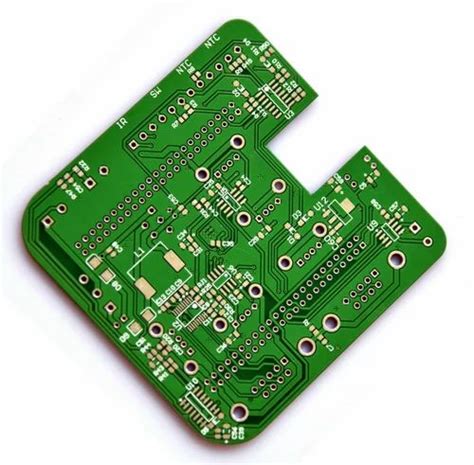

Introduction to High Tg PCBs and RF4 PCBs

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and supporting various components. As technology advances and demands for high-performance materials increase, the need for specialized PCBs with enhanced properties has grown significantly. One such category of PCBs is high Tg (glass transition temperature) PCBs, which offer superior thermal stability and mechanical strength. Among the different types of high Tg PCBs, RF4 PCBs have gained popularity due to their excellent electrical properties and ability to withstand extreme conditions.

What are High Tg PCBs?

High Tg PCBs are printed circuit boards that are manufactured using materials with a high glass transition temperature (Tg). The glass transition temperature is the point at which a material transitions from a hard, glassy state to a soft, rubbery state. In the context of PCBs, a higher Tg value indicates that the material can maintain its structural integrity and mechanical properties at elevated temperatures.

Typically, high Tg PCBs have a Tg value of 170°C or higher. This enhanced thermal stability makes them suitable for applications that involve exposure to high temperatures, such as automotive electronics, aerospace systems, and industrial equipment.

Understanding RF4 PCBs

RF4 PCBs are a specific type of high Tg PCB that utilizes a laminate material known as RF-4. RF-4 is a glass-reinforced epoxy laminate that exhibits excellent electrical properties, making it ideal for high-frequency and high-speed applications. The key characteristics of RF4 PCBs include:

-

Low dielectric constant (Dk): RF-4 has a low dielectric constant, typically around 4.3 at 1 MHz, which minimizes signal loss and ensures faster signal propagation.

-

Low dissipation factor (Df): The dissipation factor of RF-4 is low, usually around 0.02 at 1 MHz, resulting in reduced signal attenuation and improved signal integrity.

-

High thermal stability: RF-4 has a high Tg value, typically ranging from 170°C to 180°C, ensuring that the PCB can withstand elevated temperatures without compromising its performance.

-

Excellent mechanical strength: The glass reinforcement in RF-4 provides enhanced mechanical strength and durability, making it resistant to vibration, shock, and other physical stresses.

Benefits of Using High Tg PCBs and RF4 PCBs

Thermal Stability

One of the primary benefits of using high Tg PCBs, including RF4 PCBs, is their exceptional thermal stability. With a Tg value of 170°C or higher, these PCBs can maintain their structural integrity and performance even when subjected to high temperatures. This thermal stability is crucial in applications where the PCB is exposed to extreme heat, such as in automotive engine control units, power electronics, and industrial equipment.

Mechanical Strength and Durability

High Tg PCBs, particularly RF4 PCBs, exhibit excellent mechanical strength and durability. The glass reinforcement in the RF-4 laminate provides a robust structure that can withstand various physical stresses, including vibration, shock, and impact. This enhanced durability ensures the longevity and reliability of the PCB, reducing the risk of failure and minimizing maintenance requirements.

Improved Electrical Performance

RF4 PCBs are renowned for their superior electrical properties, making them an ideal choice for high-frequency and high-speed applications. The low dielectric constant and low dissipation factor of RF-4 contribute to reduced signal loss, faster signal propagation, and improved signal integrity. These characteristics are essential in applications such as telecommunications, radar systems, and high-speed digital circuits, where signal quality and timing are critical.

Wide Range of Tg Options

One of the advantages of working with a high Tg PCB manufacturer is the availability of RF4 PCBs with a wide range of Tg values. While the typical Tg range for RF4 PCBs is between 170°C and 180°C, some manufacturers offer RF4 PCBs with Tg values as high as 200°C or more. This flexibility allows designers to select the most suitable Tg value based on the specific requirements of their application, ensuring optimal performance and reliability.

Applications of High Tg PCBs and RF4 PCBs

Automotive Electronics

The automotive industry is a significant consumer of high Tg PCBs, including RF4 PCBs. Modern vehicles are equipped with numerous electronic systems, such as engine control units (ECUs), infotainment systems, and advanced driver assistance systems (ADAS). These systems often operate in harsh environments, exposed to high temperatures, vibration, and moisture. High Tg PCBs provide the necessary thermal stability and mechanical strength to withstand these conditions, ensuring reliable performance and long-term durability.

