Understanding Panelization dimensions

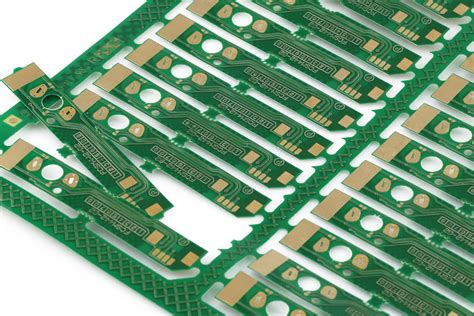

Panelization is a process in PCB manufacturing where multiple printed circuit boards (PCBs) are grouped together on a single panel for efficient fabrication and assembly. This approach helps to reduce manufacturing costs, streamline the production process, and minimize material waste. When designing panels for PCB production, it is crucial to consider the dimensions of the individual boards, the spacing between them, and the inclusion of breakaway tabs or mouse bites for easy separation.

Key Factors in Panelization Dimensions

- PCB dimensions

- Length and width of the individual PCBs

- Thickness of the PCB substrate

-

Number of layers in the PCB stack-up

-

Panel Dimensions

- Overall size of the panel (length and width)

- Maximum allowable panel size based on manufacturing equipment limitations

-

Minimum required border around the panel edges

-

Spacing Between PCBs

- Distance between adjacent PCBs on the panel

-

Minimum spacing requirements to ensure proper separation and avoid damage during depaneling

-

Breakaway Tabs and Mouse Bites

- Size and shape of the breakaway tabs or mouse bites

- Placement and distribution of tabs or bites along the PCB edges

- Strength and durability of the tabs or bites to withstand the depaneling process

Determining PCB Dimensions

The first step in panelization is to determine the dimensions of the individual PCBs that will be included on the panel. These dimensions are based on the specific design requirements of the electronic device or system being developed.

PCB Length and Width

The length and width of the PCB are determined by the size and placement of the components, connectors, and other features that need to be accommodated on the board. It is important to consider the following factors when determining the PCB dimensions:

- Component footprints and their arrangement on the board

- Routing space required for signal traces and power planes

- Clearance requirements around components and board edges

- Mechanical constraints imposed by the device enclosure or mounting points

PCB Thickness

The thickness of the PCB is determined by the number of layers in the PCB stack-up and the thickness of the individual layers. Common PCB thicknesses include:

| Number of Layers | Typical Thickness (mm) |

|---|---|

| 1 | 0.4 – 0.8 |

| 2 | 0.8 – 1.6 |

| 4 | 1.0 – 2.0 |

| 6 | 1.2 – 2.4 |

| 8 | 1.6 – 3.2 |

The choice of PCB thickness depends on the electrical and mechanical requirements of the design, such as signal integrity, power handling capacity, and structural rigidity.

PCB Stack-up

The number of layers in the PCB stack-up is determined by the complexity of the circuit design and the routing requirements. A typical PCB stack-up may include the following layers:

- Top and bottom copper layers for component placement and signal routing

- Inner copper layers for power and ground planes, as well as additional signal routing

- Dielectric layers to provide insulation between the copper layers

- Solder mask layers to protect the copper traces and prevent short circuits

- Silkscreen layers for component labels and other markings

The specific arrangement and thickness of the layers in the stack-up can vary depending on the design requirements and the PCB manufacturer’s capabilities.

Determining Panel Dimensions

Once the dimensions of the individual PCBs have been established, the next step is to determine the overall dimensions of the panel that will accommodate multiple PCBs.

Maximum Panel Size

The maximum panel size is typically determined by the limitations of the manufacturing equipment used in the PCB fabrication process. Common panel sizes include:

| Panel Size | Dimensions (mm) |

|---|---|

| Standard (S) | 457 x 305 |

| Large (L) | 508 x 406 |

| Extra Large (XL) | 610 x 457 |

It is important to consult with the PCB manufacturer to determine the maximum panel size they can accommodate and any specific requirements they may have for panel design.

Minimum Border Requirements

In addition to the maximum panel size, there are also minimum border requirements that must be considered when designing the panel layout. The border is the area around the perimeter of the panel that is used for handling, tooling, and other manufacturing processes.

The minimum border size can vary depending on the PCB manufacturer and the specific fabrication processes being used. Typical border requirements range from 5mm to 10mm on each side of the panel.

