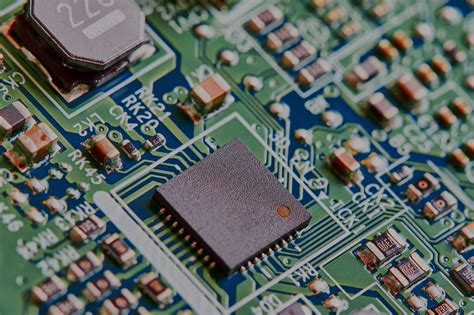

What is a Circuit board?

A circuit board is a flat, insulating board made of materials like fiberglass, epoxy, or composite substrates. It consists of conductive pathways, typically made of copper, that are etched or printed onto the board’s surface. These pathways, called traces, connect various electronic components such as resistors, capacitors, integrated circuits (ICs), and other elements to form a complete electronic circuit.

Types of Circuit Boards

There are several types of circuit boards, each with its own characteristics and applications:

-

Single-sided PCBs: These boards have conductive traces on only one side of the substrate. They are the simplest and most cost-effective type of PCB, suitable for basic electronic projects.

-

Double-sided PCBs: These boards have conductive traces on both sides of the substrate, allowing for more complex circuits and higher component density. The two sides are connected through holes called vias.

-

Multi-layer PCBs: These boards consist of multiple layers of conductive traces separated by insulating layers. They offer even higher component density and are used in complex electronic systems that require compact packaging.

-

Flexible PCBs: These boards are made of flexible materials like polyimide, allowing them to bend and conform to various shapes. They are commonly used in applications where flexibility and space constraints are crucial, such as wearable devices and automotive electronics.

-

Rigid-Flex PCBs: These boards combine the features of rigid and flexible PCBs, consisting of both rigid and flexible sections. They offer the benefits of both types, providing flexibility where needed while maintaining structural integrity in other areas.

Circuit board manufacturing Process

The manufacturing process of circuit boards involves several steps to ensure high-quality and reliable boards. Here’s an overview of the main steps involved:

-

Design: The circuit board design is created using specialized software called Electronic Design Automation (EDA) tools. The design includes the layout of the traces, component placement, and other necessary features.

-

Substrate Preparation: The substrate material, typically a thin, insulating board, is cut to the desired size and shape. Holes for mounting components and vias are drilled into the substrate.

-

Copper Cladding: A thin layer of copper is laminated onto the substrate using heat and pressure. This copper layer will form the conductive traces on the board.

-

Photoresist Application: A photosensitive material called photoresist is applied to the copper-clad substrate. This material hardens when exposed to light.

-

Exposure and Development: The circuit board design is transferred onto the photoresist using a photolithography process. The exposed areas of the photoresist harden, while the unexposed areas remain soluble.

-

Etching: The board is then exposed to an etchant solution that removes the unwanted copper, leaving behind the desired conductive traces.

-

Soldermask and Silkscreen: A soldermask layer is applied to the board to protect the copper traces and prevent short circuits. A silkscreen layer is then added to provide component labels and other markings.

-

Surface Finish: A surface finish, such as HAL (Hot Air Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), is applied to the exposed copper to prevent oxidation and improve solderability.

-

Assembly: The electronic components are placed and soldered onto the circuit board using automated pick-and-place machines and reflow soldering techniques.

-

Testing and Inspection: The assembled circuit boards undergo various tests and inspections to ensure functionality, quality, and reliability. This may include automated optical inspection (AOI), X-ray inspection, and functional testing.

Applications of Circuit Boards

Circuit boards find applications in a wide range of electronic devices and systems, spanning various industries and sectors. Some common applications include:

-

Consumer Electronics: Circuit boards are the backbone of consumer electronic devices such as smartphones, tablets, laptops, televisions, gaming consoles, and smart home appliances.

-

Automotive Electronics: Modern vehicles heavily rely on electronic systems for engine control, infotainment, safety features, and advanced driver assistance systems (ADAS). Circuit boards play a crucial role in enabling these functionalities.

