your PCB in-house. This allows for greater control over the process and can be faster and more cost-effective than outsourcing. However, it requires a significant investment in equipment and may not be feasible for all companies.

Local Prototyping Services

Another option is to use a local prototyping service. These services often offer faster turnaround times and more personalized service than online options. However, they may be more expensive and have limited capabilities compared to larger online services.

Online Prototyping Services

Online prototyping services are a popular option for getting a PCB prototype. These services offer a wide range of capabilities and can often provide faster turnaround times and lower costs than local options. Some popular online prototyping services include:

| Service | Capabilities | Turnaround Time | Cost |

|---|---|---|---|

| PCBWay | PCB fabrication, assembly, and testing | 24 hours for fabrication, 3-5 days for assembly | $5 for 10 PCBs, assembly starting at $30 |

| JLCPCB | PCB fabrication, assembly, and testing | 24 hours for fabrication, 3-5 days for assembly | $2 for 10 PCBs, assembly starting at $8 |

| Seeed Studio Fusion | PCB fabrication, assembly, and testing | 5 days for fabrication, 7 days for assembly | $4.90 for 10 PCBs, assembly starting at $8.50 |

When choosing an online prototyping service, consider their capabilities, turnaround times, and cost to find the best fit for your needs.

Specialized Prototyping Services

For more complex or specialized PCBs, you may need to use a specialized prototyping service. These services offer expertise in specific areas such as High-Frequency PCBs, flexible PCBs, or PCBs for harsh environments. They may have longer turnaround times and higher costs than general prototyping services, but can provide the necessary expertise for challenging projects.

Tips for a Successful PCB Prototype

To ensure a successful PCB prototype, consider the following tips:

-

Start with a clear and detailed design: Ensure that your design is complete and accurate before sending it for prototyping. This will help avoid delays and issues during fabrication and assembly.

-

Choose the right service for your needs: Consider your specific requirements for speed, quality, cost, and capabilities when choosing a prototyping service.

-

Communicate clearly with your service provider: Provide clear instructions and communicate any special requirements or concerns to your service provider to ensure that your prototype meets your expectations.

-

Test thoroughly: Once you receive your prototype, test it thoroughly to ensure that it functions as intended. This will help identify any issues early in the development process and avoid costly mistakes down the line.

Frequently Asked Questions

How long does it take to get a PCB prototype?

The turnaround time for a PCB prototype varies depending on the service provider and the complexity of the design. Some services can provide a prototype within 24 hours, while others may take several days or even weeks.

How much does a PCB prototype cost?

The cost of a PCB prototype varies depending on the service provider, the complexity of the design, and the quantity ordered. Basic PCB fabrication can start at just a few dollars for small quantities, while more complex designs and larger quantities will be more expensive. Assembly costs will also vary depending on the number and type of components used.

What files do I need to provide for PCB prototyping?

To get a PCB prototype, you will typically need to provide the following files:

- Gerber files: These are the files that define the copper traces, soldermask, and silkscreen for the PCB.

- Drill files: These specify the location and size of the holes to be drilled in the PCB.

- Bill of Materials (BOM): This is a list of all the components used in the design, including their part numbers and quantities.

- Assembly files: These provide instructions for assembling the components onto the PCB, such as the pick-and-place file and the centroid file.

Can I get a PCB prototype without assembly?

Yes, most PCB prototyping services offer the option to get just the bare PCB fabricated without assembly. This can be a good option if you have the capability to assemble the components yourself or if you just need the bare PCB for testing purposes.

What are the benefits of PCB prototyping?

PCB prototyping offers several benefits for the development of electronic devices, including:

- Validation: Prototyping allows you to test and validate your design before committing to full-scale production, helping to identify any issues early in the development process.

- Iteration: Prototyping enables rapid iteration and refinement of your design, allowing you to make changes and improvements quickly and easily.

- Cost savings: By identifying and addressing issues early in the development process, prototyping can help avoid costly mistakes and rework down the line.

- Time to market: Prototyping can help accelerate the development process and bring your product to market faster by enabling parallel development and testing.

Conclusion

PCB prototyping is a critical step in the development of electronic devices, allowing designers and engineers to test and validate their designs before committing to full-scale production. When choosing a PCB prototype service, consider factors such as speed, quality, cost, capabilities, and customer support to find the best fit for your needs. By following best practices and working closely with your chosen service provider, you can ensure a successful PCB prototype and bring your product to market faster and with greater confidence.

No responses yet