Spacing Between PCBs

The spacing between adjacent PCBs on the panel is a critical factor in panelization design. Adequate spacing is necessary to ensure that the individual boards can be easily separated from the panel without damage and to accommodate any tooling or handling requirements during the manufacturing process.

Minimum Spacing Requirements

The minimum spacing between PCBs is typically determined by the capabilities of the PCB manufacturer and the specific fabrication processes being used. Common minimum spacing requirements include:

| Process | Minimum Spacing (mm) |

|---|---|

| V-scoring | 1.0 – 1.5 |

| Tab routing | 1.5 – 2.0 |

| Mouse bites | 0.5 – 1.0 |

It is important to consult with the PCB manufacturer to determine their specific spacing requirements and to ensure that the panel design complies with their guidelines.

Spacing Considerations

In addition to the minimum spacing requirements, there are several other factors that should be considered when determining the spacing between PCBs on the panel:

- Depaneling method: The spacing requirements may vary depending on the method used to separate the individual PCBs from the panel (e.g., v-scoring, tab routing, or mouse bites).

- PCB thickness: Thicker PCBs may require slightly larger spacing to accommodate the depaneling process and prevent damage to the boards.

- Component clearance: The spacing should be sufficient to ensure that components near the edges of the PCBs are not damaged during the depaneling process.

- Panelization efficiency: While larger spacing between PCBs may be easier to manufacture, it can also reduce the number of PCBs that can fit on a single panel, affecting the overall production efficiency.

Breakaway Tabs and Mouse Bites

Breakaway tabs and mouse bites are features that are incorporated into the panel design to facilitate the separation of individual PCBs from the panel. These features provide a controlled and predictable way to break the PCBs away from the panel without causing damage to the boards or components.

Breakaway Tabs

Breakaway tabs are small, rectangular protrusions that are added to the edges of the PCBs on the panel. These tabs are typically made from the same material as the PCB substrate and are designed to be easily broken off after the manufacturing process is complete.

The size and shape of the breakaway tabs can vary depending on the specific design requirements and the capabilities of the PCB manufacturer. Common tab dimensions include:

| Tab Parameter | Typical Dimension (mm) |

|---|---|

| Length | 3.0 – 5.0 |

| Width | 1.5 – 3.0 |

| Height | Same as PCB thickness |

The number and placement of breakaway tabs along the PCB edges should be determined based on the size and shape of the individual boards, as well as the depaneling method being used. Typically, tabs are placed at the corners of the PCBs and at regular intervals along the edges to ensure even distribution of the breaking force.

Mouse Bites

Mouse bites, also known as nibble cuts or perforation cuts, are small, semi-circular cutouts that are made along the edges of the PCBs on the panel. These cuts create a perforated line between adjacent PCBs, allowing them to be easily separated by breaking along the line of mouse bites.

The size and spacing of the mouse bites can vary depending on the specific design requirements and the capabilities of the PCB manufacturer. Common mouse bite dimensions include:

| Mouse Bite Parameter | Typical Dimension (mm) |

|---|---|

| Diameter | 0.5 – 1.0 |

| Pitch (center-to-center spacing) | 1.0 – 2.0 |

The number and placement of mouse bites along the PCB edges should be determined based on the size and shape of the individual boards, as well as the required strength of the connection between the PCBs during the manufacturing process. A larger number of mouse bites will result in a weaker connection, making it easier to separate the boards, but may also increase the risk of accidental separation during handling.

Choosing Between Breakaway Tabs and Mouse Bites

The choice between using breakaway tabs or mouse bites for panelization depends on several factors, including:

- PCB thickness: Breakaway tabs are generally more suitable for thicker PCBs (1.6mm or greater), while mouse bites are often used for thinner PCBs (less than 1.6mm).

- Depaneling equipment: The availability and capabilities of the depaneling equipment used by the PCB manufacturer may influence the choice between tabs and mouse bites.

- Design requirements: The specific design requirements of the PCBs, such as the presence of components or connectors near the board edges, may dictate the use of one method over the other.

- Manufacturing cost: The cost of implementing breakaway tabs or mouse bites can vary depending on the specific design and the PCB manufacturer’s capabilities.

It is important to consult with the PCB manufacturer to determine the most suitable method for your specific project and to ensure that the panel design meets their requirements.

