What is Dielectric Strength?

Dielectric strength, also known as the breakdown voltage, is a measure of a material’s ability to resist electrical breakdown under an applied electric field. It is expressed in volts per unit thickness, typically volts per mil (V/mil) or kilovolts per millimeter (kV/mm). A material with a higher dielectric strength can withstand higher voltages before experiencing electrical breakdown, making it a better insulator.

Factors Affecting Dielectric Strength

Several factors can influence the dielectric strength of a material, including:

-

Material composition: The chemical composition and purity of the material play a significant role in determining its dielectric strength. Impurities or defects in the material can lead to localized electrical stress, reducing the overall dielectric strength.

-

Thickness: The dielectric strength of a material is inversely proportional to its thickness. As the thickness of the material increases, its ability to withstand high voltages decreases.

-

Temperature: The dielectric strength of a material can decrease with increasing temperature. At higher temperatures, the thermal energy of the molecules increases, making it easier for electrical breakdown to occur.

-

Frequency: The dielectric strength of a material can also vary with the frequency of the applied voltage. Some materials may exhibit lower dielectric strength at higher frequencies.

-

Humidity: Moisture content in the material can significantly impact its dielectric strength. Water molecules can create conductive pathways, reducing the material’s ability to insulate and increasing the likelihood of electrical breakdown.

Dielectric Strength of FR4

FR4 is a composite material consisting of a woven fiberglass fabric impregnated with an epoxy resin. The combination of these materials gives FR4 its excellent mechanical, thermal, and electrical properties, making it a popular choice for PCB substrates.

The dielectric strength of FR4 varies depending on the specific grade and manufacturer. However, typical values for the dielectric strength of FR4 range from 20 to 28 kV/mm (500 to 800 V/mil). This means that an FR4 board with a thickness of 1.6 mm (63 mil) can withstand voltages between 32 and 45 kV before experiencing electrical breakdown.

Comparison with Other PCB Materials

FR4 is not the only material used in PCB manufacturing. Other common materials include:

-

Polyimide: Polyimide is a high-performance polymer known for its excellent thermal stability and high dielectric strength. Its dielectric strength can range from 100 to 200 kV/mm, making it suitable for applications requiring higher voltage insulation.

-

Ceramic: Ceramic substrates, such as alumina (Al2O3), offer superior thermal conductivity and high dielectric strength. Alumina has a dielectric strength of approximately 20 to 30 kV/mm, similar to FR4. However, ceramic substrates are more expensive and brittle compared to FR4.

-

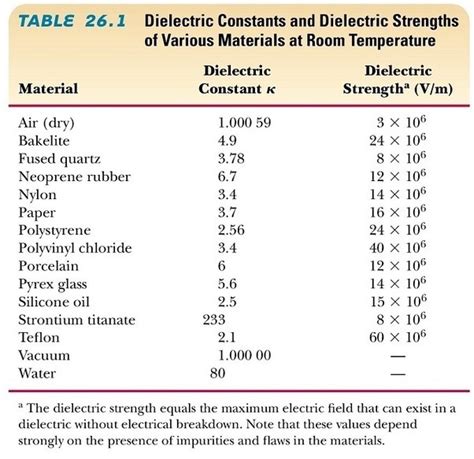

PTFE (Teflon): PTFE, or polytetrafluoroethylene, is a fluoropolymer known for its low dielectric constant and high dielectric strength. Its dielectric strength can range from 60 to 173 kV/mm, making it an excellent insulator for high-frequency applications.

The table below summarizes the dielectric strength values for these materials:

| Material | Dielectric Strength (kV/mm) |

|---|---|

| FR4 | 20 – 28 |

| Polyimide | 100 – 200 |

| Alumina | 20 – 30 |

| PTFE | 60 – 173 |

Importance of Dielectric Strength in PCB Design

Understanding the dielectric strength of FR4 and other PCB materials is crucial for designers and engineers when developing electronic circuits. Here are some reasons why dielectric strength is important:

-

Insulation: The primary function of the PCB substrate is to provide electrical insulation between conductive traces and layers. A material with a high dielectric strength ensures that the board can withstand the required voltages without experiencing electrical breakdown, preventing short circuits and other failures.

-

High-voltage applications: In applications involving high voltages, such as power electronics or automotive systems, selecting a material with the appropriate dielectric strength is critical. FR4 may not be suitable for extremely high-voltage applications, and designers may need to consider alternative materials like polyimide or ceramic.

-

Safety: Ensuring the safety of users and preventing electrical hazards is a top priority in electronic design. By selecting a material with an adequate dielectric strength, designers can minimize the risk of electrical shock and fire hazards.

-

Reliability: A PCB substrate with a high dielectric strength contributes to the overall reliability of the electronic device. It reduces the likelihood of insulation breakdown and helps maintain the integrity of the circuit over its lifetime.

Testing Dielectric Strength

To determine the dielectric strength of a material, standardized testing methods are employed. The most common method is the ASTM D149 standard, which involves applying a voltage across the thickness of the material and gradually increasing it until electrical breakdown occurs. The voltage at which breakdown occurs is recorded, and the dielectric strength is calculated by dividing the breakdown voltage by the thickness of the material.

It is essential to follow proper safety protocols and use appropriate equipment when conducting dielectric strength tests, as high voltages can pose significant safety hazards.

Conclusion

In conclusion, the dielectric strength of FR4 is a critical property that determines its ability to insulate and withstand high voltages in PCB applications. With typical values ranging from 20 to 28 kV/mm, FR4 is suitable for most general-purpose electronic designs. However, for applications requiring higher voltage insulation, alternative materials like polyimide or PTFE may be considered.

Understanding the factors affecting dielectric strength, such as material composition, thickness, temperature, frequency, and humidity, helps designers make informed decisions when selecting PCB materials. By choosing a material with the appropriate dielectric strength, designers can ensure the safety, reliability, and performance of their electronic devices.

Frequently Asked Questions (FAQ)

-

What is the typical dielectric strength of FR4?

The typical dielectric strength of FR4 ranges from 20 to 28 kV/mm (500 to 800 V/mil). -

Can FR4 be used for high-voltage applications?

While FR4 is suitable for most general-purpose electronic applications, it may not be the best choice for extremely high-voltage applications. In such cases, materials with higher dielectric strength, like polyimide or ceramic, may be more appropriate. -

How does the thickness of FR4 affect its dielectric strength?

The dielectric strength of FR4 is inversely proportional to its thickness. As the thickness of the FR4 board increases, its ability to withstand high voltages decreases. -

What safety precautions should be taken when testing the dielectric strength of materials?

When testing the dielectric strength of materials, it is crucial to follow proper safety protocols and use appropriate equipment. High voltages can pose significant safety hazards, so tests should be conducted by trained professionals in a controlled environment with the necessary safety measures in place. -

How does the dielectric strength of FR4 compare to other PCB materials?

FR4 has a dielectric strength similar to that of alumina ceramic substrates (20-30 kV/mm) but lower than polyimide (100-200 kV/mm) and PTFE (60-173 kV/mm). The choice of material depends on the specific requirements of the application, such as the required voltage insulation, thermal stability, and cost considerations.

No responses yet