Introduction to LED PCB

An LED PCB, or Light Emitting Diode Printed Circuit Board, is a specialized type of circuit board designed to power and control LEDs. These boards are essential components in a wide range of electronic devices, from simple LED indicators to complex LED lighting systems and displays. LED PCBs are known for their efficiency, reliability, and versatility, making them a popular choice for various applications.

What is an LED?

Before diving into the details of LED PCBs, it’s important to understand what LEDs are. LEDs are semiconductor devices that emit light when an electric current passes through them. They are known for their energy efficiency, long lifespan, and ability to produce a wide range of colors. LEDs have revolutionized the lighting industry and are now used in numerous applications, including:

- General lighting

- Automotive lighting

- Backlighting for displays

- Signage and advertising

- Medical equipment

- And more

What is a PCB?

A Printed Circuit Board (PCB) is a thin board made of insulating material, such as fiberglass or composite epoxy, with conductive copper traces printed on its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electrical circuit. PCBs are used in virtually all electronic devices, as they provide a compact, reliable, and cost-effective way to assemble and connect electronic components.

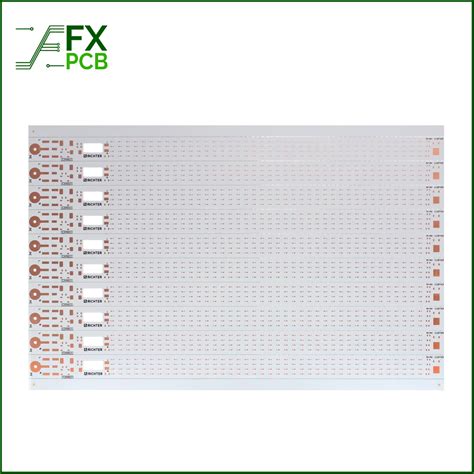

Types of LED PCBs

There are several types of LED PCBs, each designed for specific applications and requirements. Some of the most common types include:

Single-Sided LED PCBs

Single-sided LED PCBs have conductive traces and components on only one side of the board. They are the simplest and most cost-effective type of LED PCB, making them suitable for basic applications and low-power LED circuits.

Double-Sided LED PCBs

Double-sided LED PCBs have conductive traces and components on both sides of the board, connected through plated-through holes (PTHs). These boards offer higher component density and more complex circuit designs compared to single-sided PCBs. Double-sided LED PCBs are commonly used in applications that require more advanced LED control and functionality.

Multi-Layer LED PCBs

Multi-layer LED PCBs consist of three or more layers of conductive traces, separated by insulating layers. These boards offer the highest component density and the most complex circuit designs, making them suitable for advanced LED applications, such as high-power LED lighting systems and large LED displays.

Flexible LED PCBs

Flexible LED PCBs are made of thin, flexible insulating material, such as polyimide or polyester, with conductive traces printed on the surface. These boards can bend and conform to various shapes, making them ideal for applications where traditional rigid PCBs are not suitable, such as wearable electronics and automotive lighting.

Advantages of LED PCBs

LED PCBs offer several advantages over traditional lighting solutions and other types of circuit boards. Some of the key benefits include:

Energy Efficiency

LEDs are known for their high energy efficiency, consuming significantly less power than traditional lighting sources, such as incandescent bulbs and fluorescent tubes. By using LED PCBs, electronic devices can operate more efficiently, reducing energy consumption and costs.

Long Lifespan

LEDs have a much longer lifespan compared to traditional lighting sources, often lasting tens of thousands of hours. This longevity is extended to LED PCBs, which can operate reliably for extended periods without requiring frequent replacement or maintenance.

Compact Size

LED PCBs are typically smaller and more compact than other types of circuit boards, as LEDs themselves are small and require fewer additional components. This compact size allows for more efficient use of space in electronic devices and enables the development of smaller, more portable products.

Design Flexibility

LED PCBs can be designed to accommodate a wide range of LED configurations, colors, and power requirements. This flexibility allows for the creation of custom LED solutions tailored to specific applications and design needs.

Environmental Friendliness

LEDs do not contain hazardous materials, such as mercury, which are commonly found in traditional lighting sources. By using LED PCBs, electronic devices can be more environmentally friendly and easier to dispose of at the end of their life cycle.

LED PCB Design Considerations

When designing an LED PCB, several key factors must be considered to ensure optimal performance, reliability, and efficiency. These factors include:

LED Selection

Choosing the right LEDs for a specific application is crucial. Factors to consider include LED type (e.g., SMD, Through-hole), color, brightness, viewing angle, and power requirements. The selected LEDs should be compatible with the PCB design and meet the desired performance criteria.

