What is Thermal Capacity?

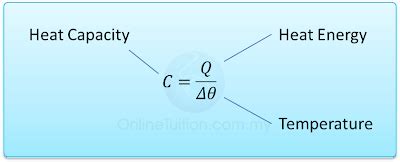

Thermal capacity, also known as heat capacity, is a physical property that represents the amount of heat required to raise the temperature of a substance by one degree Celsius (or Kelvin). It is expressed in units of joules per kelvin (J/K) or joules per degree Celsius (J/°C).

The thermal capacity of a material depends on its mass and specific heat capacity. The specific heat capacity is the amount of heat required to raise the temperature of one gram of a substance by one degree Celsius. It is expressed in units of joules per gram per degree Celsius (J/g·°C).

Thermal Properties of FR4

FR4 has several thermal properties that make it suitable for use in electronic applications:

-

Thermal Conductivity: FR4 has a relatively low thermal conductivity, ranging from 0.3 to 0.4 W/m·K. This means that it does not conduct heat well, which can be beneficial in some applications where thermal insulation is desired.

-

Glass Transition Temperature: The glass transition temperature (Tg) of FR4 is around 135°C. Above this temperature, the material begins to soften and lose its mechanical properties. It is essential to keep the operating temperature of FR4 below its Tg to maintain its structural integrity.

-

Coefficient of Thermal Expansion: FR4 has a coefficient of thermal expansion (CTE) of approximately 14 to 16 ppm/°C in the x-y plane and 50 to 70 ppm/°C in the z-axis. This means that the material expands and contracts with changes in temperature, which can lead to mechanical stress and warping if not properly managed.

Thermal Capacity of FR4

The specific heat capacity of FR4 is approximately 1.1 J/g·°C. This value can vary slightly depending on the specific composition and manufacturing process of the material.

To calculate the thermal capacity of an FR4 PCB, you need to know its mass. The thermal capacity is then calculated by multiplying the mass by the specific heat capacity:

Thermal Capacity (J/°C) = Mass (g) × Specific Heat Capacity (J/g·°C)

For example, if an FR4 PCB has a mass of 50 grams, its thermal capacity would be:

Thermal Capacity = 50 g × 1.1 J/g·°C = 55 J/°C

This means that it would require 55 joules of heat energy to raise the temperature of the PCB by one degree Celsius.

Importance of Thermal Management in PCB Design

Proper thermal management is crucial in PCB design to ensure the reliability and longevity of electronic components. When components generate heat during operation, it must be effectively dissipated to prevent overheating and potential failure.

Some strategies for thermal management in PCB design include:

-

Copper Pours: Adding copper pours to the PCB layout can help distribute heat more evenly across the board. Copper has a high thermal conductivity, which allows it to efficiently transfer heat away from hot spots.

-

Thermal Vias: Thermal vias are small holes drilled through the PCB that are filled with conductive material, such as copper. They provide a path for heat to transfer from one layer of the board to another, helping to dissipate heat more effectively.

-

Heat Sinks: Heat sinks are metal components that are attached to high-power components to help dissipate heat. They work by increasing the surface area available for heat transfer and allowing air to flow over the component, carrying heat away.

-

Airflow: Ensuring adequate airflow over the PCB can help remove heat from the system. This can be achieved through the use of fans, vents, or other cooling solutions.

FR4 vs. Other PCB Materials

While FR4 is the most common material used for PCBs, there are other materials available that may be more suitable for certain applications. Some alternative PCB materials include:

-

Aluminum: Aluminum PCBs have a higher thermal conductivity than FR4, making them better suited for applications that generate a lot of heat. However, they are more expensive and have a higher CTE, which can lead to mechanical stress.

-

Ceramic: Ceramic PCBs have excellent thermal properties and can withstand high temperatures. They are often used in high-power applications, such as automotive and aerospace electronics. However, they are brittle and more expensive than FR4.

-

Polyimide: Polyimide PCBs have a higher glass transition temperature than FR4, making them suitable for high-temperature applications. They also have a lower CTE, which reduces mechanical stress. However, they are more expensive and have a lower thermal conductivity than FR4.

Frequently Asked Questions (FAQ)

-

Q: What is the thermal conductivity of FR4?

A: The thermal conductivity of FR4 ranges from 0.3 to 0.4 W/m·K. -

Q: What is the glass transition temperature of FR4?

A: The glass transition temperature (Tg) of FR4 is around 135°C. -

Q: What is the specific heat capacity of FR4?

A: The specific heat capacity of FR4 is approximately 1.1 J/g·°C. -

Q: How can I calculate the thermal capacity of an FR4 PCB?

A: To calculate the thermal capacity of an FR4 PCB, multiply its mass (in grams) by the specific heat capacity (1.1 J/g·°C). -

Q: What are some strategies for thermal management in PCB design?

A: Some strategies for thermal management in PCB design include using copper pours, thermal vias, heat sinks, and ensuring adequate airflow over the board.

Conclusion

Understanding the thermal capacity of FR4 is essential for designing reliable and efficient electronic devices. With a specific heat capacity of approximately 1.1 J/g·°C, FR4 PCBs require careful thermal management to prevent overheating and component failure.

By incorporating techniques such as copper pours, thermal vias, heat sinks, and adequate airflow, designers can effectively dissipate heat and ensure the long-term performance of their electronic systems. While FR4 is the most common PCB material, other options like aluminum, ceramic, and polyimide may be more suitable for specific high-temperature or high-power applications.

As the electronics industry continues to evolve, with devices becoming smaller and more powerful, the importance of thermal management in PCB design will only continue to grow. By understanding the thermal properties of materials like FR4 and implementing effective thermal management strategies, designers can create robust and reliable electronic systems that stand the test of time.

| Property | Value |

|---|---|

| Thermal Conductivity | 0.3 to 0.4 W/m·K |

| Glass Transition Temperature (Tg) | 135°C |

| Specific Heat Capacity | 1.1 J/g·°C |

| CTE (x-y plane) | 14 to 16 ppm/°C |

| CTE (z-axis) | 50 to 70 ppm/°C |

Table 1: Thermal properties of FR4.

| Material | Thermal Conductivity (W/m·K) | Glass Transition Temperature (°C) | CTE (ppm/°C) |

|---|---|---|---|

| FR4 | 0.3 to 0.4 | 135 | 14 to 70 |

| Aluminum | 150 to 200 | N/A | 23 to 24 |

| Ceramic | 20 to 30 | >1000 | 6 to 8 |

| Polyimide | 0.1 to 0.2 | 260 to 400 | 12 to 16 |

Table 2: Comparison of thermal properties for different PCB materials.

No responses yet