What are PCB Vias?

PCB vias are conductive pathways that allow electrical signals to travel between different layers of a multi-layer PCB. They are created by drilling small holes through the board and plating them with a conductive material, typically copper. Vias enable designers to create more complex layouts and save space on the board by allowing components and traces to be placed on different layers.

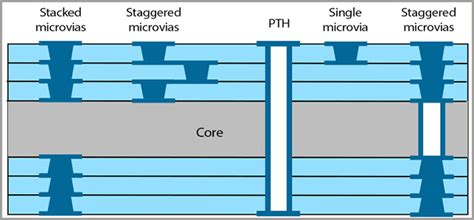

There are several types of vias used in PCB design:

- Through-hole vias: These vias pass through all layers of the PCB, connecting the top and bottom layers.

- Blind vias: These vias connect an outer layer to an inner layer, but do not pass through the entire board.

- Buried vias: These vias connect two or more inner layers, but do not reach the outer layers of the PCB.

- Micro vias: These are small vias, typically less than 0.15mm in diameter, used in high-density designs.

Factors Influencing Via-Related Costs

Several factors can impact the cost of PCBs when vias are involved:

1. Number of Vias

The more vias a PCB has, the higher the cost. Each via requires drilling, plating, and additional processing, which increases the manufacturing time and material costs. Therefore, minimizing the number of vias in a design can help reduce overall expenses.

2. Via Size

The size of the vias can also affect the cost of a PCB. Smaller vias, such as micro vias, require more precise drilling and plating processes, which can increase manufacturing costs. Larger vias are generally easier and cheaper to produce.

3. Via Type

The type of vias used in a PCB design can influence the cost. Through-hole vias are the most common and least expensive, as they are easier to manufacture. Blind and buried vias require more complex processing and are typically more expensive. Micro vias, due to their small size and high precision requirements, can also add to the cost.

4. Layer Count

The number of layers in a PCB directly impacts the cost, and the use of vias is closely related to the layer count. More layers generally require more vias to interconnect them, which can drive up costs. However, using more layers and vias can also help reduce the overall board size, which may offset some of the additional expenses.

5. PCB Material

The choice of PCB material can affect via costs. Some high-performance materials, such as low-loss or high-frequency laminates, may require specialized drilling and plating processes for vias, which can increase manufacturing costs.

Strategies for Optimizing Via Usage and Reducing Costs

To minimize the impact of vias on PCB Costs, designers can employ several strategies:

-

Minimize the number of vias: Carefully plan the component placement and routing to reduce the need for vias. Use techniques like daisy-chaining and component grouping to minimize the number of layers and vias required.

-

Use larger via sizes when possible: When the design allows, opt for larger via sizes to reduce manufacturing complexity and costs. Only use smaller vias, such as micro vias, when absolutely necessary for high-density designs.

-

Avoid blind and buried vias: Stick to through-hole vias whenever possible, as they are the most cost-effective. Only use blind and buried vias when the design requires them for space or performance reasons.

-

Optimize layer stackup: Carefully plan the layer stackup to minimize the number of layers and vias needed. Consider using techniques like via-in-pad or blind vias to reduce the overall layer count.

-

Consider alternative design approaches: In some cases, alternative design techniques, such as using surface-mount components or flexible PCBs, may help reduce the need for vias and lower costs.

Via Cost Comparison

To better understand the impact of vias on PCB costs, let’s compare the prices of different via types and sizes. The following table provides a general overview of the relative costs associated with various via options:

| Via Type | Via Size | Relative Cost |

|---|---|---|

| Through-hole | > 0.3mm | $ |

| Through-hole | 0.2mm – 0.3mm | $$ |

| Blind/Buried | > 0.3mm | $$$ |

| Blind/Buried | 0.2mm – 0.3mm | $$$$ |

| Micro via | < 0.15mm | $$$$$ |

Note: The relative costs are for illustrative purposes only and may vary depending on the manufacturer and specific project requirements.

As the table shows, through-hole vias are generally the most cost-effective option, while micro vias and blind/buried vias with smaller sizes tend to be the most expensive.

Real-World Example

To illustrate the impact of vias on PCB costs, let’s consider a real-world example. Suppose a company needs to manufacture a batch of 1,000 PCBs for a new product. The design team has created two versions of the PCB:

- Version A: A 4-layer PCB with 100 through-hole vias (0.3mm) and 50 micro vias.

- Version B: A 6-layer PCB with 50 through-hole vias (0.3mm) and no micro vias.

After receiving quotes from various PCB manufacturers, the company finds that Version A costs $10 per board, while Version B costs $8 per board. Although Version B has more layers, the reduced number of vias and the absence of micro vias help lower the overall cost.

In this case, choosing Version B would result in a total savings of $2,000 for the entire batch of 1,000 PCBs. This example demonstrates how optimizing via usage can significantly impact the overall cost of PCB manufacturing.

Conclusion

In conclusion, vias do play a role in determining the cost of a PCB. The number, size, and type of vias used in a design can all contribute to the overall manufacturing expenses. However, by carefully planning the PCB layout, minimizing the number of vias, and choosing cost-effective via options, designers can help reduce the impact of vias on the total cost.

It’s essential to find a balance between the technical requirements of the design and the cost considerations. Working closely with PCB manufacturers and discussing via options early in the design process can help optimize the design for cost-effectiveness without compromising functionality.

Frequently Asked Questions (FAQ)

-

Q: Can vias be completely eliminated from a PCB design to reduce costs?

A: In most cases, it is not possible to completely eliminate vias from a PCB design, especially for multi-layer boards. Vias are essential for creating electrical connections between layers and enabling more complex routing. However, minimizing the number of vias and optimizing their usage can help reduce costs. -

Q: Are micro vias always more expensive than regular through-hole vias?

A: Yes, micro vias are generally more expensive than regular through-hole vias. This is because they require more precise drilling and plating processes, which increase manufacturing complexity and costs. However, in some high-density designs, using micro vias may be necessary to achieve the desired functionality and performance. -

Q: Can using more layers in a PCB help reduce via-related costs?

A: Using more layers in a PCB can potentially help reduce via-related costs by allowing more efficient routing and minimizing the total number of vias required. However, adding more layers also increases the overall cost of the PCB. Designers must find a balance between the number of layers and the number of vias to achieve the most cost-effective solution. -

Q: How can I determine the optimal via size for my PCB design?

A: The optimal via size depends on various factors, such as the PCB material, layer count, and the specific design requirements. In general, using larger vias when possible can help reduce manufacturing costs. Consult with your PCB manufacturer to determine the most suitable via sizes for your project, considering both cost and performance factors. -

Q: Are there any alternative technologies that can replace vias in PCB designs?

A: While vias are the most common method for creating electrical connections between layers in a PCB, there are some alternative technologies available. For example, embedded component technology allows components to be placed inside the PCB, reducing the need for vias. Another option is to use flexible PCBs, which can be folded or bent to create connections between layers. However, these alternative technologies may have their own cost implications and design constraints.

No responses yet