Introduction

We are thrilled to announce a significant PCB Price Reduction across our entire product line. As a leading provider of high-quality printed circuit boards, we understand the importance of offering competitive prices without compromising on quality. This article will explore the details of our PCB price reduction, the factors that have made it possible, and how our customers can benefit from these changes.

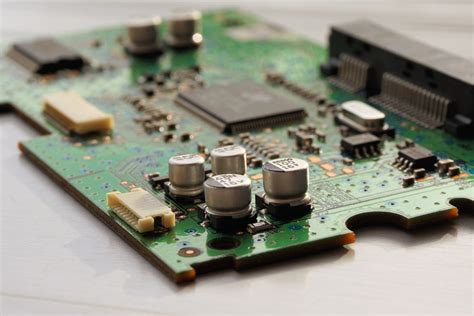

What is a PCB?

A printed circuit board (PCB) is a fundamental component in nearly all electronic devices. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, connect various electronic components, such as resistors, capacitors, and integrated circuits, to create a functional electronic circuit.

PCBs come in various types, depending on their complexity and application:

| PCB Type | Description |

|---|---|

| Single-sided | Conductive traces on one side of the board |

| Double-sided | Conductive traces on both sides of the board |

| Multi-layer | Multiple layers of conductive traces separated by insulating layers |

| Flexible | Made of flexible materials for use in applications requiring bending or folding |

| Rigid-Flex | Combination of rigid and flexible sections for complex designs |

The importance of PCBs in electronics manufacturing

PCBs play a crucial role in the electronics industry, as they provide a reliable and efficient means of interconnecting electronic components. Some of the key benefits of using PCBs include:

- Miniaturization: PCBs allow for the compact assembly of electronic components, enabling the creation of smaller, more portable devices.

- Reliability: Well-designed PCBs ensure stable connections between components, reducing the risk of failures caused by loose or faulty wiring.

- Mass production: PCBs are designed for automated assembly, which facilitates the mass production of electronic devices, reducing manufacturing costs and time to market.

- Consistency: Automated PCB Assembly ensures consistent quality across multiple units, minimizing the risk of human error.

Factors contributing to our PCB price reduction

Several factors have contributed to our ability to reduce PCB prices without compromising on quality:

Advancements in manufacturing technology

Continuous advancements in PCB manufacturing technology have enabled us to optimize our production processes, resulting in increased efficiency and reduced costs. Some of these advancements include:

- Automated optical inspection (AOI): AOI systems use high-resolution cameras and advanced algorithms to detect manufacturing defects, ensuring consistent quality and reducing manual inspection time.

- Surface mount technology (SMT): SMT allows for the automated placement of components onto the PCB surface, increasing assembly speed and accuracy while reducing labor costs.

- Inkjet printing: Inkjet printing technology enables the precise application of solder paste and other materials, minimizing waste and reducing costs.

Streamlined supply chain management

We have worked diligently to optimize our supply chain management, establishing strong relationships with our suppliers and implementing efficient inventory management systems. By streamlining our supply chain, we have been able to:

- Secure better pricing on raw materials through bulk purchasing and long-term contracts.

- Reduce inventory holding costs by implementing just-in-time (JIT) inventory management, ensuring that materials are available when needed without excessive stockpiling.

- Minimize transportation costs by strategically locating our manufacturing facilities and warehouses close to key suppliers and customers.

Economies of scale

As our customer base has grown, we have been able to leverage economies of scale to reduce our production costs. By increasing our production volume, we have been able to:

- Distribute fixed costs, such as equipment and facility expenses, across a larger number of units, reducing the cost per unit.

- Negotiate better prices with our suppliers due to increased purchasing power.

- Optimize our workforce utilization, ensuring that our employees are working efficiently and productively.

Benefits of our PCB price reduction for customers

Our PCB price reduction offers several significant benefits for our customers:

Cost savings

The most obvious benefit of our price reduction is the direct cost savings for our customers. By lowering the cost of our PCBs, we enable our customers to:

- Reduce their overall production costs, which can lead to increased profitability or more competitive pricing for their end products.

- Allocate the saved funds towards other aspects of their business, such as research and development, marketing, or customer support.

Increased competitiveness

With lower PCB costs, our customers can become more competitive in their respective markets. They can either pass the cost savings on to their customers by offering lower prices or reinvest the savings into product improvements or innovation, enhancing their market position.

Access to high-quality PCBs

Despite the price reduction, we remain committed to providing the highest quality PCBs. Our customers can continue to rely on us for well-designed, reliable PCBs that meet their specific requirements. We understand that the quality of our PCBs directly impacts the performance and reliability of our customers’ end products, and we will not compromise on this aspect.

Strengthened partnerships

Our PCB price reduction demonstrates our commitment to our customers’ success. By offering more competitive pricing, we aim to strengthen our partnerships with our customers, fostering long-term relationships built on trust, reliability, and mutual growth.

How to take advantage of our PCB price reduction

Taking advantage of our PCB price reduction is simple:

- Contact our sales team to discuss your specific PCB requirements and to request a quote based on our new pricing structure.

- Provide us with your PCB design files, specifying the desired quantities and lead times.

- Our team will review your requirements and provide you with a detailed quote, highlighting the cost savings compared to our previous pricing.

- Upon accepting the quote, your order will be processed, and your high-quality, cost-effective PCBs will be manufactured and delivered according to your specifications.

Frequently Asked Questions (FAQ)

1. Will the price reduction affect the quality of the PCBs?

No, the price reduction will not affect the quality of our PCBs. We remain committed to providing the highest quality products and will not compromise on this aspect. The price reduction has been made possible through advancements in manufacturing technology, streamlined supply chain management, and economies of scale.

2. Is the price reduction applicable to all PCB Types and quantities?

Yes, the price reduction applies to our entire PCB product line, including single-sided, double-sided, multi-layer, flexible, and rigid-Flex PCBs. The reduction is also applicable to all order quantities, although larger orders may qualify for additional discounts.

3. How long will the reduced prices be in effect?

The reduced prices are not a limited-time offer but rather a result of our ongoing efforts to optimize our processes and provide the best value to our customers. We intend to maintain these competitive prices for the foreseeable future, subject to market conditions and raw material costs.

4. Can I request a quote based on the new pricing for an existing PCB design?

Yes, you can request a new quote for an existing PCB design. Simply contact our sales team and provide them with your design files, specifying that you would like a quote based on our new pricing structure.

5. How will the price reduction impact lead times?

The price reduction will not have a negative impact on our lead times. In fact, our streamlined processes and efficient supply chain management may even lead to improved lead times in some cases. However, lead times may still vary depending on the complexity of your PCB design and the requested quantities.

Conclusion

Our PCB price reduction is a testament to our commitment to providing high-quality, cost-effective solutions to our customers. By leveraging advancements in manufacturing technology, streamlining our supply chain management, and benefiting from economies of scale, we have been able to lower our prices without compromising on quality.

We believe that this price reduction will not only benefit our customers directly through cost savings but also indirectly by enabling them to become more competitive in their respective markets. As we continue to grow and evolve, we remain dedicated to supporting our customers’ success and building long-lasting partnerships based on trust, reliability, and mutual growth.

If you have any questions about our PCB price reduction or would like to request a quote for your PCB requirements, please do not hesitate to contact our sales team. We look forward to working with you and providing you with the high-quality, cost-effective PCBs you need to succeed in today’s competitive electronics industry.

No responses yet