Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, lighter, and more efficient electronic devices. As a result, the demand for SMT manufacturing services has increased significantly in recent years. However, finding a reliable and competent SMT manufacturer can be a daunting task, especially for those who are new to the industry. In this article, we will discuss six proven working tips to help you find good SMT manufacturers.

Tip 1: Define Your Requirements

Understanding Your Product

Before you start your search for an SMT manufacturer, it is essential to have a clear understanding of your product requirements. This includes the type of components you need, the size of your PCB, the required manufacturing capabilities, and any special requirements such as lead-free or RoHS compliance. Having a well-defined set of requirements will help you narrow down your search and find manufacturers that are best suited to your needs.

Determining Your Budget

Another crucial factor to consider is your budget. SMT manufacturing costs can vary significantly depending on the complexity of your design, the volume of your order, and the location of the manufacturer. It is important to have a realistic budget in mind and communicate it clearly with potential manufacturers to avoid any misunderstandings or surprises down the line.

Tip 2: Research Potential Manufacturers

Online Directories

One of the easiest ways to find potential SMT manufacturers is through online directories such as ThomasNet, GlobalSpec, and IPC. These directories allow you to search for manufacturers based on various criteria such as location, capabilities, certifications, and more. You can also read reviews and ratings from other customers to get an idea of their reputation and quality of service.

Industry Associations

Another great resource for finding SMT manufacturers is industry associations such as IPC (Association Connecting Electronics Industries) and SMTA (Surface Mount Technology Association). These associations have a vast network of member companies that offer various SMT manufacturing services. They also provide valuable resources such as training, standards, and best practices that can help you make informed decisions.

Tip 3: Evaluate Their Capabilities

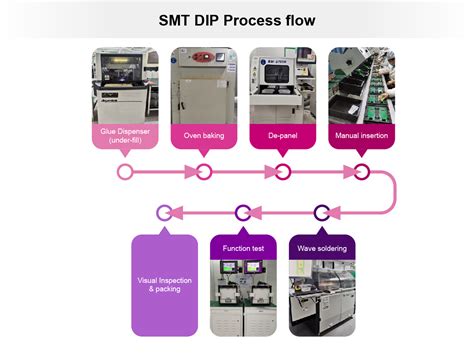

Manufacturing Equipment

Once you have a list of potential manufacturers, it is important to evaluate their manufacturing capabilities to ensure they can meet your requirements. One of the key factors to consider is their manufacturing equipment. Modern SMT manufacturing requires advanced equipment such as pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. Make sure the manufacturer has the necessary equipment and expertise to handle your specific needs.

Quality Control Processes

Another important factor to consider is the manufacturer’s quality control processes. SMT manufacturing involves many complex processes and variables that can affect the quality and reliability of the final product. A good manufacturer should have robust quality control processes in place, such as incoming inspection, in-process inspection, and final inspection. They should also have a documented quality management system (QMS) that meets industry standards such as ISO 9001 or AS9100.

Certifications and Standards

In addition to quality control processes, it is also important to consider the manufacturer’s certifications and compliance with industry standards. Some common certifications to look for include ISO 9001 (quality management), ISO 14001 (environmental management), and IATF 16949 (automotive quality management). Compliance with industry standards such as IPC-A-610 (acceptability of electronic assemblies) and J-STD-001 (requirements for soldered electrical and electronic assemblies) is also crucial.

Tip 4: Consider Location and Logistics

Proximity to Your Location

The location of the SMT manufacturer can have a significant impact on your supply chain efficiency and costs. If possible, it is preferable to choose a manufacturer that is located close to your facility or distribution center. This can help reduce shipping costs, lead times, and potential delays due to customs or transportation issues. However, if you are looking for lower costs or specific capabilities, you may need to consider manufacturers in other regions or countries.

Shipping and Logistics

In addition to proximity, it is also important to consider the manufacturer’s shipping and logistics capabilities. Do they have experience with international shipping and customs regulations? Can they provide flexible shipping options such as air, sea, or ground? Do they have a reliable network of carriers and partners to ensure timely delivery? These are all important questions to ask when evaluating potential manufacturers.

Communication and Language

Effective communication is critical in any manufacturing partnership, especially when dealing with complex technical requirements and tight deadlines. If you are considering an overseas manufacturer, it is important to ensure that they have adequate English language proficiency and communication channels such as email, phone, or video conferencing. Cultural differences and time zone differences can also pose challenges, so it is important to establish clear expectations and protocols upfront.

Tip 5: Request Quotes and Samples

Request for Quote (RFQ)

Once you have narrowed down your list of potential manufacturers based on their capabilities, location, and reputation, the next step is to request quotes for your specific project. A request for quote (RFQ) is a formal document that outlines your product requirements, quantities, and timeline. It allows the manufacturer to provide an accurate quote based on your specific needs and helps you compare costs and lead times across multiple suppliers.

