Introduction to PCB manufacturing

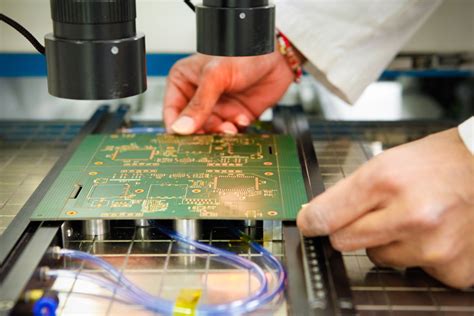

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to medical equipment and aerospace systems. PCBs provide a platform for electronic components to be connected and communicate with each other, enabling complex circuits to function in a compact and efficient manner.

PCB manufacturing is a multi-step process that involves designing the circuit, creating the PCB layout, fabricating the board, and assembling the components. The process requires specialized equipment, materials, and expertise to ensure the highest quality and reliability of the final product.

The Global PCB Market

The global PCB market is a multi-billion dollar industry that is expected to continue growing in the coming years. According to a report by Grand View Research, the global PCB market size was valued at USD 60.2 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2028.

The Asia-Pacific region dominates the global PCB market, with China being the largest producer and consumer of PCBs. Other major players in the Asia-Pacific region include Japan, South Korea, and Taiwan. The North American and European markets are also significant, with the United States and Germany being the largest producers in their respective regions.

The Importance of Domestic PCB Manufacturing

While the Asia-Pacific region dominates the global PCB market, there are several reasons why domestic PCB manufacturing is important for the United States. These include:

-

National Security: PCBs are critical components in many defense and aerospace systems. Relying on foreign suppliers for these components can pose a significant risk to national security.

-

Supply Chain Resilience: The COVID-19 pandemic has highlighted the vulnerabilities of global supply chains. Domestic PCB manufacturing can help ensure a more resilient and secure supply chain for electronic components.

-

Intellectual Property Protection: Domestic PCB manufacturing can help protect intellectual property and prevent the theft of sensitive technologies.

-

Job Creation: Domestic PCB manufacturing can create jobs and stimulate economic growth in the United States.

The State of PCB Manufacturing in the US

History of PCB Manufacturing in the US

The United States was once a leader in PCB manufacturing, with a thriving industry that supplied the defense, aerospace, and consumer electronics sectors. However, over the past few decades, the industry has faced significant challenges, including increased competition from low-cost overseas manufacturers, declining demand from the defense sector, and a shift towards outsourcing by many US electronics companies.

Despite these challenges, the US PCB industry has remained resilient, with a focus on high-end, specialized PCBs for the defense, aerospace, and medical sectors. The industry has also embraced advanced manufacturing technologies, such as 3D printing and flexible PCBs, to remain competitive in the global market.

Current State of the US PCB Industry

According to the IPC, the trade association for the electronics industry, the US PCB industry had a total market value of $3.7 billion in 2020. The industry employs approximately 20,000 people in the United States, with an average annual wage of $65,000.

The US PCB industry is highly fragmented, with many small and medium-sized companies serving niche markets. The industry is also highly regulated, with strict requirements for quality, reliability, and environmental compliance.

| Top US PCB Manufacturers | 2020 Revenue (Millions) |

|---|---|

| TTM Technologies | $2,105.3 |

| Benchmark Electronics | $2,053.1 |

| Sanmina Corporation | $1,704.6 |

| Flex Ltd. | $1,173.5 |

| Jabil Inc. | $864.0 |

Source: IPC, “The North American PCB Industry Report, 2021”

Challenges Facing the US PCB Industry

The US PCB industry faces several challenges that threaten its competitiveness and long-term viability. These include:

-

Skilled Labor Shortage: The industry is facing a shortage of skilled workers, particularly in the areas of engineering and advanced manufacturing.

-

Regulatory Compliance: The industry is subject to strict regulations related to environmental protection, worker safety, and product quality. Compliance with these regulations can be costly and time-consuming.

-

Supply Chain Disruptions: The industry is heavily dependent on imported materials and components, which can be subject to supply chain disruptions and tariffs.

-

Technological Obsolescence: The rapid pace of technological change in the electronics industry can make it difficult for PCB manufacturers to keep up with the latest technologies and processes.

Advantages of US PCB Manufacturing

Despite the challenges facing the industry, there are several advantages to manufacturing PCBs in the United States. These include:

Quality and Reliability

US PCB manufacturers are known for their high-quality and reliable products. The industry is subject to strict quality control standards and regulations, which ensure that PCBs meet the highest standards of performance and reliability.

US PCB manufacturers also have access to advanced manufacturing technologies and processes, such as 3D printing and flexible PCBs, which can improve the quality and functionality of PCBs.

