What is Dielectric constant?

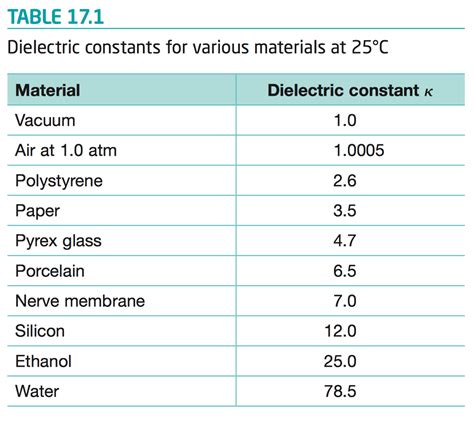

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electric energy in an electric field. It is the ratio of the permittivity of a substance to the permittivity of free space. In other words, it indicates how easily a material can become polarized by an applied electric field.

The dielectric constant is a unitless quantity and is typically denoted by the Greek letter epsilon (ε). A vacuum has a dielectric constant of exactly 1. All other materials have dielectric constants greater than 1.

Importance of Dielectric Constant in PCB Design

In PCB design, the dielectric constant of the substrate material is a critical factor that affects signal integrity, impedance control, and power handling. A lower dielectric constant means that the material has less capacitance, which allows for faster signal propagation and lower signal loss.

The dielectric constant also influences the characteristic impedance of transmission lines on a PCB. The characteristic impedance (Z0) is determined by the trace width, trace thickness, substrate thickness, and dielectric constant of the substrate material. Achieving the desired characteristic impedance is essential for impedance matching and minimizing signal reflections.

Dielectric Constant of Rogers 4835

Rogers 4835 is a hydrocarbon ceramic laminate material designed for high frequency applications. It offers excellent thermal and electrical properties, making it suitable for demanding PCB designs.

Dielectric Constant Value

The dielectric constant of Rogers 4835 is specified as follows:

| Condition | Dielectric Constant (εr) |

|---|---|

| Design Value (Process) | 3.48 ± 0.05 |

| Specification Limits | 3.33 – 3.63 |

The design value represents the typical dielectric constant of Rogers 4835 under standard processing conditions. The specification limits indicate the acceptable range of dielectric constant values for the material.

It’s important to note that the dielectric constant of Rogers 4835 is stable over a wide frequency range, from 1 MHz to 10 GHz. This stability ensures consistent performance across different operating frequencies.

Comparison with Other PCB Materials

To put the dielectric constant of Rogers 4835 into perspective, let’s compare it with some other common PCB materials:

| Material | Dielectric Constant (εr) |

|---|---|

| Rogers 4835 | 3.48 |

| Rogers 4003C | 3.38 |

| FR-4 | 4.5 |

| Rogers RO4350B | 3.48 |

| Rogers RO4000 | 3.38 – 3.48 |

As you can see, Rogers 4835 has a dielectric constant similar to Rogers RO4350B and falls within the range of Rogers RO4000 series materials. It has a lower dielectric constant compared to FR-4, which is a standard PCB material for lower frequency applications.

Impact of Dielectric Constant on PCB Performance

The dielectric constant of the substrate material has a significant impact on various aspects of PCB performance. Let’s explore some of these effects:

Signal Propagation Velocity

The dielectric constant directly affects the signal propagation velocity in a PCB. The velocity of propagation (v) is inversely proportional to the square root of the dielectric constant:

v = c / √εr

where:

– v is the velocity of propagation

– c is the speed of light in vacuum (approximately 3 × 10^8 m/s)

– εr is the dielectric constant of the substrate material

A lower dielectric constant results in faster signal propagation velocity. This is particularly important for high-speed digital circuits where signals need to travel quickly across the PCB.

Characteristic Impedance

The dielectric constant also affects the characteristic impedance of transmission lines on a PCB. The characteristic impedance (Z0) is given by:

Z0 = (87 / √εr) × ln(5.98 × h / (0.8 × w + t))

where:

– Z0 is the characteristic impedance in ohms (Ω)

– εr is the dielectric constant of the substrate material

– h is the substrate thickness in inches

– w is the trace width in inches

– t is the trace thickness in inches

A higher dielectric constant results in a lower characteristic impedance for a given trace geometry. Therefore, when designing impedance-controlled transmission lines, the dielectric constant must be considered along with the trace dimensions to achieve the desired characteristic impedance.

