Understanding the Dielectric constant

The dielectric constant, also known as relative permittivity (εr), is a measure of a material’s ability to store electrical energy in an electric field. It is the ratio of the permittivity of a substance to the permittivity of a vacuum. The dielectric constant of a material determines how much electrical energy can be stored in that material when an electric field is applied.

In the context of PCBs, the dielectric constant of the substrate material, such as FR4, affects the signal propagation, impedance, and capacitance of the traces on the board. A lower dielectric constant generally results in faster signal propagation, lower signal distortion, and reduced crosstalk between adjacent traces.

Dielectric Constant Formula

The dielectric constant is a dimensionless quantity and is represented by the following formula:

εr = ε / ε0

Where:

– εr is the dielectric constant (relative permittivity)

– ε is the permittivity of the material

– ε0 is the permittivity of free space (vacuum), which has a value of approximately 8.85 × 10^-12 F/m

Dielectric Constant of FR4

FR4 is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. The dielectric constant of FR4 can vary depending on several factors, such as the frequency of the applied electric field, temperature, and moisture content.

Typical Values

The typical dielectric constant of FR4 at room temperature and at frequencies up to 1 GHz is approximately 4.2 to 4.5. This value is an average and can vary slightly depending on the specific manufacturer and the grade of FR4 used.

| Frequency Range | Dielectric Constant (εr) |

|---|---|

| 1 MHz – 500 MHz | 4.2 – 4.5 |

| 1 GHz – 10 GHz | 4.1 – 4.3 |

It’s important to note that the dielectric constant of FR4 is not constant across all frequencies. As the frequency increases, the dielectric constant tends to decrease slightly. This phenomenon is known as dielectric dispersion.

Factors Affecting Dielectric Constant

Several factors can influence the dielectric constant of FR4:

-

Frequency: As mentioned earlier, the dielectric constant of FR4 decreases slightly with increasing frequency. This is due to the dielectric relaxation phenomena, where the polarization of the material lags behind the applied electric field at higher frequencies.

-

Temperature: The dielectric constant of FR4 is temperature-dependent. As the temperature increases, the dielectric constant also increases slightly. This is because the increased thermal energy allows for easier polarization of the material.

-

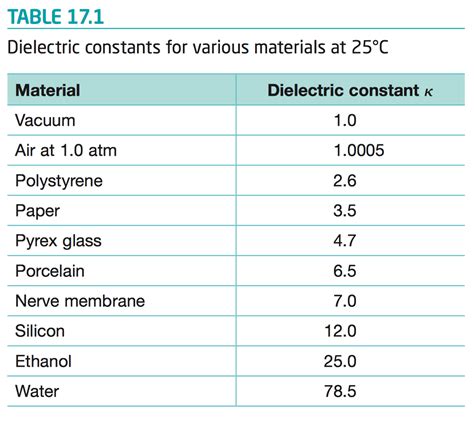

Moisture Content: Moisture absorption can significantly impact the dielectric constant of FR4. As the material absorbs moisture from the environment, its dielectric constant increases. This is because water has a much higher dielectric constant (approximately 80) compared to FR4.

-

Resin Content: The ratio of epoxy resin to fiberglass in FR4 can also affect its dielectric constant. A higher resin content generally results in a slightly lower dielectric constant.

Importance of Dielectric Constant in PCB Design

The dielectric constant of FR4 plays a crucial role in PCB design, particularly in high-frequency and high-speed applications. Here are some key reasons why understanding and considering the dielectric constant is essential:

-

Signal Integrity: The dielectric constant directly affects the speed of signal propagation on the PCB traces. A lower dielectric constant allows for faster signal propagation, reducing signal delay and improving overall signal integrity.

-

Impedance Control: The characteristic impedance of a PCB trace is dependent on the dielectric constant of the substrate material. Properly designing and controlling the impedance of traces is crucial for maintaining signal integrity and minimizing reflections.

-

Crosstalk Reduction: A lower dielectric constant helps reduce the capacitive coupling between adjacent traces, minimizing crosstalk and signal interference.

-

EMI/EMC Compliance: The dielectric constant of the PCB substrate can impact the electromagnetic compatibility (EMC) and electromagnetic interference (EMI) performance of the circuit. Proper material selection and layout techniques considering the dielectric constant can help meet EMI/EMC requirements.

Measuring Dielectric Constant

There are several methods to measure the dielectric constant of FR4 and other PCB materials. Some common techniques include:

-

Capacitance Method: This method involves measuring the capacitance of a parallel plate capacitor with the FR4 material as the dielectric. By knowing the dimensions of the capacitor and the measured capacitance, the dielectric constant can be calculated.

-

Resonance Method: In this method, a resonant cavity or a ring resonator is constructed using the FR4 material. By measuring the resonant frequency and knowing the dimensions of the structure, the dielectric constant can be determined.

-

Time Domain Reflectometry (TDR): TDR is a technique that involves sending a fast-rising voltage step through a transmission line and measuring the reflected waveform. By analyzing the reflection coefficients and propagation delay, the dielectric constant can be extracted.

-

Dielectric Probe Method: This method uses a specialized dielectric probe that is inserted into the FR4 material. The probe measures the complex permittivity of the material over a wide frequency range.

Accurate measurement of the dielectric constant is crucial for precise PCB design and simulation. PCB designers often rely on the data provided by the material manufacturers or conduct their own measurements to ensure the accuracy of their design models.

FAQ

-

Q: What is the typical dielectric constant of FR4?

A: The typical dielectric constant of FR4 at room temperature and frequencies up to 1 GHz is approximately 4.2 to 4.5. -

Q: Does the dielectric constant of FR4 change with frequency?

A: Yes, the dielectric constant of FR4 decreases slightly with increasing frequency due to dielectric dispersion. -

Q: How does moisture affect the dielectric constant of FR4?

A: Moisture absorption can significantly increase the dielectric constant of FR4 because water has a much higher dielectric constant compared to FR4. -

Q: Why is the dielectric constant important in PCB design?

A: The dielectric constant affects signal propagation speed, impedance control, crosstalk reduction, and EMI/EMC performance of the PCB. -

Q: How can the dielectric constant of FR4 be measured?

A: The dielectric constant of FR4 can be measured using methods such as the capacitance method, resonance method, time-domain reflectometry (TDR), and dielectric probe method.

Conclusion

The dielectric constant of FR4 is a critical parameter in PCB design, influencing signal integrity, impedance control, and overall circuit performance. With a typical value ranging from 4.2 to 4.5, FR4 provides a balanced compromise between electrical performance and manufacturability.

However, it’s essential to consider the factors that can affect the dielectric constant, such as frequency, temperature, and moisture content, to ensure optimal PCB design. By understanding the dielectric constant and its implications, PCB designers can make informed decisions regarding material selection, layout, and simulation, ultimately leading to more reliable and high-performance electronic products.

As the demand for high-speed and high-frequency electronics continues to grow, the importance of accurate dielectric constant characterization and consideration in PCB design will only increase. Staying up-to-date with the latest materials, measurement techniques, and design practices related to dielectric constant will be crucial for engineers and designers to meet the evolving challenges in the electronics industry.

No responses yet