PCB composition Overview

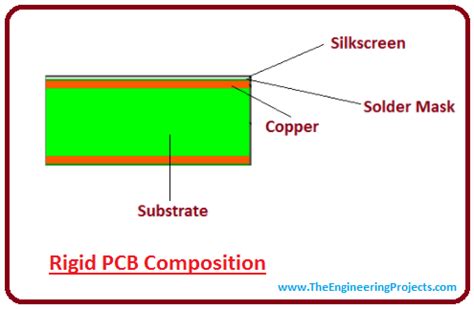

A typical PCB consists of several layers of materials, each serving a specific purpose. The main components of a PCB include:

- Substrate (base material)

- Copper foil

- Soldermask

- Silkscreen

- Surface finish

Let’s take a closer look at each of these components and their roles in PCB composition.

Substrate (Base Material)

The substrate, also known as the base material, is the foundation of a PCB. It provides mechanical support and electrical insulation for the copper traces and components. The most common substrate materials used in PCB manufacturing are:

FR-4

FR-4 (Flame Retardant 4) is the most widely used substrate material for PCBs. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. FR-4 offers excellent mechanical strength, electrical insulation, and thermal stability. It is suitable for a wide range of applications, from consumer electronics to industrial equipment.

| Property | Value |

|---|---|

| Dielectric Constant | 4.5 (at 1 MHz) |

| Dissipation Factor | 0.02 |

| Thermal Conductivity | 0.25 W/(m·K) |

| Tensile Strength | 310 MPa |

| Glass Transition Temperature (Tg) | 135 °C |

Polyimide

Polyimide is a high-performance substrate material used in applications that demand superior thermal stability and mechanical strength. It is often used in aerospace, military, and high-temperature electronics. Polyimide has a higher glass transition temperature (Tg) compared to FR-4, making it suitable for environments with extreme temperatures.

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 (at 1 MHz) |

| Dissipation Factor | 0.002 |

| Thermal Conductivity | 0.35 W/(m·K) |

| Tensile Strength | 231 MPa |

| Glass Transition Temperature (Tg) | 360 °C |

Teflon (PTFE)

Teflon, or Polytetrafluoroethylene (PTFE), is a fluoropolymer known for its low dielectric constant and excellent chemical resistance. It is used in high-frequency and microwave applications, where signal integrity is critical. Teflon-based substrates are more expensive than FR-4 and polyimide, but they offer superior electrical properties.

| Property | Value |

|---|---|

| Dielectric Constant | 2.1 (at 1 MHz) |

| Dissipation Factor | 0.0002 |

| Thermal Conductivity | 0.25 W/(m·K) |

| Tensile Strength | 23 MPa |

| Glass Transition Temperature (Tg) | 327 °C |

Copper Foil

Copper foil is the conductive layer of a PCB, responsible for carrying electrical signals between components. It is laminated onto the substrate material using heat and pressure. The thickness of the copper foil is typically measured in ounces per square foot (oz/ft²), with common thicknesses ranging from 0.5 oz/ft² to 2 oz/ft².

The copper foil used in PCBs is usually electrodeposited (ED) or rolled annealed (RA) copper. ED copper is formed by electroplating copper onto a rotating drum, while RA copper is produced by rolling copper ingots into thin sheets and annealing them to improve ductility.

| Property | ED Copper | RA Copper |

|---|---|---|

| Tensile Strength | 260-300 MPa | 250-290 MPa |

| Elongation | 8-16% | 12-20% |

| Yield Strength | 140-180 MPa | 120-150 MPa |

| Grain Size | Small | Large |

| Surface Roughness | High | Low |

Soldermask

Soldermask, also known as solder resist, is a thin layer of polymer applied over the copper traces and pads. Its primary functions are to protect the copper from oxidation, prevent solder bridges between closely spaced pads, and provide electrical insulation. Soldermask is typically green in color, but other colors like blue, red, and black are also available.

The most common types of soldermask used in PCB manufacturing are:

Liquid Photoimageable Soldermask (LPI)

LPI soldermask is applied as a liquid and then exposed to UV light through a photomask. The exposed areas polymerize and become resistant to the developer solution, while the unexposed areas are washed away. LPI soldermask offers excellent resolution and adhesion to the copper surface.

Dry Film Soldermask (DFSM)

DFSM is a solid film that is laminated onto the PCB surface using heat and pressure. It is then exposed to UV light through a photomask and developed, similar to LPI soldermask. DFSM is less commonly used than LPI due to its lower resolution and adhesion properties.