Prototype and Samples

Before committing to a large-scale production run, it is always a good idea to request prototypes or samples from the manufacturer. This allows you to test the quality and functionality of the product and ensure that it meets your specifications. It also gives you an opportunity to provide feedback and make any necessary changes before going into full production. Most manufacturers offer prototyping services and can provide samples within a reasonable timeframe.

Tip 6: Verify References and Reputation

Customer References

One of the best ways to gauge the quality and reliability of an SMT manufacturer is to speak with their existing customers. Most manufacturers should be willing to provide references upon request, especially if they have a good track record. Reach out to these references and ask about their experience with the manufacturer, including quality, delivery, communication, and overall satisfaction. If possible, try to find references that have similar products or requirements to yours.

Online Reviews and Ratings

In addition to customer references, you can also research the manufacturer’s online reputation through reviews and ratings on various platforms such as Google, Yelp, or industry-specific forums. While not always reliable, these reviews can give you a general idea of the manufacturer’s strengths and weaknesses. Look for patterns or common themes in the reviews, such as consistent quality issues or exceptional customer service.

Financial Stability

Finally, it is important to consider the financial stability of the manufacturer, especially if you are planning a long-term partnership. You can request financial statements or credit reports to assess their financial health and ability to invest in new equipment or technologies. You can also check for any legal or regulatory issues that may affect their operations or reputation.

Conclusion

Finding a good SMT manufacturer requires careful research, evaluation, and due diligence. By following these six proven working tips, you can increase your chances of finding a reliable and competent partner that can help you bring your products to market quickly and efficiently. Remember to define your requirements clearly, research potential manufacturers thoroughly, evaluate their capabilities and certifications, consider location and logistics, request quotes and samples, and verify their references and reputation. With the right SMT manufacturer by your side, you can focus on your core business and leave the manufacturing to the experts.

FAQ

1. What is SMT manufacturing?

SMT (Surface Mount Technology) manufacturing is a process where electronic components are mounted directly onto the surface of a printed circuit board (PCB) using automated equipment such as pick-and-place machines and reflow ovens. This allows for smaller, lighter, and more efficient electronic devices compared to traditional through-hole manufacturing.

2. What are some common certifications to look for in an SMT manufacturer?

Some common certifications to look for in an SMT manufacturer include ISO 9001 (quality management), ISO 14001 (environmental management), and IATF 16949 (automotive quality management). Compliance with industry standards such as IPC-A-610 (acceptability of electronic assemblies) and J-STD-001 (requirements for soldered electrical and electronic assemblies) is also important.

3. How important is location when choosing an SMT manufacturer?

Location can have a significant impact on your supply chain efficiency and costs. Choosing a manufacturer that is located close to your facility or distribution center can help reduce shipping costs, lead times, and potential delays due to customs or transportation issues. However, if you are looking for lower costs or specific capabilities, you may need to consider manufacturers in other regions or countries.

4. What should I include in a request for quote (RFQ) for SMT manufacturing?

A request for quote (RFQ) for SMT manufacturing should include your product requirements, quantities, and timeline. This includes details such as the type of components, size of the PCB, required manufacturing capabilities, and any special requirements such as lead-free or RoHS compliance. The more specific and detailed your RFQ is, the more accurate the quote will be.

5. How can I verify the quality and reliability of an SMT manufacturer?

There are several ways to verify the quality and reliability of an SMT manufacturer, including:

– Requesting customer references and speaking with their existing customers about their experience

– Researching online reviews and ratings on various platforms such as Google, Yelp, or industry-specific forums

– Evaluating their manufacturing capabilities, quality control processes, and certifications

– Requesting prototypes or samples to test the quality and functionality of the product

– Assessing their financial stability through financial statements or credit reports

| Tip | Description |

|---|---|

| Define Your Requirements | Have a clear understanding of your product requirements, including components, PCB size, manufacturing capabilities, special requirements, and budget. |

| Research Potential Manufacturers | Use online directories, industry associations, and other resources to find potential SMT manufacturers that meet your criteria. |

| Evaluate Their Capabilities | Assess the manufacturer’s equipment, quality control processes, certifications, and compliance with industry standards. |

| Consider Location and Logistics | Choose a manufacturer that is located close to your facility or distribution center, if possible, and evaluate their shipping and logistics capabilities. |

| Request Quotes and Samples | Request formal quotes based on your specific requirements and ask for prototypes or samples to test the quality and functionality of the product. |

| Verify References and Reputation | Speak with the manufacturer’s existing customers, research online reviews and ratings, and assess their financial stability to gauge their quality and reliability. |

No responses yet