Types of PCB Materials

There are several types of materials used in PCB manufacturing, each with its own unique properties and characteristics. The most common PCB materials include:

- FR-4

- Polyimide

- Teflon

- Ceramic

- Aluminum

- Copper

FR-4

FR-4 is the most widely used material in PCB manufacturing. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. FR-4 has excellent mechanical and electrical properties, making it suitable for a wide range of applications. It has good thermal stability, high dielectric strength, and low moisture absorption.

| Property | Value |

|---|---|

| Dielectric Constant | 4.5 |

| Dissipation Factor | 0.02 |

| Thermal Conductivity | 0.3 W/mK |

| Tensile Strength | 415 MPa |

| Flexural Strength | 415 MPa |

| Moisture Absorption | 0.15% |

Polyimide

Polyimide is a high-performance polymer material used in PCB manufacturing. It has excellent thermal and chemical stability, making it suitable for high-temperature applications. Polyimide has a low dielectric constant and low dissipation factor, making it suitable for high-frequency applications.

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 |

| Dissipation Factor | 0.002 |

| Thermal Conductivity | 0.2 W/mK |

| Tensile Strength | 231 MPa |

| Flexural Strength | 270 MPa |

| Moisture Absorption | 0.4% |

Teflon

Teflon, also known as PTFE (Polytetrafluoroethylene), is a high-performance polymer material used in PCB manufacturing. It has excellent chemical resistance, low dielectric constant, and low dissipation factor. Teflon is suitable for high-frequency and high-temperature applications.

| Property | Value |

|---|---|

| Dielectric Constant | 2.1 |

| Dissipation Factor | 0.0002 |

| Thermal Conductivity | 0.25 W/mK |

| Tensile Strength | 20 MPa |

| Flexural Strength | 17 MPa |

| Moisture Absorption | <0.01% |

Ceramic

Ceramic materials are used in PCB manufacturing for high-frequency and high-temperature applications. They have excellent thermal and chemical stability, low dielectric constant, and low dissipation factor. Alumina (Al2O3) and Beryllia (BeO) are the most common ceramic materials used in PCB manufacturing.

| Property | Alumina | Beryllia |

|---|---|---|

| Dielectric Constant | 9.9 | 6.7 |

| Dissipation Factor | 0.0001 | 0.0004 |

| Thermal Conductivity | 25 W/mK | 270 W/mK |

| Flexural Strength | 380 MPa | 230 MPa |

| Moisture Absorption | 0% | 0% |

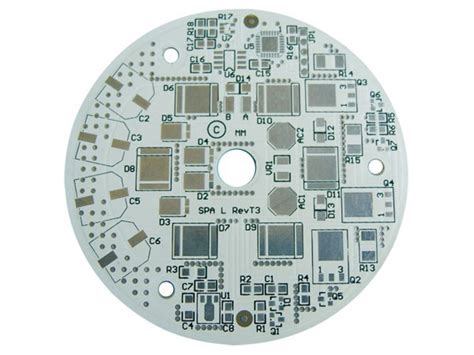

Aluminum

Aluminum is used as a substrate material in PCB manufacturing for high-power applications. It has excellent thermal conductivity, allowing efficient heat dissipation from electronic components. Aluminum PCBs are commonly used in LED lighting, power electronics, and automotive applications.

| Property | Value |

|---|---|

| Thermal Conductivity | 205 W/mK |

| Tensile Strength | 90 MPa |

| Yield Strength | 35 MPa |

| Elongation | 20% |

| Density | 2.7 g/cm³ |

Copper

Copper is the most common conductive material used in PCB manufacturing. It is used for creating the conductive traces and pads on the PCB. Copper has excellent electrical conductivity, thermal conductivity, and resistance to corrosion. The thickness of the copper layer determines the current carrying capacity of the PCB.

| Property | Value |

|---|---|

| Electrical Conductivity | 58.7 MS/m |

| Thermal Conductivity | 386 W/mK |

| Tensile Strength | 210 MPa |

| Yield Strength | 70 MPa |

| Elongation | 45% |

| Density | 8.96 g/cm³ |

PCB Manufacturing Process

The PCB manufacturing process involves several steps, each utilizing different raw materials. The main steps in PCB manufacturing are:

- Substrate Preparation

- Copper Cladding

- Photoresist Application

- Exposure and Development

- Etching

- Solder Mask Application

- Surface Finish

- Drilling and Routing

- Electrical Testing

Substrate Preparation

The first step in PCB manufacturing is substrate preparation. The substrate material, such as FR-4 or polyimide, is cut to the desired size and shape. The substrate is then cleaned to remove any contaminants and roughened to improve adhesion of the copper layer.