Wavelength and Electrical Length

The dielectric constant impacts the wavelength and electrical length of signals in a PCB. The wavelength (λ) is given by:

λ = c / (f × √εr)

where:

– λ is the wavelength in meters

– c is the speed of light in vacuum (approximately 3 × 10^8 m/s)

– f is the frequency in hertz (Hz)

– εr is the dielectric constant of the substrate material

A higher dielectric constant results in a shorter wavelength for a given frequency. This is important when designing antenna structures or calculating the electrical length of transmission lines.

The electrical length (EL) of a transmission line is the physical length expressed in terms of wavelength:

EL = l / λ

where:

– EL is the electrical length in radians or degrees

– l is the physical length of the transmission line in meters

– λ is the wavelength in meters

A shorter wavelength due to a higher dielectric constant means that a given physical length corresponds to a larger electrical length. This must be considered when designing phase-sensitive circuits or matching network elements.

Measuring Dielectric Constant

Accurate knowledge of the dielectric constant is crucial for PCB design and simulation. There are several methods for measuring the dielectric constant of a material:

Cavity Perturbation Method

The cavity perturbation method involves placing a small sample of the material inside a resonant cavity and measuring the change in resonant frequency. The dielectric constant can be calculated from the frequency shift and the sample dimensions.

Transmission Line Method

The transmission line method involves fabricating a transmission line structure on the substrate material and measuring its electrical properties, such as the phase velocity or characteristic impedance. The dielectric constant can be derived from these measurements using appropriate equations.

Capacitance Method

The capacitance method involves measuring the capacitance of a parallel plate capacitor formed by the substrate material. The dielectric constant can be calculated from the measured capacitance, plate area, and plate separation.

Resonance Method

The resonance method involves measuring the resonant frequency and quality factor (Q) of a resonator structure fabricated on the substrate material. The dielectric constant can be determined from the resonant frequency, resonator dimensions, and quality factor.

Factors Affecting Dielectric Constant

The dielectric constant of a material can be influenced by various factors, including:

Frequency

The dielectric constant of a material can vary with frequency due to dielectric relaxation mechanisms. Rogers 4835, however, exhibits a stable dielectric constant over a wide frequency range.

Temperature

The dielectric constant of a material can change with temperature. Rogers 4835 has a stable dielectric constant over a wide temperature range, from -50°C to +150°C.

Moisture

Moisture absorption can affect the dielectric constant of a material. Rogers 4835 has a low moisture absorption rate of 0.02% and maintains its dielectric constant even in humid environments.

Anisotropy

Some materials exhibit anisotropic dielectric properties, meaning that the dielectric constant varies depending on the direction of the electric field. Rogers 4835 is an isotropic material, with consistent dielectric properties in all directions.

FAQ

-

What is the dielectric constant of Rogers 4835?

The design value of the dielectric constant of Rogers 4835 is 3.48 ± 0.05, with specification limits of 3.33 to 3.63. -

Is the dielectric constant of Rogers 4835 stable over frequency?

Yes, Rogers 4835 exhibits a stable dielectric constant over a wide frequency range, from 1 MHz to 10 GHz. -

How does the dielectric constant affect signal propagation velocity?

The signal propagation velocity is inversely proportional to the square root of the dielectric constant. A lower dielectric constant results in faster signal propagation velocity. -

What factors can influence the dielectric constant of a material?

The dielectric constant of a material can be influenced by factors such as frequency, temperature, moisture, and anisotropy. However, Rogers 4835 is designed to maintain a stable dielectric constant under various conditions. -

How can the dielectric constant of a material be measured?

The dielectric constant of a material can be measured using methods such as the cavity perturbation method, transmission line method, capacitance method, and resonance method. Each method involves specific measurement techniques and calculations.

Conclusion

The dielectric constant of Rogers 4835 is a critical parameter for high frequency PCB design. With a design value of 3.48 ± 0.05 and stable performance over a wide frequency range, Rogers 4835 offers excellent electrical properties for demanding applications.

Understanding the impact of dielectric constant on signal propagation velocity, characteristic impedance, wavelength, and electrical length is essential for successful PCB design. By considering the dielectric constant along with other material properties and design factors, engineers can optimize signal integrity, impedance control, and overall circuit performance.

Accurate measurement of the dielectric constant using appropriate methods ensures reliable design and simulation results. Rogers 4835, with its stable dielectric constant and low moisture absorption, provides a reliable substrate material for high frequency PCBs.

By leveraging the knowledge of the dielectric constant and its effects on PCB performance, designers can make informed decisions and create robust, high-performance circuits using Rogers 4835 and other advanced substrate materials.

No responses yet