Intellectual Property Protection

Manufacturing PCBs in the United States can help protect intellectual property and prevent the theft of sensitive technologies. US PCB manufacturers are subject to strict intellectual property laws and regulations, which can help prevent the unauthorized use or disclosure of proprietary information.

Customization and Flexibility

US PCB manufacturers are known for their ability to provide customized and flexible solutions to meet the specific needs of their customers. Many US PCB manufacturers specialize in niche markets and applications, such as aerospace, defense, and medical devices, which require highly specialized and customized PCBs.

US PCB manufacturers also have the ability to quickly adapt to changing customer requirements and market conditions, which can be a significant advantage in today’s fast-paced and dynamic business environment.

Proximity to Customers

Manufacturing PCBs in the United States can provide significant advantages in terms of proximity to customers. US-based customers can benefit from faster delivery times, improved communication, and greater collaboration with their PCB suppliers.

Proximity to customers can also facilitate the development of long-term partnerships and strategic relationships, which can help drive innovation and improve the overall competitiveness of the US electronics industry.

Challenges and Opportunities for US PCB Manufacturing

Skilled Labor Shortage

One of the biggest challenges facing the US PCB industry is the shortage of skilled labor, particularly in the areas of engineering and advanced manufacturing. The industry is facing a significant skills gap, with many experienced workers nearing retirement age and a lack of younger workers entering the field.

To address this challenge, the industry is investing in education and training programs to attract and retain skilled workers. Many US PCB manufacturers are partnering with local schools and universities to develop curricula and apprenticeship programs that provide hands-on training and experience in PCB manufacturing.

Regulatory Compliance

The US PCB industry is subject to strict regulations related to environmental protection, worker safety, and product quality. Compliance with these regulations can be costly and time-consuming, particularly for smaller manufacturers with limited resources.

To address this challenge, the industry is investing in new technologies and processes that can help improve efficiency and reduce the cost of compliance. Many US PCB manufacturers are also partnering with industry associations and government agencies to develop best practices and standards for regulatory compliance.

Supply Chain Disruptions

The US PCB industry is heavily dependent on imported materials and components, which can be subject to supply chain disruptions and tariffs. The COVID-19 pandemic has highlighted the vulnerabilities of global supply chains, with many manufacturers facing shortages and delays in critical materials and components.

To address this challenge, many US PCB manufacturers are investing in domestic sourcing and production capabilities to reduce their dependence on foreign suppliers. The industry is also working with government agencies and industry associations to develop more resilient and secure supply chains for critical materials and components.

Technological Obsolescence

The rapid pace of technological change in the electronics industry can make it difficult for PCB manufacturers to keep up with the latest technologies and processes. The industry is facing significant challenges in areas such as miniaturization, high-speed design, and advanced packaging technologies.

To address this challenge, US PCB manufacturers are investing in research and development to stay ahead of the curve and develop new technologies and processes that can meet the evolving needs of their customers. Many manufacturers are also partnering with industry associations and research institutions to collaborate on new technologies and standards.

Frequently Asked Questions (FAQ)

-

Q: What is the current state of the US PCB industry?

A: The US PCB industry had a total market value of $3.7 billion in 2020 and employs approximately 20,000 people in the United States. The industry is highly fragmented, with many small and medium-sized companies serving niche markets. -

Q: What are the advantages of manufacturing PCBs in the United States?

A: Manufacturing PCBs in the United States can provide several advantages, including high quality and reliability, intellectual property protection, customization and flexibility, and proximity to customers. -

Q: What are the biggest challenges facing the US PCB industry?

A: The biggest challenges facing the US PCB industry include a shortage of skilled labor, regulatory compliance, supply chain disruptions, and technological obsolescence. -

Q: How is the US PCB industry addressing the shortage of skilled labor?

A: The US PCB industry is investing in education and training programs to attract and retain skilled workers, including partnering with local schools and universities to develop curricula and apprenticeship programs. -

Q: How is the US PCB industry addressing supply chain disruptions?

A: Many US PCB manufacturers are investing in domestic sourcing and production capabilities to reduce their dependence on foreign suppliers, and working with government agencies and industry associations to develop more resilient and secure supply chains for critical materials and components.

Conclusion

The US PCB industry has a long and proud history of innovation and leadership in the global electronics industry. Despite facing significant challenges in recent years, the industry remains a critical component of the US economy and a key driver of technological advancement.

To remain competitive in the global market, the US PCB industry must continue to invest in advanced manufacturing technologies, develop a skilled workforce, and collaborate with industry partners and government agencies to address regulatory and supply chain challenges.

By leveraging its strengths in quality, reliability, and customization, the US PCB industry can continue to provide high-value solutions to its customers and drive innovation in the electronics industry for years to come.

No responses yet