Understanding PCB Types

PCBs come in different forms, each designed to meet specific requirements and applications. The main types of PCBs include:

- Single-sided PCBs

- Double-sided PCBs

- Multi-layer PCBs

- Flexible PCBs

- Rigid-Flex PCBs

Let’s take a closer look at each type and their characteristics.

Single-Sided PCBs

Single-sided PCBs, also known as single-layer PCBs, have conductive traces and components on only one side of the board. The other side is typically used for component labeling and does not contain any conductive paths. Single-sided PCBs are the simplest and most cost-effective type of PCB, making them suitable for basic electronic projects and low-density designs.

Advantages of single-sided PCBs:

– Low production cost

– Quick and easy to manufacture

– Ideal for simple circuits and low-density designs

Disadvantages of single-sided PCBs:

– Limited routing options due to single-sided design

– Not suitable for complex or high-density circuits

– Prone to electromagnetic interference (EMI) and signal integrity issues

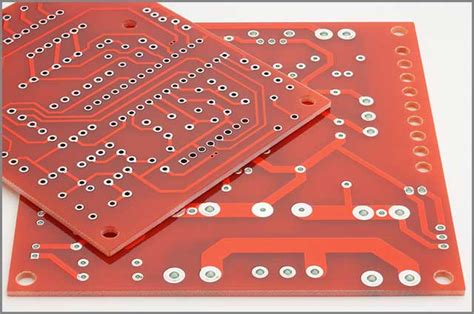

Double-Sided PCBs

Double-sided PCBs have conductive traces and components on both sides of the board, allowing for more complex routing and higher component density compared to single-sided PCBs. The two layers are connected through vias, which are small holes drilled through the board and plated with conductive material. Double-sided PCBs offer improved performance and are commonly used in a wide range of electronic devices.

Advantages of double-sided PCBs:

– Increased routing options and component density

– Better signal integrity and reduced EMI

– Suitable for more complex designs and applications

Disadvantages of double-sided PCBs:

– Higher production cost compared to single-sided PCBs

– More complex manufacturing process

– Potential for crosstalk between layers

Multi-Layer PCBs

Multi-layer PCBs consist of three or more conductive layers, separated by insulating material. These layers are interconnected through vias, allowing for even more complex routing and higher component density than double-sided PCBs. Multi-layer PCBs are commonly used in advanced electronic systems, such as smartphones, computers, and aerospace applications, where high performance and compact design are essential.

Advantages of multi-layer PCBs:

– High component density and complex routing capabilities

– Excellent signal integrity and reduced EMI

– Suitable for advanced and high-speed applications

Disadvantages of multi-layer PCBs:

– Higher production cost compared to single-sided and double-sided PCBs

– Complex manufacturing process

– Potential for signal integrity issues if not designed properly

Flexible PCBs

Flexible PCBs, also known as flex circuits, are made from thin, flexible materials such as polyimide or polyester. These PCBs can bend and conform to various shapes, making them ideal for applications where flexibility and space constraints are crucial. Flexible PCBs are commonly used in wearable devices, medical equipment, and aerospace systems.

Advantages of flexible PCBs:

– Flexibility and ability to conform to different shapes

– Lightweight and compact design

– Resistance to vibration and shock

Disadvantages of flexible PCBs:

– Higher production cost compared to rigid PCBs

– Limited component mounting options

– Potential for reduced durability in high-stress applications

Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs, consisting of rigid sections connected by flexible sections. This hybrid design allows for the integration of multiple circuit boards into a single, compact package. Rigid-flex PCBs are commonly used in applications that require high reliability, such as aerospace, military, and medical devices.

Advantages of rigid-flex PCBs:

– Combines the benefits of rigid and flexible PCBs

– Improved reliability and durability

– Compact design and reduced assembly time

Disadvantages of rigid-flex PCBs:

– High production cost due to complex manufacturing process

– Requires specialized design and fabrication expertise

– Limited availability of suppliers and longer lead times

The Most Common Type of PCB: Double-Sided PCBs

Among the various types of PCBs, double-sided PCBs are the most common type used in the electronics industry. This popularity can be attributed to several factors:

-

Versatility: Double-sided PCBs offer a balance between complexity and cost, making them suitable for a wide range of applications, from consumer electronics to industrial systems.

