What is a Breadboard?

A breadboard is a solderless prototyping board used for building and testing electronic circuits. It consists of a plastic board with numerous holes arranged in a grid pattern. These holes are connected internally in a specific manner, allowing electronic components to be inserted and connected without the need for soldering.

How does a Breadboard work?

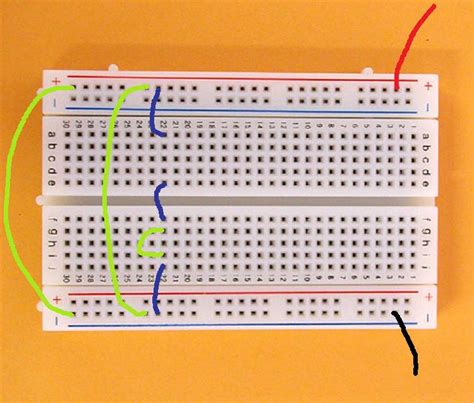

Breadboards have metal clips beneath each hole that grip the leads of electronic components and wires, creating electrical connections. The holes are typically arranged in two main sections:

-

Terminal strips: These are the long horizontal rows at the top and bottom of the breadboard, often labeled with positive (+) and negative (-) signs. They are used for connecting power supply and ground connections.

-

Component matrix: This is the main area of the breadboard where components are inserted. The holes in this section are connected vertically in columns, allowing components to be connected in a specific pattern.

Advantages of using a Breadboard

-

Quick prototyping: Breadboards allow for rapid prototyping and experimentation with circuit designs. Components can be easily inserted, removed, and rearranged without the need for soldering.

-

Reusability: Components can be reused multiple times on a breadboard, making it cost-effective for testing and iterating on designs.

-

Easy modification: Circuit designs can be easily modified on a breadboard by simply moving components or wires to different locations.

Disadvantages of using a Breadboard

-

Limited durability: Breadboards are not designed for permanent installations or rough handling. The connections can become loose over time, and the board itself is prone to wear and tear.

-

Size limitations: Breadboards have a limited number of holes and connections, which can restrict the complexity and size of the circuits that can be built.

-

Lack of customization: Breadboards have a fixed layout and spacing between holes, which may not be optimal for certain circuit designs or components.

What is a PCB?

A printed circuit board (PCB) is a custom-designed board that has conductive tracks, pads, and other features etched onto a non-conductive substrate. PCBs are used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces.

How are PCBs manufactured?

The PCB manufacturing process typically involves the following steps:

-

Design: The circuit schematic is created using electronic design automation (EDA) software, which generates the necessary files for PCB fabrication.

-

Printing: The PCB design is printed onto a copper-clad substrate using a photoresist process or silk-screen printing.

-

Etching: The unwanted copper is removed using a chemical etching process, leaving only the desired conductive tracks.

-

Drilling: Holes are drilled into the PCB to allow for component mounting and electrical connections between layers (if applicable).

-

Finishing: The PCB undergoes various finishing processes, such as applying solder mask, silkscreen, and surface finishes.

Advantages of using a PCB

-

Durability: PCBs are designed for long-term use and can withstand harsh environments, vibrations, and temperature fluctuations.

-

Compact size: PCBs allow for miniaturization of electronic devices by integrating components and connections in a compact, organized manner.

-

Reproducibility: Once a PCB design is finalized, it can be easily reproduced in large quantities with consistent quality and performance.

-

Customization: PCBs can be customized to meet specific design requirements, including unique shapes, sizes, and component layouts.

Disadvantages of using a PCB

-

Higher cost: Designing and manufacturing PCBs can be more expensive compared to using breadboards, especially for low-volume productions or prototypes.

-

Longer development time: The PCB design and fabrication process can take longer than prototyping on a breadboard, as it requires careful planning, design, and manufacturing steps.

-

Limited flexibility: Once a PCB is manufactured, making changes or modifications to the circuit can be difficult and may require a new PCB design and fabrication.

