Understanding FR4 and Its Role in PCBs

FR4 (Flame Retardant 4) is a composite material composed of woven fiberglass cloth with an epoxy resin binder. It is the most widely used insulating substrate material for PCBs due to its excellent mechanical, electrical, and thermal properties. FR4 provides the following benefits:

- High dielectric strength

- Good mechanical strength and dimensional stability

- Excellent moisture and chemical resistance

- Flame retardant properties

- Suitable for a wide range of applications and environments

Standard FR4 Layer Thicknesses

PCBs can have varying numbers of layers, ranging from single-sided boards to complex multi-layer designs. The thickness of each FR4 layer plays a crucial role in determining the overall thickness of the PCB. The standard thicknesses for FR4 layers are:

| Layer Thickness (mm) | Layer Thickness (inches) |

|---|---|

| 0.1 | 0.0039 |

| 0.2 | 0.0079 |

| 0.3 | 0.0118 |

| 0.4 | 0.0157 |

| 0.5 | 0.0197 |

| 0.6 | 0.0236 |

| 0.8 | 0.0315 |

| 1.0 | 0.0394 |

| 1.2 | 0.0472 |

| 1.6 | 0.0630 |

The most commonly used FR4 layer thicknesses are 0.4mm, 0.6mm, 0.8mm, and 1.6mm. These thicknesses provide a good balance between mechanical strength, electrical performance, and manufacturability.

Factors Influencing FR4 Layer Thickness Selection

When choosing the appropriate FR4 layer thickness for a PCB, several factors must be considered:

-

Number of Layers: The total number of layers in a PCB design influences the choice of FR4 layer thickness. As the layer count increases, thinner FR4 layers are often used to keep the overall board thickness within acceptable limits.

-

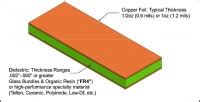

Copper Weight: The weight of the copper foil used for the conductive layers affects the choice of FR4 layer thickness. Thicker copper foils require thicker FR4 layers to maintain the desired dielectric spacing and impedance control.

-

Signal Integrity: For high-speed and high-frequency applications, the thickness of the FR4 layers plays a crucial role in maintaining signal integrity. Thinner layers help reduce dielectric losses and maintain consistent impedance across the board.

-

Mechanical Strength: The overall thickness of the PCB, which is largely determined by the FR4 layer thickness, affects its mechanical strength and rigidity. Thicker boards are generally more robust and less prone to warping or damage during handling and assembly.

-

Thermal Management: The thickness of the FR4 layers can impact the PCB’s thermal management properties. Thicker layers provide better heat dissipation, which is essential for high-power applications or devices operating in harsh environments.

-

Manufacturing Constraints: The choice of FR4 layer thickness must also consider manufacturing capabilities and constraints. Some PCB fabrication houses may have limitations on the minimum or maximum thicknesses they can reliably produce.

Calculating Total PCB thickness

To determine the overall thickness of a PCB, you need to consider the thickness of the FR4 layers, copper layers, and any additional components, such as solder masks or silkscreens. The total PCB thickness can be calculated using the following formula:

Total PCB Thickness = (Number of FR4 Layers × FR4 Layer Thickness) + (Number of Copper Layers × Copper Thickness) + Additional Components

For example, consider a 4-layer PCB with 0.6mm FR4 layers, 1oz copper foil (0.035mm thick), and a solder mask on both sides (0.025mm each):

Total PCB Thickness = (3 × 0.6mm) + (4 × 0.035mm) + (2 × 0.025mm)

= 1.8mm + 0.14mm + 0.05mm

= 1.99mm (approximately 2mm)

Impact of FR4 Layer Thickness on PCB Performance

The thickness of the FR4 layers in a PCB has a significant impact on its overall performance:

-

Signal Integrity: Thinner FR4 layers help maintain better signal integrity by reducing dielectric losses and ensuring consistent impedance across the board. This is particularly important for high-speed and high-frequency applications, such as high-speed digital interfaces, RF circuits, and microwave devices.

-

Crosstalk and EMI: The spacing between conductive layers, which is determined by the FR4 layer thickness, affects the level of crosstalk and electromagnetic interference (EMI) in a PCB. Thicker FR4 layers provide better isolation between signals, reducing crosstalk and EMI.

-

Power Integrity: The thickness of the FR4 layers can impact the power delivery network (PDN) of a PCB. Thicker layers offer lower resistance and inductance, helping to maintain a stable power supply and minimize voltage drops across the board.

