Introduction to PCB thickness

Printed Circuit Board (PCB) thickness is a crucial factor in the design and manufacturing of electronic devices. It plays a significant role in determining the mechanical strength, thermal management, and electrical performance of the PCB. The thickness of a PCB can vary depending on the application, the number of layers, and the manufacturing process used.

In this article, we will explore the range of PCB thickness, the factors that influence it, and the impact it has on the overall performance of the PCB.

Factors Influencing PCB Thickness

Several factors influence the thickness of a PCB, including:

Number of Layers

The number of layers in a PCB is one of the primary factors that determine its thickness. A single-layer PCB is the thinnest, while a multi-layer PCB can be much thicker. Each additional layer adds to the overall thickness of the PCB.

Copper Weight

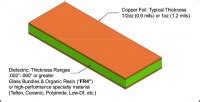

The weight of the copper used in the PCB also affects its thickness. Copper weight is measured in ounces per square foot (oz/ft²). The most common copper weights used in PCBs are 1 oz/ft² and 2 oz/ft², but heavier copper weights, such as 3 oz/ft² and 4 oz/ft², can also be used for high-power applications.

Substrate Material

The substrate material used in the PCB also influences its thickness. The most common substrate materials used in PCBs are:

- FR-4: A glass-reinforced epoxy laminate that is the most widely used substrate material for PCBs.

- Polyimide: A high-temperature substrate material used in applications where the PCB needs to withstand extreme temperatures.

- Teflon: A low-loss substrate material used in high-frequency applications.

Manufacturing Process

The manufacturing process used to create the PCB also affects its thickness. The most common manufacturing processes used for PCBs are:

- Through-hole technology (THT): A process where components are inserted into drilled holes in the PCB and soldered onto the opposite side.

- Surface-mount technology (SMT): A process where components are mounted directly onto the surface of the PCB.

Standard PCB Thickness

The standard thickness of a PCB is usually measured in mils (thousandths of an inch). The most common PCB thicknesses are:

| PCB Thickness (mils) | PCB Thickness (mm) |

|---|---|

| 0.4 | 0.0101 |

| 0.6 | 0.0152 |

| 0.8 | 0.0203 |

| 1.0 | 0.0254 |

| 1.2 | 0.0305 |

| 1.6 | 0.0406 |

| 2.0 | 0.0508 |

| 2.4 | 0.0610 |

| 3.2 | 0.0813 |

Single-layer PCBs

Single-layer PCBs are the thinnest and most basic type of PCB. They consist of a single layer of substrate material with copper traces on one side and components on the other. The standard thickness for single-layer PCBs is usually 0.6 mils to 1.6 mils.

Double-layer PCBs

Double-layer PCBs have copper traces on both sides of the substrate material. They are thicker than single-layer PCBs and offer more design flexibility. The standard thickness for double-layer PCBs is usually 0.8 mils to 2.0 mils.

Multi-layer PCBs

Multi-layer PCBs have three or more layers of substrate material with copper traces on each layer. They are used in complex electronic devices that require a high degree of interconnectivity. The thickness of a multi-layer PCB depends on the number of layers and the application. The standard thickness for multi-layer PCBs can range from 0.6 mils to 3.2 mils or more.

Impact of PCB Thickness on Performance

Mechanical Strength

The thickness of a PCB affects its mechanical strength. Thicker PCBs are more rigid and less prone to warping and twisting. This is especially important in applications where the PCB is subjected to physical stress, such as in automotive or aerospace electronics.

Thermal Management

The thickness of a PCB also affects its thermal management properties. Thicker PCBs have better thermal conductivity and can dissipate heat more efficiently. This is important in high-power applications where the PCB needs to handle large amounts of current.

Electrical Performance

The thickness of a PCB can also impact its electrical performance. Thicker PCBs have lower electrical resistance and can handle higher currents. However, thicker PCBs also have higher capacitance and can affect the signal integrity of high-frequency signals.

Choosing the Right PCB Thickness

Choosing the right PCB thickness depends on several factors, including:

- The application of the PCB

- The number of layers required

- The power requirements of the circuit

- The mechanical and environmental stresses the PCB will be subjected to

For example, a single-layer PCB may be sufficient for a simple, low-power circuit, while a multi-layer PCB may be necessary for a complex, high-power circuit.

It is important to work with a PCB manufacturer to determine the optimal thickness for your specific application. They can provide guidance on the best substrate material, copper weight, and manufacturing process to use based on your requirements.

FAQ

What is the thinnest possible PCB thickness?

The thinnest possible PCB thickness is 0.4 mils (0.0101 mm). However, this thickness is not commonly used and may not be suitable for most applications.

What is the thickest possible PCB thickness?

The thickest possible PCB thickness depends on the manufacturing process and the application. Some PCB manufacturers can produce PCBs with thicknesses up to 300 mils (7.62 mm) or more for specialized applications.

How does PCB thickness affect the cost of manufacturing?

In general, thicker PCBs are more expensive to manufacture than thinner PCBs. This is because they require more substrate material, copper, and processing time. However, the cost also depends on other factors, such as the number of layers, the size of the PCB, and the volume of the order.

Can PCB thickness be customized?

Yes, PCB thickness can be customized to meet specific application requirements. PCB manufacturers can work with you to determine the optimal thickness for your specific application based on factors such as power requirements, mechanical stress, and environmental conditions.

How does PCB thickness affect the weight of the PCB?

The thickness of a PCB directly affects its weight. Thicker PCBs are heavier than thinner PCBs due to the additional substrate material and copper used in their construction. This can be an important consideration in applications where weight is a critical factor, such as in aerospace or portable electronics.

Conclusion

PCB thickness is a critical factor in the design and manufacturing of electronic devices. It affects the mechanical strength, thermal management, and electrical performance of the PCB. The range of PCB thickness can vary depending on the application, the number of layers, and the manufacturing process used.

When choosing the right PCB thickness for your application, it is important to consider factors such as power requirements, mechanical stress, and environmental conditions. Working with a PCB manufacturer can help you determine the optimal thickness for your specific needs.

By understanding the range of PCB thickness and its impact on performance, you can make informed decisions when designing and manufacturing electronic devices.

No responses yet