Understanding PCB sizes

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for electrical components to be mounted and interconnected. The size of a PCB can vary greatly depending on the application and the complexity of the circuit design. In this article, we will explore the factors that determine PCB size, the common sizes available, and the considerations for choosing the appropriate size for your project.

Factors Affecting PCB Size

Several factors influence the size of a PCB, including:

-

Component Count: The number of components required for a particular circuit design directly impacts the size of the PCB. More components generally require a larger board to accommodate them.

-

Component Size: The physical dimensions of the components used in the circuit also affect the PCB size. Larger components, such as transformers or high-power resistors, may necessitate a larger board.

-

Trace Width and Spacing: The width of the conductive traces and the spacing between them can influence the overall size of the PCB. Wider traces and larger spacing are often required for high-current or high-voltage applications, resulting in a larger board.

-

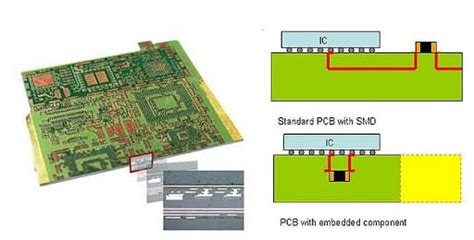

Layer Count: The number of layers in a PCB can impact its size. Multi-layer boards allow for more compact designs by utilizing the vertical space, while single-layer boards may require a larger surface area to accommodate the same number of components and traces.

-

Manufacturing Constraints: PCB manufacturers have specific capabilities and limitations that can affect the maximum and minimum sizes of PCBs they can produce. These constraints may vary depending on the manufacturing process and equipment used.

Common PCB Sizes

PCBs come in various standard sizes to cater to different applications and industries. Some common PCB sizes include:

| Size | Dimensions (mm) | Typical Applications |

|---|---|---|

| Small | 25 x 25 | Wearables, IoT devices, small sensors |

| Medium | 50 x 50 | Smartphones, tablets, portable electronics |

| Large | 100 x 100 | Laptops, desktops, industrial controllers |

| Extra Large | 200 x 200 | Servers, aerospace, military equipment |

Table 1: Common PCB Sizes and Their Applications

It’s important to note that these are just examples, and PCBs can be manufactured in various custom sizes to meet specific requirements.

PCB Size Limitations

While PCBs can be manufactured in a wide range of sizes, there are certain limitations to consider:

Maximum PCB Size

The maximum size of a PCB is primarily determined by the manufacturing capabilities of the PCB fabricator. Most PCB manufacturers can produce boards up to a certain size, typically around 500mm x 500mm (19.7″ x 19.7″). However, some specialized manufacturers may be able to accommodate larger sizes, such as 1000mm x 1000mm (39.4″ x 39.4″) or even larger.

It’s crucial to consult with your chosen PCB manufacturer to understand their specific size limitations and any additional requirements for large-scale PCBs.

Minimum PCB Size

On the other end of the spectrum, there are also limitations to how small a PCB can be manufactured. The minimum size of a PCB is determined by several factors, including:

-

Component Size: The smallest available component sizes dictate the minimum PCB size. As component technology advances, smaller components enable the design of more compact PCBs.

-

Trace Width and Spacing: The minimum trace width and spacing that can be reliably manufactured limit the minimum PCB size. Smaller traces and tighter spacing allow for more compact designs but may increase manufacturing costs and complexity.

-

Manufacturing Process: Different PCB manufacturing processes have varying capabilities in terms of minimum feature sizes. Advanced processes, such as high-density interconnect (HDI) PCBs, can produce smaller boards with finer traces and spacing.

Typically, the minimum PCB size that can be manufactured reliably is around 5mm x 5mm (0.2″ x 0.2″). However, this may vary depending on the specific requirements and the chosen manufacturing process.

Design Considerations for PCB Size

When designing a PCB, several factors should be considered to determine the appropriate size:

Functionality and Components

The primary consideration for PCB size is the functionality of the circuit and the components required to achieve it. A thorough understanding of the circuit design and component selection is essential to estimate the necessary board size.

Enclosure and Mounting

The PCB size must be compatible with the intended enclosure or mounting system. Consider the available space within the enclosure and any mounting holes or features that need to be accommodated on the PCB.

Manufacturing Cost

PCB size directly impacts manufacturing costs. Larger boards require more material and may incur higher manufacturing fees. However, attempting to minimize the PCB size excessively can also increase costs due to the need for more advanced manufacturing processes or smaller components.

Assembly and Maintenance

The PCB size should allow for easy assembly and maintenance. Adequate space between components facilitates soldering and rework processes. Cramped layouts can lead to difficulties in assembly and repair, increasing the risk of errors and damage.

FAQ

- What is the largest PCB size that can be manufactured?

-

The largest PCB size that can be manufactured depends on the capabilities of the PCB fabricator. Most manufacturers can produce boards up to around 500mm x 500mm (19.7″ x 19.7″), while some specialized manufacturers may accommodate larger sizes up to 1000mm x 1000mm (39.4″ x 39.4″) or even larger.

-

What factors determine the minimum PCB size?

-

The minimum PCB size is determined by factors such as the smallest available component sizes, the minimum trace width and spacing that can be reliably manufactured, and the capabilities of the chosen manufacturing process. Typically, the minimum PCB size is around 5mm x 5mm (0.2″ x 0.2″).

-

How does PCB size affect manufacturing costs?

-

PCB size directly impacts manufacturing costs. Larger boards require more material and may incur higher manufacturing fees. However, excessively minimizing the PCB size can also increase costs due to the need for more advanced manufacturing processes or smaller components.

-

Can I design a PCB in any custom size?

-

Yes, PCBs can be designed and manufactured in various custom sizes to meet specific requirements. However, it’s important to consult with your chosen PCB manufacturer to understand their specific size limitations and any additional requirements for custom-sized PCBs.

-

What should I consider when choosing the appropriate PCB size for my project?

- When choosing the appropriate PCB size, consider factors such as the functionality and components required, compatibility with the intended enclosure or mounting system, manufacturing costs, and ease of assembly and maintenance. Strike a balance between these factors to determine the optimal PCB size for your specific project.

Conclusion

The size of a PCB can vary greatly depending on the application, complexity of the circuit design, and manufacturing constraints. Factors such as component count, component size, trace width and spacing, layer count, and manufacturing capabilities all influence the final PCB size.

While PCBs can be manufactured in a wide range of sizes, there are limitations to both the maximum and minimum sizes achievable. The maximum PCB size is primarily determined by the manufacturing capabilities of the PCB fabricator, while the minimum size is limited by factors such as component sizes, trace width and spacing, and the chosen manufacturing process.

When designing a PCB, it’s essential to consider the functionality and components required, compatibility with the enclosure or mounting system, manufacturing costs, and ease of assembly and maintenance. By striking a balance between these factors, you can determine the appropriate PCB size for your specific project.

Consulting with your chosen PCB manufacturer is crucial to understand their specific size limitations and any additional requirements for custom-sized PCBs. By working closely with your manufacturer and considering the various factors that influence PCB size, you can ensure that your PCB design is optimized for functionality, manufacturability, and cost-effectiveness.

No responses yet