Aerospace and Defense

Aerospace and defense applications demand PCBs that can operate in extreme conditions, including high altitudes, wide temperature ranges, and exposure to radiation. High Tg PCBs, particularly RF4 PCBs, are well-suited for these demanding environments. Their thermal stability, mechanical strength, and excellent electrical properties make them reliable choices for avionics, satellite communication systems, radar equipment, and military electronics.

Industrial Equipment

Industrial equipment, such as power converters, motor drives, and process control systems, often operates in challenging environments with elevated temperatures and exposure to vibration and shock. High Tg PCBs, including RF4 PCBs, provide the necessary thermal stability and mechanical robustness to withstand these conditions. Their ability to maintain performance and reliability in harsh industrial settings makes them a preferred choice for manufacturers of industrial electronics.

Telecommunications and Networking

RF4 PCBs are widely used in telecommunications and networking applications due to their excellent electrical properties. The low dielectric constant and low dissipation factor of RF-4 make it an ideal material for high-frequency and high-speed circuits, such as RF modules, wireless communication devices, and high-speed networking equipment. RF4 PCBs ensure minimal signal loss, faster signal propagation, and improved signal integrity, enabling reliable and efficient data transmission.

Choosing the Right High Tg PCB Manufacturer

When selecting a high Tg PCB manufacturer, several factors should be considered to ensure the best quality and service. Here are some key points to keep in mind:

-

Experience and Expertise: Look for a manufacturer with extensive experience in producing high Tg PCBs, particularly RF4 PCBs. They should have a proven track record of delivering high-quality products and demonstrating expertise in PCB manufacturing processes.

-

Quality Control and Certifications: Choose a manufacturer that adheres to strict quality control standards and holds relevant certifications, such as ISO 9001, IATF 16949, and UL. These certifications indicate that the manufacturer follows established quality management systems and meets industry standards.

-

Technical Support and Customer Service: A reliable high Tg PCB manufacturer should provide excellent technical support and customer service. They should be responsive to inquiries, offer design assistance, and provide timely feedback to ensure a smooth collaboration throughout the manufacturing process.

-

Customization Options: Opt for a manufacturer that offers customization options to meet your specific requirements. They should be able to provide RF4 PCBs with different Tg values, layer counts, and other specifications tailored to your application needs.

-

Lead Time and Delivery: Consider the manufacturer’s lead time and delivery capabilities. They should have efficient production processes and a reliable supply chain to ensure timely delivery of your PCBs, minimizing any potential delays in your project timeline.

Frequently Asked Questions (FAQ)

-

What is the typical Tg range for RF4 PCBs?

The typical Tg range for RF4 PCBs is between 170°C and 180°C. However, some manufacturers offer RF4 PCBs with Tg values as high as 200°C or more, providing even greater thermal stability. -

Can RF4 PCBs be used for high-frequency applications?

Yes, RF4 PCBs are well-suited for high-frequency applications due to their low dielectric constant and low dissipation factor. These properties minimize signal loss and ensure faster signal propagation, making RF4 PCBs ideal for applications such as telecommunications, radar systems, and wireless communication devices. -

Are high Tg PCBs more expensive than standard PCBs?

Yes, high Tg PCBs, including RF4 PCBs, are generally more expensive than standard PCBs due to the specialized materials and manufacturing processes involved. However, the enhanced thermal stability, mechanical strength, and electrical properties offered by high Tg PCBs justify the added cost for applications that require superior performance and reliability. -

How do I choose the right Tg value for my RF4 PCB?

The choice of Tg value for your RF4 PCB depends on the specific requirements of your application. Factors to consider include the operating temperature range, environmental conditions, and the level of thermal stability required. Consult with your high Tg PCB manufacturer to determine the most suitable Tg value based on your application needs. -

What certifications should I look for when selecting a high Tg PCB manufacturer?

When selecting a high Tg PCB manufacturer, look for certifications such as ISO 9001 (quality management), IATF 16949 (automotive quality management), and UL (safety and performance standards). These certifications indicate that the manufacturer adheres to strict quality control processes and meets industry standards, ensuring the reliability and consistency of their products.

Conclusion

High Tg PCBs, particularly RF4 PCBs, offer numerous benefits for applications that demand superior thermal stability, mechanical strength, and electrical performance. With their ability to withstand elevated temperatures, resist physical stresses, and maintain signal integrity, RF4 PCBs are widely used in industries such as automotive, aerospace, industrial equipment, and telecommunications.

When choosing a high Tg PCB manufacturer, it is essential to consider factors such as experience, quality control, technical support, customization options, and delivery capabilities. By partnering with a reliable manufacturer that offers RF4 PCBs with a wide range of Tg values, you can ensure that your PCBs meet the specific requirements of your application, delivering optimal performance and reliability.

As technology continues to advance and the demand for high-performance electronics grows, the importance of high Tg PCBs and RF4 PCBs will only increase. By leveraging the expertise of a trusted high Tg PCB manufacturer, you can stay ahead of the curve and develop innovative solutions that push the boundaries of electronic design and functionality.

No responses yet