What is FR4 Insulation?

FR4 is a composite material consisting of a flame-retardant epoxy resin reinforced with woven fiberglass cloth. The “FR” in FR4 stands for “Flame Retardant,” indicating its inherent ability to resist the spread of flames and self-extinguish when the heat source is removed. The number “4” represents the woven glass reinforcement used in the laminate.

Composition of FR4

The two main components of FR4 are:

- Epoxy Resin: A thermosetting polymer that provides excellent adhesion, chemical resistance, and insulating properties.

- Woven Fiberglass: A fabric made from fine glass fibers that offers mechanical strength, dimensional stability, and electrical insulation.

The combination of these materials results in a laminate with superior properties compared to other insulating materials.

Manufacturing Process of FR4

The manufacturing process of FR4 involves several steps to ensure a high-quality, consistent product:

-

Impregnation: The woven fiberglass cloth is impregnated with the epoxy resin under controlled conditions to ensure thorough saturation.

-

Layup: Multiple layers of the impregnated fiberglass are stacked together to achieve the desired thickness and properties.

-

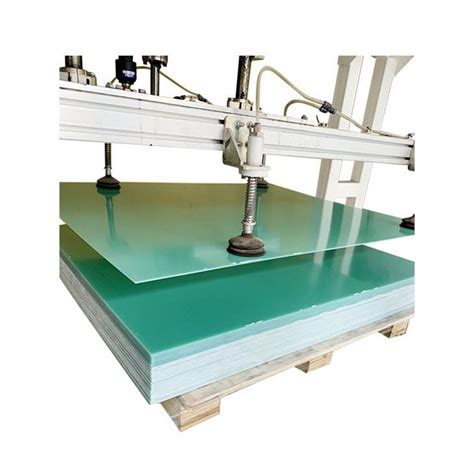

Pressing: The stacked layers are placed in a hot press, where heat and pressure are applied to cure the epoxy resin and bond the layers together.

-

Curing: The laminate undergoes a carefully controlled curing process to ensure complete cross-linking of the epoxy resin, resulting in a strong, stable material.

-

Cutting and Finishing: The cured FR4 laminate is cut to the desired size and shape, and the surface is finished according to the application requirements.

Properties of FR4 Insulation

FR4 insulation exhibits several key properties that make it an excellent choice for various applications:

Mechanical Properties

| Property | Value |

|---|---|

| Density | 1.85 g/cm³ |

| Tensile Strength | 310 MPa |

| Flexural Strength | 415 MPa |

| Compressive Strength | 415 MPa |

| Young’s Modulus | 24 GPa |

| Poisson’s Ratio | 0.136 |

| Shear Strength | 186 MPa |

FR4 offers high mechanical strength, rigidity, and dimensional stability, making it suitable for applications that require structural integrity.

Thermal Properties

| Property | Value |

|---|---|

| Glass Transition Temperature | 130-140°C |

| Thermal Conductivity | 0.3 W/m·K |

| Coefficient of Thermal Expansion | 12-16 ppm/°C |

| Decomposition Temperature | >300°C |

FR4 maintains its mechanical and electrical properties over a wide temperature range and has a relatively low coefficient of thermal expansion, ensuring stable performance in varying thermal conditions.

Electrical Properties

| Property | Value |

|---|---|

| Dielectric Constant (1 MHz) | 4.5 |

| Dissipation Factor (1 MHz) | 0.02 |

| Dielectric Strength | 20 kV/mm |

| Volume Resistivity | 10¹⁴ Ω·cm |

| Surface Resistivity | 10¹⁵ Ω |

FR4 provides excellent electrical insulation, with high dielectric strength and resistivity, making it ideal for electronic applications.

Applications of FR4 Insulation

FR4 insulation finds applications in various industries due to its versatile properties:

-

Electronics: FR4 is the most common substrate material for PCBs, used in consumer electronics, telecommunications, automotive electronics, and industrial control systems.

-

Aerospace: The high strength-to-weight ratio and thermal stability of FR4 make it suitable for aerospace applications, such as avionics and satellite components.

-

Medical Devices: FR4’s biocompatibility and resistance to sterilization methods make it a choice material for medical device housings and components.

-

Industrial Equipment: FR4 is used in the construction of various industrial equipment, such as motors, transformers, and switchgear, thanks to its insulating properties and mechanical strength.

-

Energy: FR4 finds applications in renewable energy systems, such as wind turbines and solar panels, where its electrical insulation and environmental resistance are crucial.

Advantages of FR4 Insulation

FR4 insulation offers several advantages over other insulating materials:

-

Excellent Mechanical Properties: FR4’s high strength, stiffness, and dimensional stability make it suitable for applications that require structural integrity.

-

Superior Electrical Insulation: With high dielectric strength and resistivity, FR4 provides reliable electrical insulation for electronic applications.

-

Wide Temperature Range: FR4 maintains its properties over a broad temperature range, ensuring stable performance in varying thermal conditions.

-

Flame Retardancy: The inherent flame-retardant properties of FR4 minimize the risk of fire hazards and ensure safety in electronic devices.

-

Cost-Effective: FR4 is a cost-effective solution for many applications due to its widespread availability and efficient manufacturing process.

Frequently Asked Questions (FAQ)

-

Q: Is FR4 a fire-resistant material?

A: Yes, FR4 is a flame-retardant material that resists the spread of flames and self-extinguishes when the heat source is removed. -

Q: Can FR4 be used in high-temperature applications?

A: FR4 maintains its properties up to its glass transition temperature (130-140°C). For higher temperature applications, specialized high-temperature laminates like polyimide or high-Tg FR4 can be used. -

Q: Is FR4 suitable for outdoor applications?

A: FR4 offers good resistance to moisture and environmental factors, making it suitable for many outdoor applications. However, for extreme conditions, additional protective coatings or enclosures may be necessary. -

Q: Can FR4 be machined or drilled?

A: Yes, FR4 can be machined, drilled, and cut using standard tools and techniques. However, proper precautions should be taken to minimize dust generation and ensure operator safety. -

Q: Are there any alternatives to FR4 for PCB fabrication?

A: While FR4 is the most common material for PCBs, alternatives like high-frequency laminates (Rogers, Teflon), metal-core PCBs, and flexible PCBs are used for specific applications with unique requirements.

Conclusion

FR4 insulation is a versatile, high-performance material that has become indispensable in the electronics industry and beyond. Its excellent mechanical, thermal, and electrical properties, combined with its flame retardancy and cost-effectiveness, make it an ideal choice for a wide range of applications. As technology continues to advance, FR4 remains a crucial component in the development of reliable, safe, and efficient electronic devices and systems.

No responses yet