Introduction

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, providing a platform for electrical connections and mechanical support. To ensure the safety and functionality of these delicate boards during transportation and storage, proper packaging is crucial. In this article, we will explore the various materials used for PCB Packaging, their properties, and their suitability for different applications.

Types of PCB Packaging Materials

1. Antistatic Bags

1.1. Composition and Properties

Antistatic bags, also known as ESD (Electrostatic Discharge) bags, are commonly used for PCB packaging. These bags are made from a multilayer material that typically consists of polyethylene (PE) or polyester (PET) with a metal or carbon coating. The conductive layer helps dissipate any static charge buildup, preventing damage to sensitive electronic components.

1.2. Advantages

- Provides excellent protection against ESD

- Available in various sizes to accommodate different PCB dimensions

- Transparent, allowing for easy identification of contents

- Resealable for added convenience

1.3. Disadvantages

- Not suitable for long-term storage due to limited moisture protection

- May not provide sufficient physical protection against impacts or crushing

2. Vacuum-Sealed Bags

2.1. Composition and Properties

Vacuum-sealed bags are made from a combination of materials, such as nylon, polyethylene, or aluminum foil. These bags are designed to remove air from the packaging, creating a tight seal around the PCB. This method helps protect the board from moisture, dust, and other contaminants.

2.2. Advantages

- Excellent protection against moisture and humidity

- Reduces the risk of oxidation and corrosion

- Compact packaging, saving storage space

- Suitable for long-term storage

2.3. Disadvantages

- Requires specialized equipment for sealing

- May not provide adequate ESD protection unless combined with antistatic materials

- Opening the bag compromises the seal, requiring resealing for continued protection

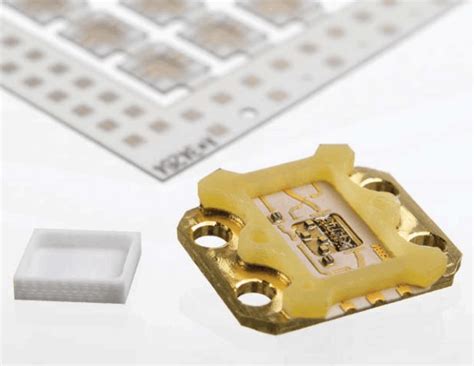

3. Foam Packaging

3.1. Composition and Properties

Foam packaging materials, such as polyethylene foam or antistatic foam, are used to cushion and protect PCBs from physical damage during transportation. These materials are lightweight, durable, and can be easily cut to fit the specific dimensions of the PCB.

3.2. Advantages

- Provides excellent physical protection against impacts, vibrations, and crushing

- Available in various densities to accommodate different levels of protection

- Can be combined with antistatic bags for added ESD protection

- Reusable and recyclable

3.3. Disadvantages

- May not provide sufficient protection against moisture and humidity

- Can be bulky, increasing packaging size and shipping costs

- Some foam materials may generate static charges, requiring antistatic properties

4. Corrugated Cardboard Boxes

4.1. Composition and Properties

Corrugated cardboard boxes are widely used for PCB packaging due to their durability, affordability, and versatility. These boxes are made from multiple layers of paper, with a fluted middle layer that provides cushioning and structural support.

4.2. Advantages

- Strong and durable, offering excellent physical protection

- Customizable to fit specific PCB sizes and shapes

- Can be combined with other packaging materials for added protection

- Recyclable and environmentally friendly

4.3. Disadvantages

- Does not provide ESD protection unless combined with antistatic materials

- May not be suitable for long-term storage in humid environments

- Requires additional packaging materials for cushioning and moisture protection

Factors to Consider When Choosing PCB Packaging Materials

1. Sensitivity of the PCB

The choice of packaging material depends on the sensitivity of the PCB to various environmental factors. For example, PCBs with sensitive components, such as those used in medical devices or aerospace applications, may require more robust packaging to prevent damage from ESD, moisture, or physical impacts.

2. Storage and Transportation Conditions

The expected storage and transportation conditions should be considered when selecting PCB packaging materials. If the PCBs will be stored for an extended period or transported through harsh environments, moisture-resistant and durable packaging materials, such as vacuum-sealed bags or corrugated cardboard boxes with additional protective layers, may be necessary.