Current and Voltage Requirements

LEDs require specific current and voltage levels to operate properly. The LED PCB design must include appropriate current-limiting resistors and voltage regulators to ensure that the LEDs receive the correct amount of power. Overdriving or underdriving LEDs can lead to reduced performance, shortened lifespan, or even failure.

Thermal Management

LEDs generate heat during operation, which can negatively impact their performance and lifespan if not properly managed. LED PCBs should incorporate thermal management techniques, such as the use of heat sinks, thermal vias, and appropriate PCB materials, to dissipate heat effectively and maintain optimal LED performance.

Layout and Routing

The layout and routing of an LED PCB play a critical role in its performance and reliability. The PCB design should minimize trace lengths, reduce electromagnetic interference (EMI), and ensure proper grounding. Additionally, the layout should consider factors such as component placement, signal integrity, and manufacturability.

Manufacturability

LED PCBs should be designed with manufacturability in mind to ensure cost-effective and reliable production. This includes considering factors such as component placement, Solder mask design, and the use of standard PCB fabrication processes and materials.

LED PCB Applications

LED PCBs are used in a wide range of applications across various industries. Some of the most common applications include:

General Lighting

LED PCBs are widely used in general lighting applications, such as indoor and outdoor lighting, task lighting, and decorative lighting. They offer energy-efficient, long-lasting, and customizable lighting solutions for residential, commercial, and industrial settings.

Automotive Lighting

LED PCBs are increasingly used in automotive lighting applications, including headlights, taillights, interior lighting, and instrument panel backlighting. They offer improved visibility, styling options, and energy efficiency compared to traditional automotive lighting solutions.

Backlighting for Displays

LED PCBs are commonly used for backlighting LCD and OLED displays in various devices, such as smartphones, tablets, laptops, and televisions. They provide uniform, high-quality illumination while consuming minimal power.

Signage and Advertising

LED PCBs are used in digital signage, billboards, and other advertising displays. They offer bright, eye-catching visuals and the ability to display dynamic content, making them an effective tool for capturing audience attention.

Medical Equipment

LED PCBs are used in various medical devices, such as surgical lighting, endoscopes, and medical monitors. They provide reliable, high-quality illumination and imaging capabilities, which are essential for accurate diagnosis and treatment.

LED PCB Manufacturing Process

The manufacturing process for LED PCBs involves several steps, each critical to ensuring the quality and reliability of the final product. The main steps in the LED PCB manufacturing process include:

PCB Design and Layout

The first step in the LED PCB manufacturing process is designing the circuit and creating the PCB layout using specialized software. This involves selecting the appropriate components, determining their placement, and routing the conductive traces to connect them.

PCB Fabrication

Once the PCB design is finalized, the fabrication process begins. This typically involves the following steps:

- Printing the circuit pattern onto the copper-clad PCB Substrate using photoresist and exposure to UV light.

- Etching away the unwanted copper to create the conductive traces.

- Drilling holes for through-hole components and vias.

- Applying solder mask and silkscreen layers for protection and labeling.

Component Placement

After the PCB fabrication is complete, the electronic components, including LEDs, are placed onto the board. This is typically done using automated pick-and-place machines, which accurately position the components based on the PCB layout.

Soldering

The placed components are then soldered onto the PCB using either wave soldering, reflow soldering, or hand soldering techniques. This process creates a permanent electrical and mechanical connection between the components and the PCB.

Testing and Inspection

After soldering, the LED PCBs undergo thorough testing and inspection to ensure proper functionality, performance, and quality. This may include visual inspections, automated optical inspections (AOI), and electrical testing.

Packaging and Shipping

Finally, the completed LED PCBs are packaged and shipped to the customer or integrated into the final product, depending on the application and manufacturing process.

LED PCB Testing and Quality Control

To ensure the reliability and performance of LED PCBs, various testing and quality control methods are employed throughout the manufacturing process and during the final inspection. Some of the most common testing and quality control methods include:

Visual Inspection

Visual inspection is the most basic form of quality control, involving a manual examination of the LED PCB for any visible defects, such as damaged components, solder bridges, or incorrect component placement.

Automated Optical Inspection (AOI)

AOI uses computer vision and image processing techniques to automatically detect and identify PCB defects, such as missing components, incorrect component polarity, or solder issues. This method is faster and more accurate than manual visual inspection.

In-Circuit Testing (ICT)

ICT involves using specialized probes to test the electrical functionality of individual components and circuits on the LED PCB. This method can detect issues such as short circuits, open circuits, and incorrect component values.

Functional Testing

Functional testing involves powering up the LED PCB and verifying that it performs as intended. This may include testing LED brightness, color, and control functionality, as well as ensuring compatibility with the target application.