Designing the Panel Layout

Once the dimensions of the individual PCBs, the panel size, and the spacing and breakaway features have been determined, the next step is to design the panel layout. The panel layout should be designed to maximize the number of PCBs that can fit on a single panel while ensuring that all manufacturing and design requirements are met.

Panel Utilization

Panel utilization is a measure of how efficiently the available panel space is being used. A higher panel utilization means that more PCBs can be produced from a single panel, reducing material waste and manufacturing costs.

To maximize panel utilization, consider the following strategies:

-

Optimize PCB orientation: Arrange the PCBs on the panel in a way that minimizes the amount of unused space between boards. This may involve rotating the PCBs or adjusting their placement to achieve a tighter fit.

-

Use mixed PCB Sizes: If your project involves PCBs of different sizes, consider combining them on a single panel to maximize the use of available space. This can be especially effective when the PCBs have similar thickness and material requirements.

-

Minimize border size: While it is important to maintain the minimum required border size, reducing the border dimensions can help to increase the number of PCBs that can fit on a panel.

-

Optimize spacing: Use the minimum allowable spacing between PCBs to maximize the number of boards that can fit on the panel. However, be sure to maintain enough space to ensure reliable depaneling and to prevent damage to the boards or components.

Panelization Software

To aid in the design of the panel layout, many PCB design software packages include panelization tools that can automatically generate panel layouts based on the dimensions of the individual PCBs and the specified manufacturing requirements.

These tools typically provide features such as:

- Automatic placement of PCBs on the panel

- Optimization of panel utilization

- Generation of breakaway tabs or mouse bites

- Addition of tooling holes and fiducial markers

- Creation of detailed panel drawings and manufacturing files

Using panelization software can help to streamline the panel design process, reduce the risk of errors, and ensure that the final panel layout meets all manufacturing requirements.

Conclusion

Panelization is a critical aspect of PCB manufacturing that requires careful consideration of the dimensions and layout of both the individual PCBs and the overall panel. By understanding the key factors involved in panelization, such as PCB size, panel dimensions, spacing requirements, and breakaway features, designers can create panel layouts that are optimized for manufacturing efficiency and cost-effectiveness.

When designing panels for PCB production, it is essential to work closely with the PCB manufacturer to ensure that the panel layout meets their specific requirements and capabilities. By following best practices for panelization and leveraging the tools and expertise available, designers can help to ensure the success of their PCB projects and bring their electronic products to market more quickly and efficiently.

Frequently Asked Questions (FAQ)

-

What is the purpose of panelization in PCB manufacturing?

Panelization is used to group multiple PCBs together on a single panel for efficient fabrication and assembly. This approach helps to reduce manufacturing costs, streamline the production process, and minimize material waste. -

What factors should be considered when determining the spacing between PCBs on a panel?

The spacing between PCBs should be determined based on the minimum requirements of the PCB manufacturer, the depaneling method being used, the thickness of the PCBs, and the clearance required for components near the board edges. It is important to strike a balance between manufacturing efficiency and the need for reliable depaneling without damaging the boards or components. -

What are the differences between breakaway tabs and mouse bites?

Breakaway tabs are small, rectangular protrusions added to the edges of the PCBs on the panel, designed to be easily broken off after manufacturing. Mouse bites, on the other hand, are small, semi-circular cutouts made along the edges of the PCBs, creating a perforated line for easy separation. Breakaway tabs are generally more suitable for thicker PCBs, while mouse bites are often used for thinner PCBs. -

How can panel utilization be maximized in panelization design?

To maximize panel utilization, designers can optimize the orientation and placement of PCBs on the panel, use mixed PCB sizes to fill available space, minimize border sizes, and optimize the spacing between boards. Using panelization software can also help to automatically generate efficient panel layouts based on the specified design and manufacturing requirements. -

Why is it important to consult with the PCB manufacturer when designing panels for production?

PCB manufacturers have specific requirements and capabilities that can impact the design of the panel layout, such as maximum panel sizes, minimum border dimensions, and spacing requirements for different depaneling methods. Consulting with the manufacturer helps to ensure that the panel design is compatible with their production processes and can be efficiently fabricated and assembled. This collaboration can help to avoid design issues, reduce manufacturing costs, and improve the overall quality and reliability of the final PCBs.

No responses yet