Understanding the Factors Affecting circuit board cost

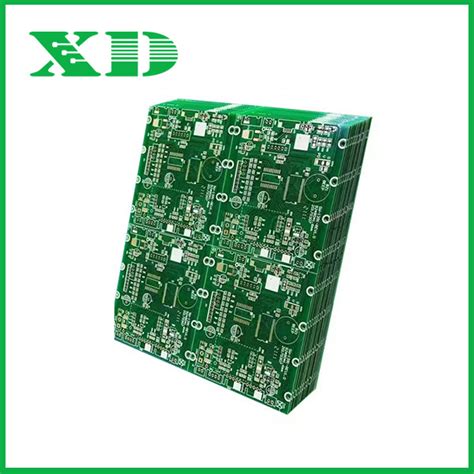

When it comes to creating electronic devices, one of the most crucial components is the circuit board. A circuit board, also known as a printed circuit board (PCB), is the foundation upon which electronic components are mounted and interconnected to form a functional electronic system. The cost of a simple circuit board can vary greatly depending on several factors, such as the size, complexity, materials used, and manufacturing process.

In this article, we will explore the various aspects that influence the cost of a simple circuit board and provide you with a comprehensive understanding of what to expect when budgeting for your electronic projects.

Size and Complexity of the Circuit Board

One of the primary factors that determine the cost of a circuit board is its size and complexity. The larger the board and the more intricate the circuit design, the higher the cost will be. This is because larger boards require more materials and take longer to manufacture, while complex designs demand more precise equipment and skilled labor.

Circuit boards can be categorized into three main types based on their complexity:

-

Single-layer boards: These are the simplest and most cost-effective PCBs, consisting of a single conductive layer. They are suitable for basic electronic projects and low-density designs.

-

Double-layer boards: As the name suggests, these boards have two conductive layers, allowing for more complex circuits and higher component density. Double-layer boards are more expensive than single-layer boards due to the additional materials and manufacturing steps involved.

-

Multi-layer boards: These boards have three or more conductive layers, enabling even more intricate circuit designs and higher component density. Multi-layer boards are the most expensive option, as they require specialized manufacturing processes and materials.

The following table provides a rough estimate of the cost per square inch for different types of circuit boards:

| Board Type | Cost per Square Inch |

|---|---|

| Single-layer | $0.10 – $0.30 |

| Double-layer | $0.20 – $0.60 |

| Multi-layer | $0.50 – $2.00+ |

Keep in mind that these are just estimates, and the actual cost may vary depending on the specific requirements of your project and the manufacturer you choose.

Materials Used in Circuit Board Manufacturing

Another factor that significantly impacts the cost of a circuit board is the materials used in its construction. The most common materials used in PCB manufacturing are:

-

FR-4: This is the most widely used material for PCBs, consisting of a fiberglass substrate with an epoxy resin binder. FR-4 is known for its excellent electrical insulation properties, mechanical strength, and heat resistance. It is also relatively inexpensive, making it a popular choice for most applications.

-

Polyimide: This high-performance material is used in applications that require superior heat resistance and mechanical stability. Polyimide PCBs are more expensive than FR-4 boards due to their advanced properties and more complex manufacturing process.

-

Aluminum: Aluminum PCBs are used in applications that require excellent heat dissipation, such as high-power LED lighting and motor controllers. These boards are more expensive than FR-4 due to the additional cost of the aluminum substrate and the specialized manufacturing process.

-

Flexible PCBs: These boards are made from flexible materials, such as polyimide or polyester, allowing them to bend and conform to various shapes. Flexible PCBs are more expensive than rigid boards due to the special materials and manufacturing techniques required.

The choice of material will depend on the specific requirements of your project, such as the operating temperature, mechanical stress, and electrical performance needed. Working with a knowledgeable PCB manufacturer can help you select the most suitable material for your application while optimizing costs.

Manufacturing Process and Quantity

The manufacturing process and the quantity of boards ordered also play a significant role in determining the cost of a simple circuit board. PCB manufacturing involves several steps, including:

-

Design and layout: The circuit design is created using specialized software, and the layout is optimized for manufacturing.