Breadboard vs PCB: A Comparison

To better understand the differences between breadboards and PCBs, let’s compare them based on various factors:

| Factor | Breadboard | PCB |

|---|---|---|

| Prototyping | Quick and easy | Requires design and fabrication |

| Durability | Limited, prone to wear | High, designed for long-term use |

| Customization | Fixed layout and spacing | Highly customizable |

| Component Density | Low to moderate | High |

| Reproducibility | Not suitable for reproduction | Easily reproducible |

| Cost | Low, reusable components | Higher, especially for low-volume |

| Soldering | Not required | Required for component mounting |

When to use a Breadboard or a PCB

The choice between using a breadboard or a PCB depends on the specific requirements and stage of the electronic project.

When to use a Breadboard

-

Prototyping and experimentation: Breadboards are ideal for quickly testing and iterating on circuit designs, allowing for easy modifications and component replacements.

-

Educational purposes: Breadboards are often used in educational settings to teach electronic concepts and circuit building skills.

-

Low-complexity projects: For simple circuits with a limited number of components, a breadboard can be sufficient for the entire project.

When to use a PCB

-

Final product design: Once a circuit design has been tested and finalized, a PCB is the preferred choice for the end product, ensuring durability, reliability, and reproducibility.

-

High-complexity projects: For circuits with a large number of components, intricate connections, or high-frequency signals, a well-designed PCB is essential for optimal performance and signal integrity.

-

Mass production: If the electronic device will be produced in large quantities, using PCBs is more cost-effective and ensures consistent quality across all units.

FAQ

- Can I use a breadboard for a permanent installation?

-

While it is possible to use a breadboard for a permanent installation, it is not recommended. Breadboards are designed for prototyping and temporary use, and the connections can become loose over time, leading to reliability issues. For permanent installations, it is better to use a PCB.

-

Are there any limitations on the components I can use with a breadboard?

-

Breadboards are suitable for most through-hole components and some smaller surface-mount devices (SMDs). However, there are limitations on the size and pitch of the components that can be used. Components with very small leads or fine pitch may not be compatible with the standard spacing of breadboard holes.

-

Can I convert a breadboard circuit to a PCB?

-

Yes, it is possible to convert a breadboard circuit to a PCB design. Once the circuit has been tested and finalized on the breadboard, you can create a schematic and PCB layout using EDA software. This process involves translating the breadboard connections into a PCB design, considering factors such as component placement, routing, and design rules.

-

Are there any alternatives to breadboards for prototyping?

-

In addition to breadboards, there are other prototyping options available, such as prototype PCBs, stripboards, and perfboards. These alternatives offer different levels of flexibility and permanence compared to breadboards. Prototype PCBs are custom-designed boards that can be fabricated quickly, while stripboards and perfboards provide a more structured layout for soldering components.

-

Can I reuse components from a breadboard in a PCB?

- Yes, most components used on a breadboard can be reused in a PCB design. However, it is essential to consider the component specifications, such as package type and pitch, to ensure compatibility with the PCB layout. Some components may require adapters or special handling when transitioning from a breadboard to a PCB.

Conclusion

In conclusion, while breadboards and PCBs serve the purpose of connecting electronic components, they have distinct differences in terms of prototyping, durability, customization, and application. Breadboards are ideal for quick prototyping, experimentation, and educational purposes, while PCBs are better suited for final product designs, high-complexity projects, and mass production.

The choice between using a breadboard or a PCB depends on the specific requirements and stage of the electronic project. Understanding the advantages and disadvantages of each option can help you make an informed decision based on your project’s needs.

Ultimately, breadboards and PCBs are complementary tools in the world of electronics prototyping and design. Breadboards provide a quick and flexible way to test and iterate on circuit ideas, while PCBs offer the durability, reliability, and reproducibility necessary for final products and large-scale manufacturing.

No responses yet