Introduction to RAYPCB Stackup

RAYPCB, a leading manufacturer of high-quality printed Circuit Boards (PCBs), has recently updated its standard stackup for multi-layer PCBs. This update aims to improve the performance, reliability, and manufacturability of PCBs, catering to the ever-evolving needs of the electronics industry. In this article, we will explore the significance of PCB stackups, the details of RAYPCB’s updated standard stackup, and its benefits for customers.

Understanding PCB Stackups

What is a PCB Stackup?

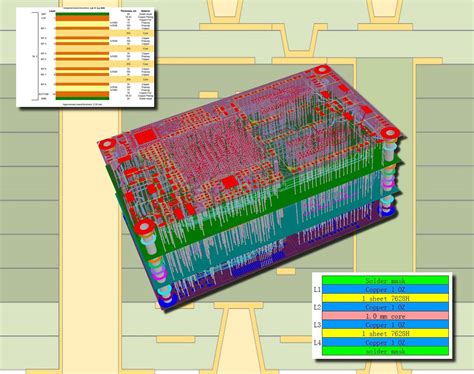

A PCB stackup refers to the arrangement of copper layers, insulating materials, and other components that make up a multi-layer PCB. It defines the number of layers, their order, and the materials used between each layer. The stackup plays a crucial role in determining the electrical, thermal, and mechanical properties of the PCB.

Importance of PCB Stackups

The proper design and implementation of a PCB stackup are essential for several reasons:

-

Signal Integrity: The stackup influences the signal integrity of the PCB by affecting factors such as impedance, crosstalk, and electromagnetic interference (EMI).

-

Power Distribution: The arrangement of power and ground planes in the stackup impacts the efficiency and stability of power distribution across the PCB.

-

Thermal Management: The choice of materials and their placement in the stackup affects the PCB’s ability to dissipate heat, which is crucial for the longevity and performance of the components.

-

Manufacturing Feasibility: The stackup design must consider the limitations and capabilities of the manufacturing process to ensure the PCB can be produced reliably and cost-effectively.

RAYPCB’s Updated Standard Stackup

Overview of the Update

RAYPCB has updated its standard stackup for multi-layer PCBs to address the growing demands of the industry. The updated stackup incorporates advanced materials, optimized layer arrangements, and improved manufacturing techniques to enhance the overall performance and reliability of the PCBs.

Key Features of the Updated Stackup

-

Expanded Layer Options: RAYPCB now offers a wider range of layer options, from 4 layers up to 24 layers, to accommodate various design requirements.

-

High-Performance Materials: The updated stackup utilizes high-performance materials, such as low-loss dielectrics and high-speed laminates, to minimize signal loss and improve signal integrity.

-

Optimized Power Distribution: The arrangement of power and ground planes has been optimized to ensure stable and efficient power distribution across the PCB.

-

Enhanced Thermal Management: The stackup incorporates thermally conductive materials and strategically placed thermal vias to improve heat dissipation and prevent thermal hotspots.

-

Improved Manufacturability: The updated stackup design takes into account the latest manufacturing technologies and best practices to ensure consistent quality and reliability.

Stackup Configuration Examples

Here are a few examples of RAYPCB’s updated standard stackup configurations:

| Layers | Stackup Configuration |

|---|---|

| 4 | Signal – Ground – Power – Signal |

| 6 | Signal – Ground – Signal – Power – Ground – Signal |

| 8 | Signal – Ground – Signal – Power – Ground – Signal – Power – Signal |

| 12 | Signal – Ground – Signal – Power – Ground – Signal – Power – Signal – Ground – Signal – Power – Signal |

Benefits of RAYPCB’s Updated Standard Stackup

Improved Signal Integrity

The use of high-performance materials and optimized layer arrangements in the updated stackup significantly improves signal integrity. This enhancement reduces signal loss, minimizes crosstalk, and mitigates EMI issues, resulting in better overall performance of the PCB.

Efficient Power Distribution

The strategic placement of power and ground planes in the updated stackup ensures efficient and stable power distribution across the PCB. This improvement helps minimize voltage drops, reduces power supply noise, and enhances the reliability of the PCB.

Enhanced Thermal Management

The incorporation of thermally conductive materials and thermal vias in the updated stackup facilitates better heat dissipation. This enhancement prevents thermal hotspots, improves the longevity of components, and enables the PCB to operate reliably even in demanding environments.

Increased Manufacturability

RAYPCB’s updated standard stackup takes into account the latest manufacturing technologies and best practices. This consideration ensures that the PCBs can be manufactured consistently and cost-effectively, reducing the risk of production delays and quality issues.

Flexibility in Design

With the expanded range of layer options and the availability of advanced materials, RAYPCB’s updated standard stackup offers greater flexibility in PCB Design. This flexibility allows customers to tailor their PCBs to specific requirements, whether it’s high-speed applications, dense component integration, or harsh environmental conditions.

Frequently Asked Questions (FAQ)

-

Q: What is the maximum number of layers supported in RAYPCB’s updated standard stackup?

A: RAYPCB’s updated standard stackup supports up to 24 layers, catering to a wide range of design complexities. -

Q: Can RAYPCB accommodate custom stackup requirements?

A: Yes, RAYPCB can work with customers to develop custom stackups that meet specific design requirements, in addition to the standard stackup options. -

Q: How does the updated stackup improve signal integrity?

A: The updated stackup utilizes high-performance materials and optimized layer arrangements to minimize signal loss, reduce crosstalk, and mitigate EMI issues, resulting in improved signal integrity. -

Q: What are the benefits of the enhanced thermal management in the updated stackup?

A: The enhanced thermal management in the updated stackup helps prevent thermal hotspots, improves the longevity of components, and ensures reliable operation of the PCB even in demanding environments. -

Q: How does the updated stackup impact the manufacturing process?

A: The updated stackup design takes into account the latest manufacturing technologies and best practices, ensuring consistent quality and reliability while reducing the risk of production delays and quality issues.

Conclusion

RAYPCB’s updated standard stackup for multi-layer PCBs represents a significant advancement in PCB design and manufacturing. By incorporating high-performance materials, optimized layer arrangements, and improved manufacturing techniques, the updated stackup enhances signal integrity, power distribution, thermal management, and manufacturability. These improvements translate to better performance, reliability, and flexibility for customers across various industries. With its commitment to innovation and customer satisfaction, RAYPCB continues to lead the way in providing high-quality PCB solutions to meet the evolving needs of the electronics industry.

No responses yet