3. Cost and Availability

The cost and availability of packaging materials should also be taken into account. While some materials, such as antistatic bags, are widely available and relatively inexpensive, others, like specialized vacuum-sealing equipment, may be more costly and harder to obtain. It is essential to find a balance between the required level of protection and the cost-effectiveness of the packaging solution.

4. Environmental Impact

With growing concerns about sustainability and environmental responsibility, the environmental impact of packaging materials should not be overlooked. Opting for recyclable or biodegradable materials, such as corrugated cardboard or certain types of foam, can help reduce waste and minimize the ecological footprint of PCB packaging.

Best Practices for PCB Packaging

1. Use Multiple Layers of Protection

Combining different packaging materials can provide optimal protection for PCBs. For example, placing a PCB in an antistatic bag before cushioning it with foam and placing it in a corrugated cardboard box offers protection against ESD, physical damage, and moisture.

2. Ensure Proper Sealing

When using packaging materials like antistatic or vacuum-sealed bags, ensuring a proper seal is crucial. Any gaps or openings in the packaging can compromise the protective properties, exposing the PCB to potential damage. Follow the manufacturer’s instructions for sealing and use the appropriate equipment, such as heat sealers or vacuum sealers, when necessary.

3. Label the Packaging

Clearly labeling the PCB packaging is essential for easy identification and tracking. Include relevant information such as the PCB type, revision number, date of packaging, and any special handling instructions. This practice helps streamline inventory management and ensures that the correct PCBs are used for their intended applications.

4. Handle with Care

Even with proper packaging, PCBs should be handled with care to minimize the risk of damage. When removing PCBs from their packaging or handling them during assembly, use appropriate tools and techniques, such as ESD-safe gloves or tweezers, to prevent accidental damage or contamination.

Table: Comparison of PCB Packaging Materials

| Material | ESD Protection | Moisture Protection | Physical Protection | Cost |

|---|---|---|---|---|

| Antistatic Bags | Excellent | Poor | Poor | Low |

| Vacuum-Sealed Bags | Poor* | Excellent | Moderate | Moderate |

| Foam Packaging | Moderate* | Poor | Excellent | Moderate |

| Corrugated Cardboard Boxes | Poor* | Moderate | Excellent | Low |

*Can be improved by combining with other materials

Frequently Asked Questions (FAQ)

1. Can I reuse PCB packaging materials?

Some PCB packaging materials, such as corrugated cardboard boxes and certain types of foam, can be reused if they are in good condition and have not been contaminated. However, antistatic bags and vacuum-sealed bags should not be reused once opened, as their protective properties may be compromised.

2. How long can I store PCBs in their packaging?

The storage duration depends on the type of packaging material and the storage conditions. PCBs in vacuum-sealed bags can be stored for extended periods, often up to several years, if kept in a cool, dry environment. PCBs in antistatic bags or foam packaging may have a shorter storage life, typically up to a few months, before needing to be inspected or repackaged.

3. Can I use regular plastic bags for PCB packaging?

No, regular plastic bags should not be used for PCB packaging as they do not provide any ESD protection and may even generate static charges that can damage sensitive components. Always use packaging materials specifically designed for PCBs, such as antistatic bags or ESD-safe foam.

4. How do I choose the right size of packaging for my PCBs?

When selecting packaging materials, consider the dimensions of your PCBs and choose bags, boxes, or foam that can comfortably accommodate them. Ensure that there is enough space for cushioning materials, if necessary, but avoid excessively large packaging, as it may increase shipping costs and waste.

5. Are there any eco-friendly options for PCB packaging?

Yes, there are eco-friendly options available for PCB packaging. Some manufacturers offer biodegradable or recyclable packaging materials, such as corrugated cardboard made from recycled paper or biodegradable foam. Additionally, opting for reusable packaging materials, like certain types of foam or boxes, can help reduce waste and minimize environmental impact.

Conclusion

Selecting the appropriate packaging materials for PCBs is essential to ensure their protection during storage and transportation. Various materials, such as antistatic bags, vacuum-sealed bags, foam packaging, and corrugated cardboard boxes, offer different levels of protection against ESD, moisture, and physical damage. When choosing packaging materials, consider factors such as the sensitivity of the PCB, storage and transportation conditions, cost, and environmental impact. By implementing best practices and using the right combination of packaging materials, you can effectively protect your PCBs and maintain their functionality until they are ready for use.

No responses yet