-

Thermal Management: Thicker FR4 layers provide better thermal conductivity, allowing for more efficient heat dissipation from components and copper traces. This is crucial for high-power applications or devices operating in extreme temperature environments.

-

Mechanical Strength: The overall thickness of the PCB, largely determined by the FR4 layer thickness, affects its mechanical strength and durability. Thicker boards are generally more robust and less susceptible to warping, bending, or damage during handling, assembly, and operation.

FR4 Layer Thickness and Manufacturing Considerations

The choice of FR4 layer thickness also has implications for the manufacturing process and cost of PCBs:

-

Lamination Process: The thickness of the FR4 layers affects the lamination process, where the layers are bonded together under heat and pressure. Thicker layers require longer lamination cycles and may be more challenging to bond consistently.

-

Drilling and Plating: The thickness of the FR4 layers impacts the drilling and plating processes. Thicker boards require longer drill bits and more precise control to ensure accurate and consistent hole formation. Plating through-holes in thicker boards also takes longer and may require specialized equipment.

-

Etching and Soldermask Application: The FR4 layer thickness can affect the etching process, as thicker layers may require longer etching times or more precise control to achieve the desired trace geometries. Applying soldermask to thicker boards may also be more challenging, as it requires a more consistent coating to ensure adequate coverage and protection.

-

Cost: The choice of FR4 layer thickness can impact the overall cost of PCB manufacturing. Thicker layers require more raw materials and may have higher processing costs due to longer lamination, drilling, and plating cycles. However, the cost impact must be balanced against the performance and reliability requirements of the application.

FAQ

-

What is the most common FR4 layer thickness used in PCBs?

The most common FR4 layer thicknesses used in PCBs are 0.4mm, 0.6mm, 0.8mm, and 1.6mm. These thicknesses provide a good balance between performance, manufacturability, and cost for a wide range of applications. -

Can I use different FR4 layer thicknesses within the same PCB?

Yes, it is possible to use different FR4 layer thicknesses within the same PCB, creating a hybrid stackup. This can be useful when certain layers require specific thicknesses for impedance control or signal integrity purposes, while others can use standard thicknesses for cost or manufacturability reasons. However, hybrid stackups may increase the complexity and cost of the manufacturing process. -

How does the FR4 layer thickness affect the impedance of a PCB?

The thickness of the FR4 layers directly affects the impedance of a PCB. Thinner layers result in higher impedance, while thicker layers lead to lower impedance. The relationship between FR4 layer thickness and impedance is important for high-speed and high-frequency applications, where maintaining consistent impedance across the board is critical for signal integrity and performance. -

What are the limitations on the minimum and maximum FR4 layer thicknesses?

The minimum and maximum FR4 layer thicknesses are typically limited by the manufacturing capabilities of PCB fabrication houses. Most manufacturers can reliably produce FR4 layers as thin as 0.1mm and as thick as 1.6mm. However, some specialized facilities may be able to accommodate thinner or thicker layers, depending on the specific requirements of the application. -

How do I choose the right FR4 layer thickness for my PCB design?

Choosing the right FR4 layer thickness for a PCB design involves considering several factors, including the number of layers, copper weight, signal integrity requirements, mechanical strength, thermal management, and manufacturing constraints. It is essential to consult with the PCB fabrication house and discuss the specific requirements and trade-offs of the application to determine the most suitable FR4 layer thickness for the design.

Conclusion

The thickness of FR4 layers in a PCB plays a crucial role in determining the board’s performance, reliability, and manufacturability. By understanding the standard FR4 layer thicknesses, their impact on signal integrity, mechanical strength, thermal management, and manufacturing processes, designers can make informed decisions when selecting the appropriate thickness for their PCB designs.

When choosing the FR4 layer thickness, it is essential to consider the specific requirements of the application, such as the number of layers, copper weight, signal integrity, and thermal management needs. Balancing these factors with manufacturing constraints and cost implications is key to achieving the optimal balance between performance and affordability.

Consulting with experienced PCB fabrication houses and discussing the specific needs of the project can help designers navigate the trade-offs and select the most suitable FR4 layer thickness for their PCB designs. By making informed choices and collaborating with manufacturing partners, designers can ensure that their PCBs meet the desired performance, reliability, and cost targets, ultimately contributing to the success of their electronic products.

No responses yet