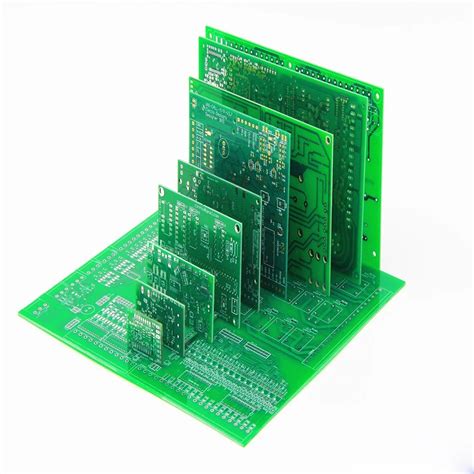

What is FR4 PCB?

FR4 PCB is a type of printed circuit board material that is made from a composite of fiberglass cloth and epoxy resin. The fiberglass cloth provides mechanical strength and stability, while the epoxy resin acts as a binder and insulator. The “FR” in FR4 stands for “Flame Retardant,” indicating that the material has been treated to reduce its flammability.

Properties of FR4 PCB

FR4 PCB possesses several key properties that make it suitable for various applications:

- High mechanical strength and stiffness

- Excellent electrical insulation

- Good thermal stability

- Flame retardancy

- Moisture resistance

- Dimensional stability

- Suitable for high-frequency applications

Applications of FR4 PCB

Due to its desirable properties, FR4 PCB is used in a wide range of industries and applications, such as:

- Consumer electronics (smartphones, laptops, televisions)

- Automotive electronics (engine control units, infotainment systems)

- Industrial equipment (power supplies, motor controllers)

- Medical devices (patient monitors, diagnostic equipment)

- Telecommunications (routers, switches, base stations)

- Aerospace and defense (avionics, radar systems)

Major Manufacturers of FR4 PCB Material

Several companies worldwide manufacture FR4 PCB material. Some of the leading manufacturers include:

1. Panasonic Corporation

Panasonic Corporation is a Japanese multinational electronics company that offers a wide range of FR4 PCB materials under its “Megtron” brand. Their products are known for their high performance, reliability, and consistency.

2. Isola Group

Isola Group is a global leader in the manufacture of high-performance laminate materials for PCBs. They offer a variety of FR4 PCB materials, including their flagship product, IS410, which is designed for high-speed digital applications.

3. Nanya Plastics Corporation

Nanya Plastics Corporation is a Taiwanese company that specializes in the production of PCB materials, including FR4. They offer a range of FR4 products with different glass transition temperatures (Tg) and dielectric constants to cater to various application requirements.

4. Shengyi Technology Co., Ltd.

Shengyi Technology Co., Ltd. is a Chinese manufacturer of PCB materials, including FR4. They have a strong presence in the domestic market and also export their products to other countries. Their FR4 materials are known for their consistency and reliability.

5. Kingboard Laminates Holdings Ltd.

Kingboard Laminates Holdings Ltd. is a leading manufacturer of PCB laminates in China. They offer a wide range of FR4 PCB materials, including halogen-free and high-Tg variants, to meet the diverse needs of their customers.

| Manufacturer | Country | Key Products |

|---|---|---|

| Panasonic Corporation | Japan | Megtron series (Megtron 4, Megtron 6, etc.) |

| Isola Group | USA | IS410, IS400, FR408HR |

| Nanya Plastics Corporation | Taiwan | NP-175, NP-180, NP-200 |

| Shengyi Technology Co., Ltd. | China | S1141, S1170, S1000-2 |

| Kingboard Laminates Holdings Ltd. | China | KB6160, KB6150, KB6165 |

Frequently Asked Questions (FAQ)

1. What is the difference between FR4 and other PCB materials?

FR4 is a specific type of PCB material that is made from fiberglass cloth and epoxy resin. It offers a balance of good mechanical, electrical, and thermal properties. Other PCB materials, such as polyimide or PTFE, may offer higher performance in specific areas but at a higher cost.

2. Can FR4 PCB be used for high-frequency applications?

Yes, FR4 PCB can be used for high-frequency applications up to a certain limit. The standard FR4 material is suitable for applications up to a few gigahertz. For higher frequencies, specialized variants of FR4, such as high-speed or low-loss materials, may be required.

3. Is FR4 PCB environmentally friendly?

Traditional FR4 PCB materials contain halogenated flame retardants, which can be harmful to the environment. However, many manufacturers now offer halogen-free variants of FR4 that are more eco-friendly. These materials use alternative flame retardants that are less toxic and have a lower environmental impact.

4. How does the glass transition temperature (Tg) affect FR4 PCB performance?

The glass transition temperature (Tg) is the temperature at which the FR4 material transitions from a rigid, glassy state to a softer, rubbery state. A higher Tg indicates better thermal stability and resistance to deformation at elevated temperatures. For applications that involve high operating temperatures or soldering processes, a higher Tg FR4 material is often preferred.

5. Can FR4 PCB be used in flexible circuits?

Standard FR4 PCB material is not suitable for flexible circuits due to its rigid nature. However, some manufacturers offer flexible variants of FR4, such as FR4-Flex or Flexible FR4, which can be used in applications that require a certain degree of flexibility. These materials typically have a reduced thickness and may use a modified resin system to enhance flexibility.

Conclusion

FR4 PCB is a versatile and widely used material in the electronics industry, offering a balanced set of properties that make it suitable for a wide range of applications. Several major manufacturers worldwide produce FR4 PCB material, each with their own unique product offerings and specializations. When selecting an FR4 PCB material for a specific application, it is essential to consider factors such as the required electrical and thermal performance, environmental considerations, and cost. By understanding the properties and manufacturers of FR4 PCB material, engineers and designers can make informed decisions to ensure the optimal performance and reliability of their electronic products.

No responses yet