-

Fabrication: The bare PCB is manufactured using a series of chemical and mechanical processes, such as etching, drilling, and plating.

-

Assembly: The electronic components are soldered onto the board using either through-hole or surface-mount technology (SMT).

-

Testing and inspection: The assembled board undergoes various tests and inspections to ensure functionality and quality.

Each of these steps contributes to the overall cost of the circuit board. However, the cost per board decreases as the quantity ordered increases due to economies of scale. This means that the fixed costs associated with setting up the manufacturing process are spread across a larger number of boards, resulting in a lower unit cost.

The following table provides a rough estimate of the cost per board for different quantities:

| Quantity | Cost per Board |

|---|---|

| 1-10 | $50 – $200+ |

| 11-100 | $10 – $50 |

| 101-1000 | $2 – $10 |

| 1000+ | $0.50 – $2 |

Again, these are just estimates, and the actual cost will depend on the specific details of your project and the manufacturer you work with.

Additional Considerations

In addition to the factors mentioned above, there are a few other considerations that can impact the cost of a simple circuit board:

-

Lead time: The time required to manufacture and deliver your boards can affect the cost. Faster turnaround times often come with a premium price, while longer lead times may result in lower costs.

-

Design services: If you require assistance with circuit design or layout optimization, some manufacturers offer these services for an additional fee. This can be a cost-effective solution for those who lack the expertise or resources to design their own boards.

-

Certifications and standards: Depending on your application, your circuit boards may need to comply with specific industry standards or certifications, such as UL, CE, or RoHS. Meeting these requirements can add to the overall cost of the boards.

-

Shipping and handling: The cost of shipping and handling your circuit boards can vary depending on the location of the manufacturer, the shipping method chosen, and any applicable import duties or taxes.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum order quantity for circuit boards?

A: The minimum order quantity (MOQ) varies among manufacturers but typically ranges from 1 to 100 boards. Some manufacturers specialize in low-volume production and offer lower MOQs, while others focus on high-volume orders and may have higher MOQs. -

Q: How long does it take to manufacture a simple circuit board?

A: The lead time for manufacturing a simple circuit board depends on the complexity of the design, the materials used, and the workload of the manufacturer. Typical lead times range from 1 to 4 weeks, but expedited services may be available for an additional cost. -

Q: Can I save money by designing my own circuit board?

A: Designing your own circuit board can potentially save you money on design services, but it requires expertise and access to the necessary software tools. If you have the skills and resources to design your own board, it can be a cost-effective option. However, working with a professional designer can help optimize your layout and avoid costly mistakes. -

Q: Are there any cost-saving strategies when ordering circuit boards?

A: Yes, there are several ways to reduce the cost of your circuit boards: - Order in larger quantities to take advantage of economies of scale

- Choose a standard board size and material to avoid custom manufacturing fees

- Opt for a longer lead time to reduce production costs

- Minimize the complexity of your design to reduce manufacturing challenges

-

Work with a reputable manufacturer that offers competitive pricing and value-added services

-

Q: How do I choose the right manufacturer for my circuit board project?

A: When selecting a circuit board manufacturer, consider the following factors: - Experience and expertise in manufacturing boards similar to your project

- Quality control processes and certifications

- Pricing and lead times

- Customer support and communication

- Reviews and testimonials from previous clients

By carefully evaluating these factors, you can find a manufacturer that meets your technical requirements, budget, and project timeline.

Conclusion

The cost of a simple circuit board is influenced by several factors, including the size and complexity of the board, the materials used, the manufacturing process, and the quantity ordered. By understanding these factors and working with a reputable manufacturer, you can make informed decisions that balance your project requirements with your budget constraints.

When planning your electronic project, it’s essential to consider not only the cost of the circuit board itself but also any additional expenses, such as design services, certifications, and shipping. By taking a holistic approach to cost management, you can ensure the success of your project while staying within your financial limits.

As technology continues to advance, the cost of circuit board manufacturing may change, and new materials and processes may emerge. Staying informed about industry trends and best practices can help you optimize your circuit board designs and manufacturing strategies for cost-effectiveness and performance.

No responses yet