Introduction to PCB-History

Printed Circuit Boards (PCBs) have revolutionized the electronics industry since their inception in the early 20th century. The development of PCBs has enabled the miniaturization and mass production of electronic devices, making them more affordable and accessible to consumers worldwide. In this article, we will delve into the fascinating history of PCBs, exploring their origin, evolution, and impact on modern technology.

The Birth of PCBs: Early Developments

Albert Hanson’s Flat Foil Conductors

The concept of PCBs can be traced back to 1903 when German inventor Albert Hanson filed a patent for a device that used flat foil conductors laminated to an insulating board. Although Hanson’s invention was not a true PCB, it laid the groundwork for future developments in the field.

Paul Eisler’s Printed Circuits

In 1936, Austrian engineer Paul Eisler invented the first true PCB while working on a radio set. Eisler’s design consisted of a network of copper foil traces bonded to a non-conductive substrate, which served as the foundation for modern PCBs. However, due to the outbreak of World War II, Eisler’s invention did not gain widespread recognition until the 1950s.

The Rise of PCBs in the 1940s and 1950s

World War II and PCB Adoption

During World War II, the demand for reliable and compact electronic equipment for military applications skyrocketed. This led to the adoption of PCBs in various military projects, such as the proximity fuse for artillery shells and the Colossus computer used for decrypting German messages.

Post-War Commercialization

After the war, PCBs began to gain traction in the commercial sector. In 1948, the United States released the invention for public use, and companies like Hazeltyne and Motorola started mass-producing PCBs for consumer electronics, such as televisions and radios.

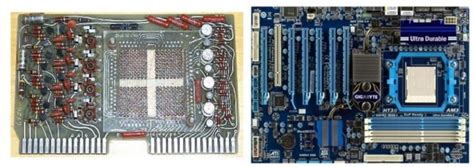

PCB Manufacturing Techniques: Evolution and Advancements

Through-Hole Technology

Early PCBs utilized through-hole technology, where component leads were inserted into drilled holes and soldered to copper traces on the other side of the board. This method was reliable but limited the component density and required manual assembly.

Surface Mount Technology (SMT)

In the 1960s, Surface Mount Technology (SMT) was developed, allowing components to be directly soldered onto the surface of the PCB. SMT enabled higher component density, automation of the assembly process, and reduced Manufacturing costs. By the 1980s, SMT had become the dominant PCB Assembly method.

Multilayer PCBs

As electronic devices became more complex, the need for higher circuit density and better signal integrity arose. Multilayer PCBs, which consist of multiple layers of copper traces separated by insulating material, were developed to meet these requirements. Multilayer PCBs allowed for more compact designs and improved electromagnetic interference (EMI) shielding.

The Digital Age and Beyond

The Rise of Personal Computers and Consumer Electronics

The 1970s and 1980s saw the emergence of personal computers and a boom in consumer electronics. PCBs played a crucial role in the development of these devices, enabling the creation of compact and affordable products like the Apple II and the Sony Walkman.

PCBs in the Age of the Internet and Mobile Devices

The advent of the internet and mobile devices in the 1990s and 2000s brought about a new era of PCB design and manufacturing. High-speed PCBs were developed to accommodate the increasing data transfer rates required by these technologies. Additionally, the demand for smaller, lighter, and more power-efficient devices drove the development of advanced PCB materials and manufacturing techniques, such as High-Density Interconnect (HDI) PCBs and flexible PCBs.

Current Trends and Future Prospects

PCBs in the Internet of Things (IoT) Era

The Internet of Things (IoT) has emerged as a major trend in recent years, with the proliferation of connected devices in various sectors, including healthcare, automotive, and home automation. PCBs play a vital role in enabling IoT devices, providing the necessary connectivity, processing power, and sensor integration.

Sustainable and Eco-Friendly PCB Manufacturing

As environmental concerns grow, there is an increasing focus on sustainable and eco-friendly PCB manufacturing practices. This includes the use of lead-free solder, halogen-free materials, and the adoption of green manufacturing processes that minimize waste and energy consumption.

Future Advancements in PCB Technology

The future of PCBs looks promising, with ongoing research and development in areas such as embedded components, 3D printing of PCBs, and the use of advanced materials like graphene and carbon nanotubes. These advancements aim to further improve the performance, reliability, and sustainability of PCBs.

Conclusion

The history of PCBs is a testament to human ingenuity and the relentless pursuit of technological advancement. From their humble beginnings in the early 20th century to their ubiquitous presence in modern electronics, PCBs have undergone a remarkable journey. As we look towards the future, it is clear that PCBs will continue to play a vital role in shaping the electronic landscape, enabling the development of new and innovative technologies that will transform our world.

Frequently Asked Questions (FAQ)

1. Who invented the first printed circuit board?

Austrian engineer Paul Eisler invented the first true printed circuit board in 1936 while working on a radio set.

2. How did World War II impact the development of PCBs?

During World War II, the demand for reliable and compact electronic equipment for military applications led to the adoption of PCBs in various military projects, such as the proximity fuse for artillery shells and the Colossus computer used for decrypting German messages.

3. What is the difference between through-hole technology and surface mount technology (SMT)?

Through-hole technology involves inserting component leads into drilled holes and soldering them to copper traces on the other side of the board. SMT, on the other hand, allows components to be directly soldered onto the surface of the PCB, enabling higher component density and automated assembly.

4. What are multilayer PCBs, and why are they important?

Multilayer PCBs consist of multiple layers of copper traces separated by insulating material. They were developed to meet the need for higher circuit density and better signal integrity in complex electronic devices. Multilayer PCBs allow for more compact designs and improved electromagnetic interference (EMI) shielding.

5. How are PCBs contributing to the development of the Internet of Things (IoT)?

PCBs play a vital role in enabling IoT devices by providing the necessary connectivity, processing power, and sensor integration. As the IoT continues to grow, PCBs will remain crucial in the development of connected devices across various sectors, including healthcare, automotive, and home automation.

| Era | Key Developments |

|---|---|

| Early 20th Century | – Albert Hanson’s flat foil conductors (1903) – Paul Eisler’s printed circuits (1936) |

| 1940s-1950s | – Adoption of PCBs in military projects during World War II – Post-war commercialization of PCBs in consumer electronics |

| 1960s-1980s | – Development of Surface Mount Technology (SMT) – Emergence of multilayer PCBs |

| 1990s-2000s | – PCBs in the age of the internet and mobile devices – Development of high-speed PCBs and advanced manufacturing techniques |

| Current and Future | – PCBs in the Internet of Things (IoT) era – Focus on sustainable and eco-friendly PCB manufacturing – Ongoing research and development in embedded components, 3D printing, and advanced materials |

No responses yet