-

Increased routing options: With conductive traces on both sides of the board, double-sided PCBs provide more routing options and higher component density compared to single-sided PCBs, allowing for more complex designs.

-

Improved performance: Double-sided PCBs offer better signal integrity and reduced electromagnetic interference (EMI) compared to single-sided PCBs, resulting in improved overall performance.

-

Cost-effectiveness: While double-sided PCBs are more expensive than single-sided PCBs, they are still more cost-effective than multi-layer PCBs for many applications. This balance between cost and performance makes them an attractive choice for a wide range of products.

-

Manufacturing accessibility: Double-sided PCBs are easier to manufacture than multi-layer PCBs, with a less complex fabrication process and wider availability of suppliers. This accessibility contributes to their widespread adoption in the electronics industry.

Applications of Double-Sided PCBs

Double-sided PCBs find applications in various industries and products, including:

- Consumer electronics: Smartphones, tablets, laptops, and home appliances

- Industrial automation: Control systems, sensors, and data acquisition devices

- Automotive electronics: Engine control units, infotainment systems, and safety devices

- Medical devices: Diagnostic equipment, monitoring systems, and implantable devices

- Telecommunications: Routers, switches, and network equipment

The table below provides a summary of the applications and benefits of double-sided PCBs:

| Industry | Applications | Benefits |

|---|---|---|

| Consumer Electronics | Smartphones, tablets, laptops, home appliances | Compact design, improved performance, cost-effective |

| Industrial Automation | Control systems, sensors, data acquisition devices | Reliable performance, EMI reduction, suitable for complex designs |

| Automotive Electronics | Engine control units, infotainment systems, safety devices | Robust design, high component density, improved signal integrity |

| Medical Devices | Diagnostic equipment, monitoring systems, implantable devices | Compact design, reliability, suitable for complex circuits |

| Telecommunications | Routers, switches, network equipment | High-speed performance, EMI reduction, cost-effective |

Frequently Asked Questions (FAQ)

- What is the difference between single-sided and double-sided PCBs?

-

Single-sided PCBs have conductive traces and components on only one side of the board, while double-sided PCBs have conductive traces and components on both sides, connected through vias.

-

Why are double-sided PCBs the most common type of PCB?

-

Double-sided PCBs are the most common type due to their versatility, increased routing options, improved performance, cost-effectiveness, and manufacturing accessibility compared to other types of PCBs.

-

What are the advantages of using double-sided PCBs?

-

Advantages of double-sided PCBs include increased routing options and component density, better signal integrity and reduced EMI, and suitability for more complex designs and applications.

-

In which industries are double-sided PCBs commonly used?

-

Double-sided PCBs are commonly used in various industries, including consumer electronics, industrial automation, automotive electronics, medical devices, and telecommunications.

-

Are double-sided PCBs more expensive than single-sided PCBs?

- Yes, double-sided PCBs are more expensive than single-sided PCBs due to their more complex manufacturing process and increased capabilities. However, they are still more cost-effective than multi-layer PCBs for many applications.

Conclusion

In conclusion, double-sided PCBs are the most common type of PCB used in the electronics industry due to their versatility, improved performance, cost-effectiveness, and manufacturing accessibility. They offer a balance between complexity and cost, making them suitable for a wide range of applications across various industries, from consumer electronics to medical devices.

As technology continues to advance and the demand for more complex and compact electronic devices grows, the importance of double-sided PCBs is likely to remain significant. However, it is essential to consider the specific requirements of each application and evaluate other types of PCBs, such as multi-layer or flexible PCBs, when necessary.

By understanding the characteristics, advantages, and applications of different PCB types, engineers and designers can make informed decisions when developing electronic products, ensuring optimal performance, reliability, and cost-effectiveness.

No responses yet