Burn-In Testing

Burn-in testing involves operating the LED PCB under controlled conditions, such as elevated temperature and voltage, for an extended period to identify any early failures or performance issues. This method helps to ensure the long-term reliability of the LED PCB.

Future Trends in LED PCB Technology

As technology advances and new applications emerge, LED PCB technology continues to evolve. Some of the current and future trends in LED PCB technology include:

Miniaturization

The demand for smaller, more compact electronic devices is driving the miniaturization of LED PCBs. This involves the use of smaller LEDs, such as chip-scale packages (CSP) and micro-LEDs, as well as advanced PCB fabrication techniques, such as high-density interconnect (HDI) and embedded components.

Flexible and Stretchable LED PCBs

The development of flexible and stretchable LED PCBs is expanding the range of applications for LED technology. These PCBs can conform to various shapes and surfaces, enabling the integration of LEDs into wearable devices, smart textiles, and other innovative products.

Smart LED PCBs

The integration of sensors, microcontrollers, and wireless connectivity into LED PCBs is enabling the development of smart LED systems. These systems can adapt to environmental conditions, respond to user input, and communicate with other devices, opening up new possibilities for intelligent lighting and display applications.

Sustainable and Eco-Friendly Materials

As environmental concerns grow, there is an increasing demand for sustainable and eco-friendly materials in LED PCB manufacturing. This includes the use of recyclable and biodegradable PCB substrates, as well as the development of lead-free and halogen-free manufacturing processes.

Conclusion

LED PCBs are essential components in a wide range of electronic devices, offering energy efficiency, reliability, and versatility. By understanding the types, advantages, design considerations, and manufacturing processes of LED PCBs, engineers and manufacturers can create innovative and high-quality LED solutions for various applications. As technology continues to advance, the future of LED PCBs looks bright, with ongoing developments in miniaturization, flexibility, intelligence, and sustainability.

FAQ

-

What are the main benefits of using LED PCBs in electronic devices?

LED PCBs offer several benefits, including energy efficiency, long lifespan, compact size, design flexibility, and environmental friendliness. These advantages make them a popular choice for a wide range of applications, from general lighting to automotive and medical equipment. -

What factors should be considered when selecting LEDs for a PCB design?

When selecting LEDs for a PCB design, important factors to consider include LED type (SMD or through-hole), color, brightness, viewing angle, and power requirements. The selected LEDs should be compatible with the PCB design and meet the desired performance criteria. -

How does thermal management impact LED PCB performance?

Proper thermal management is crucial for LED PCB performance, as LEDs generate heat during operation. If not effectively dissipated, this heat can negatively impact LED performance and lifespan. LED PCBs should incorporate thermal management techniques, such as heat sinks, thermal vias, and appropriate PCB materials, to maintain optimal LED performance. -

What are some common testing and quality control methods for LED PCBs?

Common testing and quality control methods for LED PCBs include visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and burn-in testing. These methods help to identify defects, verify electrical functionality, and ensure the long-term reliability of the LED PCB. -

What are some emerging trends in LED PCB technology?

Some emerging trends in LED PCB technology include miniaturization, flexible and stretchable LED PCBs, smart LED PCBs with integrated sensors and wireless connectivity, and the use of sustainable and eco-friendly materials in PCB manufacturing. These trends are driven by the demand for smaller, more versatile, and environmentally friendly LED solutions.

| LED PCB Type | Description |

|---|---|

| Single-Sided | Conductive traces and components on only one side of the board. Simple and cost-effective for basic applications. |

| Double-Sided | Conductive traces and components on both sides of the board, connected through plated-through holes (PTHs). Offers higher component density. |

| Multi-Layer | Three or more layers of conductive traces, separated by insulating layers. Highest component density and most complex circuit designs. |

| Flexible | Made of thin, flexible insulating material with conductive traces. Can bend and conform to various shapes. Ideal for wearable electronics. |

| LED PCB Application | Description |

|---|---|

| General Lighting | Indoor and outdoor lighting, task lighting, and decorative lighting. Energy-efficient, long-lasting, and customizable solutions for various settings. |

| Automotive Lighting | Headlights, taillights, interior lighting, and instrument panel backlighting. Improved visibility, styling options, and energy efficiency compared to traditional solutions. |

| Display Backlighting | Backlighting for LCD and OLED displays in smartphones, tablets, laptops, and televisions. Provides uniform, high-quality illumination while consuming minimal power. |

| Signage and Advertising | Digital signage, billboards, and other advertising displays. Offers bright, eye-catching visuals and the ability to display dynamic content. |

| Medical Equipment | Surgical lighting, endoscopes, and medical monitors. Provides reliable, high-quality illumination and imaging capabilities for accurate diagnosis and treatment. |

No responses yet