Introduction to Ceramic PCBs

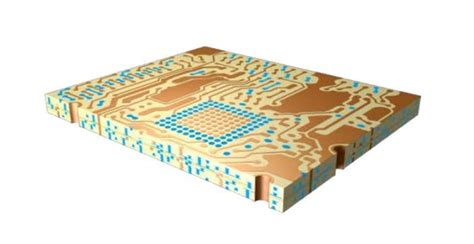

Ceramic printed circuit boards (PCBs) are a specialized type of PCB that use a ceramic substrate material instead of the more common FR-4 fiberglass. Ceramic PCBs offer several advantages over traditional PCBs, making them ideal for certain high-performance applications.

Ceramic PCBs are constructed by depositing conductive traces onto a ceramic substrate, typically alumina (aluminum oxide) or aluminum nitride. The ceramic material provides excellent electrical insulation, high Thermal conductivity, and superior mechanical strength compared to FR-4.

Advantages of Ceramic PCBs

- High thermal conductivity

- Excellent electrical insulation

- Low dielectric loss

- High mechanical strength

- Stable at high temperatures

- Resistant to chemicals and moisture

Applications of Ceramic PCBs

Ceramic PCBs are commonly used in demanding applications that require high reliability and performance, such as:

- Aerospace and defense electronics

- High-power LED lighting

- Automotive electronics

- Medical devices

- RF and microwave circuits

- High-temperature applications

Manufacturing Process of Ceramic PCBs

Substrate Preparation

The first step in manufacturing a ceramic PCB is preparing the ceramic substrate. Alumina (Al2O3) is the most commonly used ceramic material, although aluminum nitride (AlN) may be used for applications requiring even higher thermal conductivity.

The ceramic substrate is typically formed by pressing and sintering a powder mixture at high temperature (1600-1800°C). The resulting ceramic sheet is then ground and polished to achieve a smooth, flat surface.

Circuit Patterning

Next, the conductive circuit pattern is deposited onto the ceramic substrate. There are several methods for patterning the circuitry:

Thick Film

In the thick film process, a conductive paste (usually silver or gold) is screen printed onto the ceramic substrate. The paste is then fired at high temperature (850-1000°C) to form a conductive trace.

Thin Film

The thin film process involves depositing a thin layer of conductive material (usually copper) onto the ceramic substrate using sputtering or evaporation. The copper layer is then patterned using photolithography and etching.

Co-fired Ceramic

In the co-fired process, the conductive traces are screen printed onto individual layers of green (unfired) ceramic tape. The layers are then stacked, laminated, and fired together to form a monolithic structure.

Resistors and Capacitors

If required, resistors and capacitors can be integrated directly onto the ceramic substrate. Resistors are typically formed by screen printing a resistive paste and firing at high temperature. Capacitors can be formed by screen printing a dielectric layer between two conductive layers.

Singulation and Packaging

Finally, the individual ceramic PCBs are singulated (cut out) from the ceramic sheet using a dicing saw or laser. The PCBs are then packaged as needed for the specific application.

Properties of Ceramic PCBs

Thermal Conductivity

One of the key advantages of ceramic PCBs is their high thermal conductivity. Alumina has a thermal conductivity of 20-30 W/mK, while aluminum nitride can achieve 150-180 W/mK. This allows ceramic PCBs to efficiently dissipate heat, making them ideal for high-power applications.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Alumina (Al2O3) | 20-30 |

| Aluminum Nitride (AlN) | 150-180 |

| FR-4 | 0.3-0.4 |

Dielectric Properties

Ceramic materials also offer excellent dielectric properties, with low dielectric loss and high dielectric strength. This makes them well-suited for high-frequency RF and microwave applications.

| Material | Dielectric constant | Dielectric Loss Tangent |

|---|---|---|

| Alumina (Al2O3) | 9.8 | 0.0001 |

| Aluminum Nitride (AlN) | 8.8 | 0.0005 |

| FR-4 | 4.5 | 0.02 |

Mechanical Strength

Ceramic PCBs offer superior mechanical strength compared to traditional FR-4 PCBs. This makes them more resistant to vibration, shock, and physical stress.

| Material | Flexural Strength (MPa) |

|---|---|

| Alumina (Al2O3) | 400-500 |

| Aluminum Nitride (AlN) | 300-400 |

| FR-4 | 400-500 |

Thermal Stability

Ceramic PCBs are stable at high temperatures, making them suitable for applications that require operation in extreme thermal environments. Alumina and aluminum nitride can maintain their properties at temperatures up to 400°C and 600°C, respectively.

Design Considerations for Ceramic PCBs

Thermal Management

While ceramic PCBs offer excellent thermal conductivity, proper thermal management is still important to ensure reliable operation. Key considerations include:

- Proper heat sinking and cooling methods

- Thermal vias to conduct heat through the PCB

- Thermal interface materials to improve heat transfer

Mechanical Stress

Although ceramic PCBs are mechanically strong, they can be brittle and prone to cracking under excessive stress. Design considerations to mitigate mechanical stress include:

- Proper mounting and support

- Stress relief features (e.g., slots or holes)

- Minimizing large unsupported areas

Coefficient of Thermal Expansion (CTE)

Ceramic materials have a lower CTE than FR-4, which can lead to stress at the interface between the ceramic PCB and other components (e.g., metal heat sinks). Design considerations to address CTE mismatch include:

- Selecting components with similar CTEs

- Using compliant thermal interface materials

- Providing stress relief in the PCB Design

FAQ

Q1: What are the main advantages of ceramic PCBs over traditional FR-4 PCBs?

A1: Ceramic PCBs offer several key advantages, including high thermal conductivity, excellent electrical insulation, low dielectric loss, high mechanical strength, stability at high temperatures, and resistance to chemicals and moisture.

Q2: What are the most common ceramic materials used for PCBs?

A2: The most common ceramic materials used for PCBs are alumina (Al2O3) and aluminum nitride (AlN). Alumina is widely used due to its good balance of properties and lower cost, while aluminum nitride is used for applications requiring the highest thermal conductivity.

Q3: What manufacturing processes are used to produce ceramic PCBs?

A3: The main manufacturing processes for ceramic PCBs are thick film, thin film, and co-fired ceramic. Thick film involves screen printing a conductive paste, thin film uses sputtering or evaporation to deposit a conductive layer, and co-fired ceramic involves stacking and firing layers of ceramic tape with printed conductors.

Q4: What are some common applications for ceramic PCBs?

A4: Ceramic PCBs are commonly used in demanding applications that require high reliability and performance, such as aerospace and defense electronics, high-power LED lighting, automotive electronics, medical devices, RF and microwave circuits, and high-temperature applications.

Q5: What are some key design considerations when using ceramic PCBs?

A5: Some key design considerations for ceramic PCBs include thermal management to ensure proper heat dissipation, mechanical stress relief to prevent cracking, and accounting for the coefficient of thermal expansion (CTE) mismatch between the ceramic and other components. Proper component selection and PCB Layout techniques can help address these issues.

Conclusion

Ceramic PCBs offer a high-performance alternative to traditional FR-4 PCBs for demanding applications that require high thermal conductivity, excellent electrical insulation, and superior mechanical strength. By understanding the properties, manufacturing processes, and design considerations for ceramic PCBs, engineers can effectively utilize this technology to meet the needs of their specific applications.

No responses yet