-

Industrial Automation: Circuit boards are used in industrial control systems, programmable logic controllers (PLCs), sensors, and automation equipment to control and monitor industrial processes.

-

Medical Devices: Circuit boards are essential components in medical equipment such as patient monitors, imaging systems, surgical instruments, and implantable devices.

-

Aerospace and Defense: Circuit boards are used in avionics systems, satellite communications, radar systems, and military equipment, where reliability and performance are of utmost importance.

-

Internet of Things (IoT): The proliferation of IoT devices, such as smart sensors, wearables, and connected devices, relies heavily on compact and efficient circuit boards to enable data collection, processing, and communication.

-

Renewable Energy: Circuit boards are used in solar inverters, wind turbine control systems, and energy storage systems to manage and optimize renewable energy generation and distribution.

Importance of Circuit Boards

Circuit boards play a vital role in the functioning and advancement of modern electronic devices and systems. Here are some key reasons why circuit boards are important:

-

Miniaturization: Circuit boards enable the miniaturization of electronic devices by providing a compact platform for integrating various components. This allows for the development of smaller, more portable, and more efficient devices.

-

Reliability: Well-designed and properly manufactured circuit boards ensure reliable connections between components, reducing the risk of short circuits, signal interference, and other issues that could compromise the device’s performance.

-

Scalability: Circuit boards facilitate the scalability of electronic systems by allowing for modular designs and easy integration of additional components or features as needed.

-

Cost-effectiveness: Mass production of circuit boards using automated manufacturing processes reduces the overall cost of electronic devices, making them more accessible and affordable.

-

Innovation: Circuit boards provide a foundation for innovation in the electronics industry, enabling the development of new technologies, features, and applications.

Frequently Asked Questions (FAQ)

-

What is the difference between a PCB and a circuit board?

A: PCB (Printed Circuit Board) and circuit board are often used interchangeably. A PCB is a specific type of circuit board where the conductive traces are printed or etched onto the insulating substrate. -

Can circuit boards be repaired?

A: Yes, circuit boards can be repaired, depending on the extent of the damage and the complexity of the board. Common repair techniques include soldering, trace repair, and component replacement. -

How long do circuit boards last?

A: The lifespan of a circuit board depends on various factors, such as the quality of manufacturing, environmental conditions, and usage. Generally, well-designed and properly maintained circuit boards can last for several years or even decades. -

What is the most common material used for circuit boards?

A: The most common material used for circuit board substrates is FR-4, which is a composite material made of fiberglass and epoxy resin. FR-4 provides good insulation, mechanical strength, and thermal stability. -

Can circuit boards be recycled?

A: Yes, circuit boards can be recycled to recover valuable materials such as copper, gold, and other precious metals. However, the recycling process is complex and requires specialized facilities to handle the various components and materials safely.

| Type of Circuit Board | Characteristics | Applications |

|---|---|---|

| Single-sided PCBs | Conductive traces on one side only | Simple electronic projects, low-cost devices |

| Double-sided PCBs | Conductive traces on both sides, connected through vias | More complex circuits, higher component density |

| Multi-layer PCBs | Multiple layers of conductive traces separated by insulating layers | Complex electronic systems, compact packaging |

| Flexible PCBs | Made of flexible materials, can bend and conform to shapes | Wearable devices, automotive electronics, space-constrained applications |

| Rigid-Flex PCBs | Combination of rigid and flexible sections | Applications requiring both flexibility and structural integrity |

In conclusion, circuit boards are the foundation of modern electronics, providing a platform for integrating and connecting various components to create functional electronic devices and systems. They play a crucial role in enabling miniaturization, reliability, scalability, cost-effectiveness, and innovation in the electronics industry. As technology continues to advance, the importance of circuit boards will only grow, driving the development of new and innovative electronic solutions across various sectors and applications.

No responses yet