Silkscreen

Silkscreen, also called legend or nomenclature, is a layer of ink printed on top of the soldermask. It is used to provide visual information about the components, such as their reference designators, polarity markers, and logos. Silkscreen ink is usually white, but other colors can be used for better contrast or aesthetic purposes.

The silkscreen layer is applied using a screen printing process, where the ink is forced through a fine mesh screen onto the PCB surface. The screen has a stencil of the desired pattern, allowing the ink to pass through only in the desired areas.

Surface Finish

The surface finish is a thin layer of metal applied to the exposed copper pads and through-holes of a PCB. Its primary purposes are to protect the copper from oxidation, enhance solderability, and improve the electrical and mechanical connection between the PCB and the components. The most common surface finishes used in PCB manufacturing are:

Hot Air Solder Leveling (HASL)

HASL is a process where the PCB is dipped into a molten solder bath and then exposed to hot air to level the solder on the pads and through-holes. HASL provides excellent solderability and is relatively inexpensive, but it can result in uneven surface flatness and solder bridges.

Electroless Nickel Immersion Gold (ENIG)

ENIG is a two-layer surface finish consisting of a nickel layer plated onto the copper, followed by a thin layer of gold. The nickel layer acts as a barrier to prevent copper diffusion, while the gold layer provides excellent solderability and corrosion resistance. ENIG offers a flat surface and is suitable for fine-pitch components, but it is more expensive than HASL.

Immersion Silver (IAg)

IAg is a single-layer surface finish where silver is chemically deposited onto the copper surface. It provides good solderability and is less expensive than ENIG. However, IAg is prone to tarnishing over time and may not be suitable for applications with long storage periods.

Immersion Tin (ISn)

ISn is another single-layer surface finish where tin is chemically deposited onto the copper surface. It offers excellent solderability and is less expensive than ENIG and IAg. However, ISn is prone to tin whiskers, which can cause short circuits in high-reliability applications.

PCB Composition and Manufacturing Process

The composition of a PCB is closely tied to its manufacturing process. The typical steps involved in PCB manufacturing are:

-

Design: The PCB layout is designed using CAD software, considering the electrical and mechanical requirements of the application.

-

Substrate preparation: The substrate material is cut to size, and any necessary holes are drilled.

-

Copper lamination: The copper foil is laminated onto the substrate using heat and pressure.

-

Photoresist application: A photosensitive resist is applied to the copper surface.

-

Exposure and development: The photoresist is exposed to UV light through a photomask, and the unexposed areas are removed using a developer solution.

-

Etching: The exposed copper is etched away using a chemical solution, leaving only the desired copper traces and pads.

-

Soldermask application: The soldermask is applied, exposed, and developed to protect the copper traces and provide insulation.

-

Silkscreen printing: The silkscreen layer is printed onto the soldermask to provide visual information.

-

Surface finish application: The chosen surface finish is applied to the exposed copper pads and through-holes.

-

Electrical testing: The PCB is tested for electrical continuity and functionality.

FAQs

-

Q: What is the most common substrate material used in PCBs?

A: FR-4 (Flame Retardant 4) is the most widely used substrate material for PCBs due to its excellent mechanical, electrical, and thermal properties. -

Q: What is the purpose of the soldermask layer in a PCB?

A: The soldermask layer protects the copper traces from oxidation, prevents solder bridges between closely spaced pads, and provides electrical insulation. -

Q: What are the advantages of using ENIG as a surface finish?

A: ENIG (Electroless Nickel Immersion Gold) offers a flat surface, excellent solderability, and corrosion resistance. It is suitable for fine-pitch components and high-reliability applications. -

Q: Can the silkscreen layer be printed in colors other than white?

A: Yes, while white is the most common color for silkscreen, other colors like black, yellow, or blue can be used for better contrast or aesthetic purposes. -

Q: What is the difference between ED and RA copper foils used in PCBs?

A: ED (Electrodeposited) copper foil is formed by electroplating copper onto a rotating drum, while RA (Rolled Annealed) copper foil is produced by rolling copper ingots into thin sheets and annealing them. ED copper has a smaller grain size and higher surface roughness compared to RA copper.

In conclusion, the composition of a PCB plays a crucial role in its performance, durability, and functionality. By understanding the main materials used in PCB manufacturing and their properties, engineers and designers can make informed decisions when selecting the appropriate components for their applications. As technology advances, new materials and manufacturing processes may emerge, further enhancing the capabilities of PCBs in the electronics industry.

No responses yet