Copper Cladding

After substrate preparation, a thin layer of copper is applied to the substrate. This is typically done using electrodeposition or lamination. In electrodeposition, the substrate is immersed in a copper sulfate solution and an electric current is applied, causing the copper to deposit on the substrate surface. In lamination, a copper foil is bonded to the substrate using heat and pressure.

Photoresist Application

A photoresist layer is applied to the copper-clad substrate. The photoresist is a light-sensitive polymer that hardens when exposed to UV light. The photoresist is applied using a spin coating process, where the substrate is spun at high speed while the photoresist is dispensed onto the surface.

Exposure and Development

The photoresist-coated substrate is then exposed to UV light through a photomask. The photomask contains the desired circuit pattern, allowing UV light to pass through and harden the photoresist in the exposed areas. The unexposed areas of the photoresist are then removed using a developer solution, leaving the desired circuit pattern on the copper layer.

Etching

The exposed copper areas are then etched away using a chemical etching process. The most common etchant used is ferric chloride. The etching process removes the unwanted copper, leaving only the desired circuit pattern on the substrate.

Solder Mask Application

A solder mask layer is applied to the PCB to protect the copper traces from oxidation and prevent solder bridges during the soldering process. The solder mask is typically a green or blue polymer material that is applied using screen printing or photoimaging.

Surface Finish

A surface finish is applied to the exposed copper areas to improve solderability and protect the copper from oxidation. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Drilling and Routing

Holes are drilled in the PCB for through-hole components and vias. The PCB is then routed to the desired shape using a CNC machine.

Electrical Testing

Finally, the PCB undergoes electrical testing to ensure that it meets the required specifications. This includes continuity testing, insulation resistance testing, and high-potential testing.

Frequently Asked Questions (FAQ)

- What is the most common substrate material used in PCB manufacturing?

-

FR-4 is the most widely used substrate material in PCB manufacturing due to its excellent mechanical and electrical properties.

-

What is the purpose of the solder mask layer in PCB manufacturing?

-

The solder mask layer protects the copper traces from oxidation and prevents solder bridges during the soldering process. It also provides insulation between adjacent traces.

-

What is the difference between HASL and ENIG surface finishes?

-

HASL (Hot Air Solder Leveling) is a surface finish where the PCB is dipped in molten solder and then leveled using hot air. ENIG (Electroless Nickel Immersion Gold) is a surface finish where a layer of nickel is deposited on the copper, followed by a thin layer of gold. ENIG provides better flatness and solderability compared to HASL.

-

What is the purpose of drilling holes in PCBs?

-

Holes are drilled in PCBs to accommodate through-hole components and create vias. Through-hole components are inserted into the holes and soldered on the opposite side of the board. Vias are used to connect traces on different layers of the PCB.

-

What is the role of copper in PCB manufacturing?

- Copper is used as the conductive material in PCB manufacturing. It is used to create the traces and pads that carry electrical signals between components. The thickness of the copper layer determines the current carrying capacity of the PCB.

Conclusion

PCB manufacturing involves the use of various raw materials, each serving a specific purpose in the production process. FR-4 is the most common substrate material, providing excellent mechanical and electrical properties. Copper is the primary conductive material used for creating traces and pads. Other materials such as polyimide, Teflon, ceramic, and aluminum are used for specialized applications requiring high-temperature stability, low dielectric constant, or efficient heat dissipation.

The PCB manufacturing process involves several steps, including substrate preparation, copper cladding, photoresist application, exposure and development, etching, solder mask application, surface finish, drilling and routing, and electrical testing. Each step utilizes specific raw materials and processes to create the final PCB product.

Understanding the properties and characteristics of PCB materials is crucial for designers and manufacturers to select the appropriate materials for their specific applications. By choosing the right materials and following proper manufacturing processes, high-quality and reliable PCBs can be produced for a wide range of electronic devices.

No responses yet