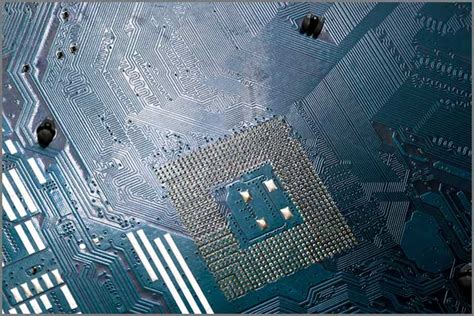

What is PCB?

PCB stands for Printed Circuit Board. It is a flat board made of insulating material, such as fiberglass or composite epoxy, with conductive copper traces etched onto its surface. PCBs are used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces.

Types of PCBs

There are several types of PCBs, including:

- Single-sided PCB: Components are placed on one side of the board, and the other side has copper traces.

- Double-sided PCB: Both sides of the board have components and copper traces.

- Multi-layer PCB: The board consists of multiple layers of conductive material separated by insulating layers.

- Flexible PCB: Made from flexible plastic materials, allowing the board to bend and fit into tight spaces.

- Rigid-Flex PCB: A combination of rigid and flexible PCBs, offering both stability and flexibility.

Applications of PCBs

PCBs are used in a wide range of electronic devices, such as:

- Computers and laptops

- Smartphones and tablets

- Televisions and home appliances

- Automotive electronics

- Medical devices

- Industrial equipment

What is PCBA?

PCBA stands for Printed Circuit Board Assembly. It is the process of assembling electronic components onto a PCB to create a functional electronic device. PCBA involves soldering components, such as resistors, capacitors, and integrated circuits, onto the PCB according to a specific design.

PCBA Process

The PCBA process typically involves the following steps:

- Solder Paste Application: Solder paste is applied to the PCB pads using a stencil or screen printing process.

- Component Placement: Electronic components are placed onto the PCB using pick-and-place machines or by hand.

- Reflow Soldering: The PCB is heated in a reflow oven, melting the solder paste and creating a permanent connection between the components and the PCB.

- Inspection: The assembLED PCB is inspected for defects, such as missing components, shorts, or poor solder joints.

- Testing: The PCBA undergoes Functional Testing to ensure it meets the required specifications and performance criteria.

Advantages of PCBA

PCBA offers several advantages, including:

- Increased reliability and consistency compared to hand-soldered assemblies

- Faster production times and higher throughput

- Ability to handle smaller components and higher component densities

- Improved quality control and reduced human error

PCB vs PCBA: Key Differences

| Aspect | PCB | PCBA |

|---|---|---|

| Definition | A bare board with conductive traces | An assembled board with components |

| Components | No components attached | Components soldered onto the PCB |

| Functionality | Not functional on its own | Fully functional electronic device |

| Design Focus | Layout and routing of traces | Component selection and placement |

| Manufacturing Process | Etching, drilling, and plating | Solder paste application, component placement, and reflow soldering |

| Testing | Continuity and isolation tests | Functional and performance tests |

| Cost | Lower cost compared to PCBA | Higher cost due to additional components and assembly |

| Lead Time | Shorter lead times | Longer lead times due to assembly process |

Frequently Asked Questions (FAQ)

1. Can a PCB function without components?

No, a PCB is merely a substrate with conductive traces. It requires electronic components to be assembled onto it to function as an electronic device.

2. Is it possible to reuse a PCBA in another device?

In most cases, a PCBA is designed for a specific device and may not be compatible with other devices. However, some standardized PCBAs, such as Arduino boards, can be used in multiple projects.

3. What is the difference between through-hole and surface-mount components?

Through-hole components have leads that are inserted into holes drilled in the PCB and soldered on the opposite side. Surface-mount components are placed directly onto the PCB pads and soldered in place.

4. How can I ensure the quality of my PCBA?

To ensure the quality of your PCBA, work with reputable manufacturers, use high-quality components, and implement strict quality control measures, such as automated optical inspection (AOI) and functional testing.

5. What factors influence the cost of a PCBA?

The cost of a PCBA depends on several factors, including the complexity of the design, the number and type of components, the PCB material and size, the quantity ordered, and the assembly process required.

Conclusion

Understanding the difference between PCB and PCBA is crucial for anyone involved in electronic product development. While a PCB is the foundation of an electronic device, providing a platform for interconnecting components, a PCBA is the fully assembled and functional unit.

When designing and manufacturing an electronic device, it is essential to consider both the PCB layout and the PCBA process to ensure optimal performance, reliability, and cost-effectiveness. By working with experienced PCB designers and PCBA manufacturers, you can bring your electronic product ideas to life and create high-quality, competitive devices.

As technology continues to advance, the importance of PCBs and PCBAs will only continue to grow. Staying informed about the latest developments in PCB and PCBA technologies, materials, and processes will help you stay ahead of the curve and create innovative electronic solutions for a wide range of applications.

No responses yet